• SCAMMELL 24-TONNER

Page 51

Page 50

Page 52

Page 53

Page 54

If you've noticed an error in this article please click here to report it so we can fix it.

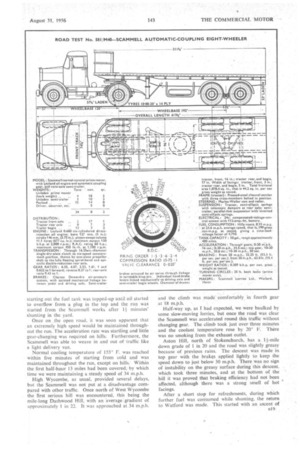

Sets the Pace

Leyland 150 b.h.p. Oil Engine in ScamMelt. 24-ton-gross Articulated Lorry • Gives High Road Speed and AutOmatte Coupling Gear Cuts Depot Delays By John F. Moon,

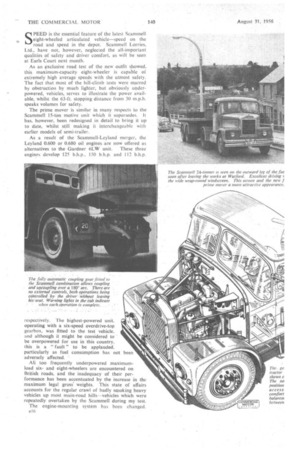

A.M.I.R.T.E. PEED is the essential feature of the latest Scammell eight-wheeled articulated vehicle—speed on the road and speed in the depot. Scammell Lorries, Ltd., have not, however, neglected the all-important qualities of safety and driver comfort, as will be seen at Earls Court next month.

As an exclusive road test of the new outfit showed. this maximum-capacity eight-wheeler is capable of extremely high average speeds with the utmost safety. The fact that most of the hill-climb tests were marred by obstruction by much lighter, but obviously under powered, vehicles, serves to illustrate the power available, whilst the 63-ft stopping distance from 30 m.p.h. speaks volumes for safety.

The prime mover is similar in many respects to the Scammell 15-ton motive unit which it supersedes. It has, however, been redesigned in detail to bring it up to date, whilst still making it interchangeable with earlier models of semi-trailer.

As a result of the Scammell-Leyland merger, the Leyland 0.600 or 0.680 oil engines are now offered as alternatives to the Gardner 6LW unit. These three engines develop 125 bh.p., 150 b.h.p. and 112 b.h.p.

respectively. The highest-powered unit. operating with a six-speed overdrive-top gearbox, was fitted to the test vehicle, and although it might be considered to be overpowered for use in this country, this is a " fault " to be applauded, particularly as fuel consumption has not been adversely affected.

All too frequently underpowered maximumload sixand eight-wheelers are encountered on British roads, and the inadequacy of their performance has been accentuated by the increase in the maximum legal gross' weights. This state of affairs accounts for the regular crawl of badly smoking heavy vehicles up most main-road hills—vehicles which were repeatedly overtaken by the Scammell during my test.

The engine-mounting system has been changed. B16

More flexible mountings are now used, consisting of Leyland rubber-bushed links at the front of the unit

and Silentbloc rubbers at the rear. They can be employed in both cross-country and on-the-road chassis with equal success.

The standard Leyland 16+-in.-diameter clutch is used in conjunction with the normal Scamtnell clutch stop. The six-speed indirect-drive gearbox is mounted separately from the engine, being connected to the clutch by a special rubber-cushioned coupling shaft. •Basically, this gearbox is similar to that used in earlier machines. but the bottom and top rittios have been 'lowered and raised respectively.

A short Hardy-Spicer-jointed propeller shaft takes the drive to the Scammell spiral-bevel epicyelie double'reduction rear axle, which has an overall ratio of 9.43 to I. The rear suspension consists of three-stage semielliptic springs working in conjunction with WoodheadMonroe telescopic dampers.

Little modification has been made to the chassis frame, being restricted to slight alteration to accom modate the automatic coupling gear. The use of normal control in this age of forward-control chassis has been retained to afford the best ratio between prime mover and semi-trailer wheelbases, and to allow maxi mum engine accessibility and tirst-rate driving conditions. Furthermore, were the prime mover to be changed to forward control it would not be interchangeable with earlier .types of semi-trailer.

: Several changes have been made in the brake system, although the size of the wheel units remains urnaltered. The air pressure has been raised from 60 p.s.i. to 80 p.s.i.

