For DRIVERS, MECHANICS & FOREMEN.

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS is paid to the sender of any letter which we publish on this page, and an EXTRA FIVE SHILLINGS to the sender of the one which we select as being the best each week. All notes are edited before being published. Mention your employer's name, in confidence, as evidence of good faith.' Address, .D., M. and F., "Ms Commercial Motor," 7-16, Rosebery Avenue, Landon, E.C. I.

Lamps Alight.

On Saturday, September 4th, light your lamps at 8.9 in London, 8.29 in Edinburgh, 8.20 in Newcastle, 8.24 in Liverpool, 8:17 in Birmingham, 8.19 in Bristol, and 9.7 in Dublin.

A Home-made Clutch Stop

The sender of the following communication has been awarded the extra payment of os. this week.

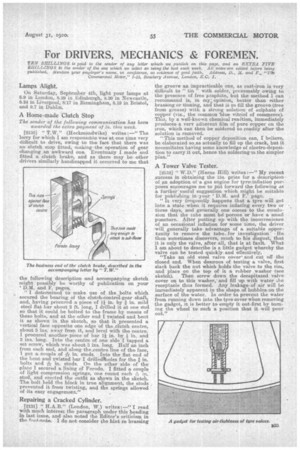

[2130] " T.W." (Heckmondwike) writes :—" The lorry for which I am responsible was at one time very difficult to drive, owing to the fact that there was no clutch stop fitted, making the operation of gear changing an awkward one. Eventually I made and fitted a clutch brake, and as there may be other drivers similarly handicapped it occurred to me that the following description and accompanying sketch. might possibly be worthy of publication on your D.111. and F. pages.

"I determined to make use of the bolts which secured the bearing, of the clutch-contra-gear shaft, and, having procured a piece of l in. by I in. mild steel flat bar about 2 ft. long, I drilled it at one end so that it could be bolted to the frame by means of these bolts, and at the other end I twisted and bent it as shown in the sketch, so that it presented a vertical face opposite one edge of the clutch centre, about 3 ins, away fmra it, and level with the centre. I procured another piece of bar 1 in. by in. and 3 ins. long. Into the centre of one side I tapped a set screw, which was about 3 ins. long. Half an inch from each end, and along the...centre line of the face,

put a couple of Fe, in. studs. Into the flat end of the bent and twisted bar I drilledtholes for the _a in. bolts and Ar. in. studs. On the other side of the plate I secured a lining of Ferodo. I fitted a couple of light compression springs, one round each -& in, stud, and erected the outfit as shown in the sketch. The bolt held the block in true alignment, the studs prevented it from twisting, and the springs allowed of its easy engagement"

Repairing a Cracked Cylinder.

[2131] " H.A.B." (London, W.) writes :—" I read with much interest the paragraph under this heading in last issue, and also noted the Editor's criticism in the fent-note. I do not consider the hint re brassing the groove an impracticable one, as cast-iron is very difficult to " tin with solder, presumably owing to the presence of free graphite, but the method I can recommend is, in my..; opinion, bettor than either brassing or tinning, and that is to fill the groove (free from grease) with a strong solution, of sulphate of copper (viz., the common 'blue vitriol of commerce). This, by a well-known chemical rea8tion, immediately produces-a very adherent film of pure copper on the iron, which can then be soldered to readily after the

solution is removed. .

"This method of copper deposition can, I believe, be. elaborated soas actually to fill up the crack, but it necessitates 'having some knowledge of electro-deposition to carry it out, hence the solderinges.the simpler plan."

A Tower Valve Tester. •

[2132] " W.D." (Herne Hill) writes:—" My recent success in obtaining the I5s. prize for a deseription of an adoption of 'a gas engine for tyminflation purposes encourages me to put forward the following as a further" useful suggestion which, might be suitable for publishing in.,your D.M. and F. page. "It very frequently happens that. a tyre will get into a, state when it requires inflating every two or three days, and generally one comes to the conclusion that the tube must be porous or have a small puncture. After putting up with the inconvenience of an occasional inflation for some time, the driver will generally take advantage of a suitable opportunity to remove the tube, for investigation He then sometimes discovers, much to his disgust, that it is only the valve, after all, that is at fault. What I am about to describe is a little gadget whereby the valve can be tested quickly. and effectively.

"Take an old steel valve cover' and cut off the closed end. When desirous of testing -a valve, first slack back the nut which holds the valve to the rim, and place on the top of it a rubber washer (see sketch). Then screw down the decapitated valve cover on to this washer, and fill np with water Utte receptacle thus formed. Any leakage-of air will be immediately apparent in the shape of bubbles' on the surface of the water. In order to prevent the water from mining down into the tyre cover when removing the gadget, tt is better to empty it out-first by turning the wheel to, such a position that it will pour out."