1 Check under the front grille for chafing cables. These

Page 107

Page 108

If you've noticed an error in this article please click here to report it so we can fix it.

main -harness cables can be prone to rubbing as the cab moves on its suspension. Make sure that they have not become detached from their ties, and that they are re-secured after repair work. 2 There is a pre-filter on the fuel system which can easily be overlooked by the inexperienced. It is tucked away under the air induction pipe on the nearside of the engine. Neglect will cause it to become clogged, particularly if an aftermarket cab heater has been fitted to the vehicle. The drop bowl should be removed and cleaned thoroughly on a regular basis to maximise the life of the main fuel filters.

3 MAN has altered the power steering reservoir top to a clear plastic design to aid level checking. The original dip stick is still present for the definitive check and there are minimum and maximum marks on the outer casing too. In the past there has been a tendency for this reservoir to be overfilled (covering all of the filter) causing seepage.

4Hose clips come under the service inspection schedule anyway but it is also worth putting a spanner on the pipe straps on the compressor's air cooler. The same applies to the fuel injector supply pipes. Resonance can lead to fracture.

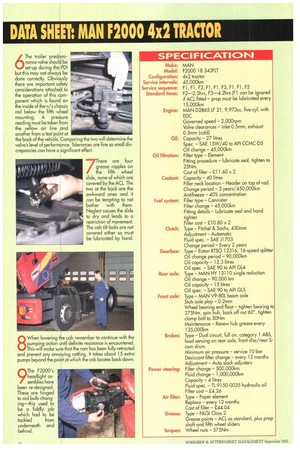

5 On this model the upper rear spring shackle on the front suspension features a metal/rubber bush. However, on 6x2 versions with shackle pins where lubrication is required it is essential that this is done properly. The lubricant must be seen to pass right down the pin and out at the other end to ensure complete coverage. Taking the weight off the shackle can make lubrication easier. 6 The trailer predominance valve should be set-up during the PDI but this may not always be done correctly. Obviously there are important safety considerations attached to the operation of this component which is found on the inside of the n/s chassis rail below the fifth wheel mounting. A pressure reading must be taken from the yellow air line and another from a test point at the back of the vehicle. Comparing the Iwo will determine the valve's level of performance. Tolerances are fine so small discrepancies can have a significant effect.

7here are four herefifth nipples w h wheel slide, none ofwhichare covered bythe ACL. The Iwo at the back are the awkward ones and it can be tempting to not bother with them. Neglect causes the slide to dry and leads to a restriction of movement. The cab tilt locks are not covered either so must be lubricated by hand.

8 When lowering the cab remember to continue with the pumping action until definite resistance is encountered. This will make sure that the ram has been fully retracted and prevent any annoying rattling. It takes about 15 extra pumps beyond the point at which the cab locates back down.

9The F2000's headlight assemblies have been re-designed. These are hinged to aid bulb changing—this used to be a fiddly job which had to be

tackled from underneath and behind.