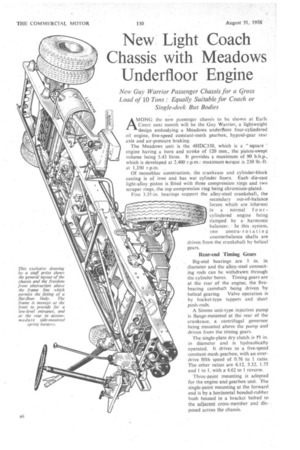

New Light Coach Chassis with Meadows Underfloor Engine

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

New Guy Warrior Passenger Chassis for a cross Load of 10 Tons .• Equally Suitable for Coach or Single-deck Bus Bodies

MONG the new passenger chassis to be shown at Earls Court next month will be the Guy Warrior, a lightweight design embodying a Meadows underfloor four-cylindered oil engine, five-speed constant-mesh gearbox, hypoid-gear rear axle and air-pressure braking. The Meadows unit is the 4HDC330, which is a "square ' engine having a bore and stroke of 120 mm., the piston-swept volume being 5.43 litres. It provides a maximum of 90 b.b.p., which is developed at 2,400 r.p.m.: maximum torque is 230 lb.-ft.

at 1,350 r.p.m. .

Of rnonobloc construction. the crankcase and cylinder-block casting is of iron and has wet cylinder liners. Each die-cast light-alloy piston is fitted with three compression rings and two• scraper rings, the top compression ring being chromium-plated.

Five 3.35-in, bearings support the alloy-steel crankshaft, the secondary out-Of-balance forces which are inherent in a normal f our cylindered engine being damped by a harmonic balancer. : In this system, two contra-rotating counterbalance shafts are driven from the crankshaft by helical ' gears.

Rear-end Timing Gears

Big-end bearings are 3 in. in diameter and the alloy-steel connecting rods can be withdrawn through the cylinder bores. Timing gears are at the rear of the engine, the five. hearing camshaft being driven 'by helical gearing. Valve operation is by bucket-type tappets and short push-rods.

A Simms unit-type injection pump is flange-mounted at the rear of the crankcase, a centrifugal governor being mounted above the pump and driven from the timing gears.

The single-plate dry clutch is r3 in. in diameter and is hydraulically operated. It drives to a five-speed constant-mesh gearbox, with an overdrive fifth speed of 0.76 to 1 ratio. The other ratios are 6.12, 3.32, 1.75 and 1 to 1, with a 4.62 to 1 reverse.

Three-point mounting is adopted for the engine and gearbox unit. The single-point mounting at the forward end is by a horizontal bonded-rubber bush housed in a bracket bolted to the adjacent cross-member and disposed across the chassis. A similar type of unit is used for :he two points at the rear, with the axes of the bushes parallel to the chassis centre-line. From the gearbox the drive is by a short singlepiece shaft having two needle-rollerbearing universal joints.

The hypoid crown wheel and pinion and differential gears are positively lubricated by means of a plunger pump driven by an eccentric from the drive-pinion nose. A wide range of rear-axle ratios is available, including assemblies giving 5.23, 5.68 and 6.5 to 1 reductions.

Bendix-Westinghouse dual airpressure braking is used. The Tu-Flo 500 water-cooled compressor is driven by a shaft and belts from the engine. The braking system includes a lightweight dual valve which consists of two Bendix-Westinghouse type-E brake valves arranged in a common housing.

Each valve is piped to a separate air reservoir and operated simultaneously through a balance beam by a fulcrum lever attached to the brake pedal. When the brake is applied, the force exerted on both valves is the same and the delivered air pressure from each is identical.

Air is piped from one valve to the rear brakes and from the other to the front units. If a pipe fractures, or part of the system fails, the other section is unaffected. The brake units are of the Girling cam-operated, heavy-duty, two-leading-shoe type.

All the brake drums are 151 in. in diameter, the front facings being 41 in. wide and those at the rear 7 in. wide. Total friction area is 678 sq. in. Moulded facings are used.

Overslung progressive semi-elliptic springs are fitted to both axles. Spring centres are 62 in. and spring width 3 in. The tension side and the edges of all the leaves are . shot-peened, which greatly increases their resistance to fatigue. Armstrong lever dampers are used at the front and rear.

Cam and double-roller steering gear is employed in conjunction with a 191-in. steering wheel. The turning circle is 63 ft. A 24-gal. fuel tank is suspended between outriggers carried on the near side.

The longitudinal members of the frame are flat, with the top edges ramped down forward of the front axle to provide for a low floor level at the body entrance. At the rear, the frame is inswept 7+ in., which facilitates the outboard mounting of the spring brackets.

Frame overhang at the rear ha'been curtailed, but adequate support for body overhang is provided for by outriggers. Main-frame pressings have a maximum section of 8,-1 in. by

3 in. and are Ain. thick. Full-depth channel-section cross-members brace the frame at the body-mounting points. High-tensile steel bolts fitted in reamed holes are used in assembly.

There are no projections above frame level, so that the full length of the -chassis becomes available for

passenger accommodation on an uninterrupted floor line.

A flat-tube stack radiator is mounted below frame level forward of the front axle. The 18-in. sixbladed fan is shrouded in a glass-fibre reinforced-plastic cowl, which. is bolted to the radiator. The fan is driven direct through 1 two-piece jackshaft extension from the front of the crankshaft. There is a supplementary header tank mounted on the. left of the chassis.

Tyre Equipment

The tyre size is 9.00-20 in., the front tyres being 12-ply and those on the twin rear wheels, 10-ply. Lighting and starting equipment is 24v. The 94-amp.-hr. batteries—four 6v. units—are carried in a cradle mounted just forward of the rear axle.

The C.A.V. dynamo is cradlemounted on a chassis cross-member and is driven at engine speed by belts

from the same shaft that drives. the compressor and fan. Tts cutting-in

speed is 600 r.p.m., and its maximum output is 38 amp. The C.A.V. starter motor is of the axial pattern.

Independent grease nipples of the hook-on type are provided, but automatic chassis lubrication can be provided as an alternative.

Chassis weight distribution is: Front axle, I ton 16 cwt.; rear axle, I ton 17 cwt. Maximum gross vehicle weight is 10 tons.