A NEW DESIGN OF REAR AXLE.

Page 15

If you've noticed an error in this article please click here to report it so we can fix it.

EAR AXLE 001iSTRUCTION has always been. a leading subject for discussion amongst both experts and laymen of the automobile world. Touring car chassis, and also those of commercial' vehicles, have, in respect of the construction of -this important unit, passed through the same phases. .commencing with a, chain-driven dead axle, and passing to the live axle in its several forms.

The construction of thelatter type units has always -afforded matter for debate, and -although there are still diverse opinions in force as regards the relative merits of the various designs on the market, the consensus of opinion is largely in_ favour of the fullfloating type of axle with the weight-carrying portion made of forged steel. There are still two main obstacles in the way of the general adoption of this type—the expense, and the diffiCulty of Obtaining supplies of the forgings or stampings. Where. the Quantities to" be dealt with are small, the expense of obtaining the requisite dies, etc., is almost prohibitive. When the productive capacity of the works in general is more promising, it is frequently found that the impossibility of obtaining supplies of stampings to keep up with the demand is the real obstacle in the way of maintaining the standard of-output which has been projected.

Both Of these difficulties have been successfully overcome by a design of axle which has been patented by W. Halcot lfingston,

M.I.A.E., A.M.I.C.E., and which, we understand, ,,is to be handled commercially by Messrs. Products and Equipments. Ltd., 125, Lower Thames Street, E.C..3. The axle is constructed -of ordinary standard rolled steel channels, which may be obtained in any quantity from a largo number of different concerns to standard sizes and specifications both as regards material and strength.

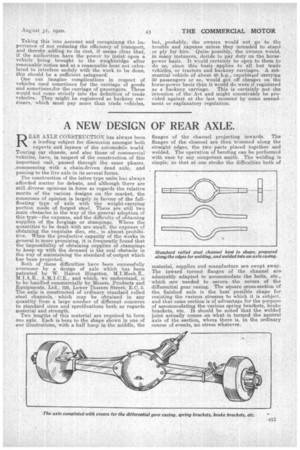

Two lengths-of this material are required to form one axle. Each is bent to the shape shown in one of our illustrations, with -a half hoop in the middle, the

flanges of the channel projecting inwards. The flanges of the channel are then trimmed along the straight .edges, the two parts pla,ced together and welded. The operation of bending can be performed with ease by any competent smith. The welding is simple, so that at one stroke the difficulties both of material, supplies and manufacture are swept away. The inward turned flanges of the channel are admirably adapted to accommodate the bolts, etc., which are needed to secure the covers of the differential gear casing. The square cross-section of the finished axle is the best' possible shape for resisting the various stresses to which it is subject, and that same section is of advantage for the purpose of accommodating the various spring brackets, brake brackets, etc. It should be noted that the welded joint actually comes on what is termed the neutral axis of the section, where there is, in the ordinary course of events, no stress whatever.