Separate air servos for the rear-axle brakes are now provided, but these act through a mechanical compensator mechanism to ensure equal braking pressure az each driving wheel and to simplify routine adjustments. By increasing the shoe centre-lift from 0.072 in. to Oil in., quicker braking reaction has been achieved and the increased shoe travel gives a greater safety margin against drum expansion and subsequent fade. The familiar Scammell radiator grille now conceals a Morris. block radiator, as opposed to the Still-tube type previously used. General appearance has been cleaned up and the most striking difference is the use of a wide two-piece wrap-round windscreen. The front wings have been modified to give a more pleasing appearance. The inside of the driving cab is now much smarter and more comfortable. A facia panel has been added which incorporates a lockable glove box, two shelves, a flush centrally mounted instrument panel, and provision for radio and heating and demisting equipment.

The driving position could hardly be bettered in a vehicle of this size. The seat is fully adjustable and the column is well raked to bring the wheel into the lap of the driver. The pedal layout has been improved and allows the use of draught seals around the stems. Three large windows are incorporated in the back panel, as against the two small ones previously provided.

A simple but substantial frame layout characterizes the semi-trailer. The side members have a maximum depth of 131 in. and the frame is cranked6 in. upwards to give turntable clearance. The principal feature, other than the coupling gear, is the parallel-link bogie.

This suspension system, which consists of a single semi-elliptic spring on each side, working in conjunction with radius links and Panhard rods, ensures maximum braking efficiency at both axles and relieves the springs from all but vertical forces. Eight special qualities of the bogie include absence of weight transference during braking; the use of spherical attachments at the spring ends to eliminate twisting of the springs on rough ground; complete lateral stability of both axles; and the reduced maintenance required because of the employment of rubber bushes and oil-bath lubrication for the central spring trunnions.

B18

In a vehicle which is full of interest it is difficult to pin-point the most important feature, but certainly the most novel is the air-operated automatic coupling gear. This was fully described in The Commercial Motor on September 24, 1954, when it was originally announced.

Briefly it may be said to resemble the mechanical coupling gear used on prime movers of up to 151 tons gross weight, in that the semi-trailer has two rollers beneath its turntable which travel up curved ramps on the back of the motive unit and are secured by a doublelocking hook.

The essential difference is that the locking hook is air operated and that the semi-trailer, when uncoupled, is supported on two air-actuated telescopic legs. When these legs are down, the mechanical linkage to the bogie brakes ensures that the semi-trailer cannot be moved Warning lights in the cab indicate • when the legs are down and the hook , disengaged; the hook cannot be released before the legs are extended.

Two controls in the cab are interlinked to provide maximum safety. Coupling and uncoupling can be carried out without the driver leaving his seat, as all air and electrical connections are automatically made.

The test vehicle was the prototype which had been brought into line with production standards. It did, however, carry a certain amount of non-standard equipment, which raised the unladen weight to 8 tons 91 cwt. With a test load of 15 tons 14 cwt. superimposed, the outfit stood at 24 tons 31 cwt. without driver and passengers. Of this weight the semi-trailer bogie wheels Were carrying 13 tons 31 cwt. between them and the driving axle had an imposed load of 8 tons 5+ cwt.

decided to make the fuel-consumption test on a route of at least 50 miles and to take in some steep hills if possible. A "convenient route from Watford through Rickmansworth and out on to the main Oxford road to Stokenchurch was chosen. It gave a return mileage of 62.

The works driver drove during this test, so that I could observe the general performance of the vehicle and take time and temperature readings. Before starting out the fuel tank was topped-up until oil started to overflow from a plug in the top and the run was started from the Scammell works after 1+ minutes' shunting in the yard.

Once on the open road, it was soon apparent that an extremely high speed would be maintained throughout the run. The acceleration rate was startling and little gear-changing was required an hills. Furthermore, the Scammell was able to weave in and out of traffic like a light delivery van.

Normal cooling temperature of 155' F. was reached within five minutes of starting from cold and was maintained throughout the run, except on hills. Within the first half-hour 13 miles had been covered, by which time we were maintaining a steady speed of 34 m.p.h.

High Wycombe, as usual, provided several delays, but the Scammell was not put at a disadvantage compared with other traffic. Once north of West Wycombe the first serious hill was encountered, this being the mile-long Dashwood Hill, with an 'average gradient of approximately 1 in 22. It was approached at 34 m.p.h. and the climb was made comfortably_ in fourth gear at '18 m.p.h.

Half-way up, as I had expected, we were baulked by some slow-moving lorries, but once the road was clear the Scammell was accelerated round this traffic without changing gear. The climb took just over three minutes and the coolant temperature rose by 20° F. There was no smoking from the exhaust outlet.

Aston Hill, north of Stokenchurch, has a 14-mile down grade of 1 in 20 and the road was slightly greasy because of previous rains. The descent was made in top gear with the brakes applied lightly to keep the speed down to just below 30 m.p.h. There was no sign of instability on the greasy surface during this descent, which took three minutes, and at the bottom of the • hill it was proved that braking efficiency had not been affected, although there was a strong smell of hot facings.

After a short stop for refreshments, during which further fuel was consumed while shunting, the return to Watford was made. This started with an ascent of aI9

.Aston Hill, which was made in fine style at 16 m.p.h. in fourth gear.

Once again the outfit was baulked half-way up, but speed was soon regained, and the climb was completed in 5+ minutes, of which five minutes was spent in fourth gear. At the top of the hill the coolant temperature was again 175° F., the ambient temperature throughout the day being 64° F.

Good time was maintained throughout the rest of the journey to Watford, despite the severe climb up Scots Hill, just outside Rickmansworth. This hill has a general gradient of 1 in 9 and is 260 yd. long. Second gear was necessary for this ascent, which was made at 5 m.p.h., and although full throttle was used the exhaust was devoid of smoke.

On arriving at the works it was found that 7.6 gal. of fuel had been consumed and that the total running time was 2 hr. 30 min. The engine had, however, been running for an additional 6 min. during parking manceuvres at each end of the test run.

Economy in Fuel

The resulting average fuel-consumption rate-8.15 m.p.g.—is extremely favourable in view of the hilly nature of the course, the high average speed and the shunting time. It presents a strong argument in favour of using more powerful engines in vehicles of this capacity. A large engine has a further advantage in that it is rarely being overworked or even used at full throttle, so that its potential life, particularly between overhauls, is long. .

Having checked the fuel-consumption rate 1 then drove back to Scots Hill. Facing up the hill, the outfit was stopped on the steepest section, where the gradient is 1 in 7+. It was possible to hold the vehicle on this gradient by using either the prime-mover hand brake or the semi-trailer hand brake separately, and it was not necessary to apply the foot brake when pulling on either of the hand brakes.

An extremely smooth restart was then made in second gear, with complete absence of either clutch slip or transmission judder. So smooth was this start, indeed, that a Scammell representative, who was watching from outside, was convinced that I had used bottom gear. Full throttle was not necessary and there was no smoke present in the exhaust gases when pulling away. Several other restarts were made on this gradient with similar success.

A wide level stretch of the North Orbital Road, near Hatfield, was used for the braking and acceleration tests. The concrete road surface Was dry during the braking tests and emergency stops from 20 m.p.h. and 30 m.p.h. produced excellent and consistent figures. There was no wheel-locking, grabbing, or instability, nor even any brake squeal. The retardation rates from each stop were naticeably constant and devoid of surge.

From heavy marks in the road it was obvious that all the wheelswere just on the point of locking, which shows that the braking was at peak efficiency. The difference between the average deceleration rates, as shown by the stopping distances, and the maximum rates rec. orded by the Tapley meter was about 10 per cent., which will be accounted for by a slight delay in pressure build-up at the wheel cylinders.

Acceleration tests showed to the full the value of high power-to-weight ratio in a vehicle of this size. Top gear was used for the 10-30 m.p.h. runs, although this gear ratio is not 1 to 1. The outfit pulled away smoothly from 9 m.p.h., however, and the times were so good that I used this overdrive gear, rather than fifth. Third, fourth and fifth gears were engaged for the standingstart tests, quick changes being possible by making full use of the clutch stop.

Easy to Drive

Despite its size, the Scammell was simplicity itself to drive.' The seating position is comfortable and all the cogtrols are placed so as to reduce fatigue to a minimum. Excellent vision is afforded by the wide windscreen and promotes confidence in heavy traffic. The positive response of brakes and steering spell safety under all conditions, even on wet and greasy roads at high speeds.

Although the cab appointments are good, I would like to see more attention paid to ventilation. Clutch operation is through a straight mechanical linkage, but it is not heavy to use and even when double de-clutching, quick and Rertain gear changes can be made.

Maintenance of the outfit should be reasonably simple, despite its size; certainly there should be no trouble in attending to the engine. With the bonnet top and sides removed the power unit is fully exposed. The changes to the braking system have simplified adjustment and the exclusive use of rubber-bushed components reduces the amount of greasing necessary.