A Popular American Dry-plate Clutch.

Page 16

If you've noticed an error in this article please click here to report it so we can fix it.

For many years, both in this country and America, the leather-covered cone clutch and the metal-tometal " plate " clutch working in oil have pretty well divided the patronage of the public. Neither has shown so many good points as to oust the other from the field, and hence both may be considered open to improvement. Some few makers have used single plate clutches, working face to face, dry, like the De Dion and the old Lotis types, and now, in America, another type is disputing the market with the others.

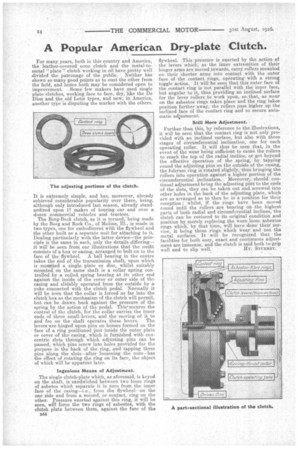

It is extremely simple, and has, moreover, already achieved considerable popularity over there, being, although only introduced last season, already standardized upon 17 makes of touring car and over a dozen commercial vehicles and tractors.

The Borg-Beck clutch, as it is termed;being made by the Borg and Beck Co., of Moline, Ill., is made in two types, one for embodiment with the flywheel and the other built as a separate unit for attaching to it. Dealing particularly with the latter device—the principle is the same in each, only the details differing— it will be seen from our illustrations that the outfit consists of a box or casing, arranged to bolt on to the face of the flywheel. A ball bearing in the centre takes the end of the transmission shaft, upon which is moinated a single plate or disc, whilst suitably mounted On the same shaft is a c011ar spring controlled by a coiled, spring bearing at its other end against the inside of the cover or outer side of the casing and slklably operated from the outside by a yoke connected with the clutch pedal. Normally it will be seen that the collar is forced as far into the clutch box .as the mechanism of the clutch will permit, but can be drawn back against the pressure of the spring by the action of the pedal. This secures the control of the clutch, for the collar carries the inner ends of three small levers, and the moving of it to

and fro on the shaft operates these levers. The levers arc hinged upon pins on bosses formed on the face of a ring positioned just inside the outer plate or cover of the casing, which is furnished with concentric slots through which adjusting pins can be passed, which pins screw into holes provided for the purpose in the back of the ring, and tapping these pins along the slots—after loosening the nuts—has the effect of rotating the ring on its face, the object of which will be apparent later.

Ingenious Means of Adjustment.

The single clutch-plate which, as aforesaid, is keyed on the shaft, is-sandwiched 'between two loose rings of asbetos which separate it in turn from the inner face of the casing—i.e., from the flywheel—on the one side and from a second, or contact, ring on the other. Pressure exerted against this ring, it will be seen, will force the two rings of asbestos, with the clutch plate between them, against the face of the

B44 flywheel. This pressure is exerted by the _action of the levers which, as the inner extremities of their longer arms are moved inwards, carry rollers mounted on their shorter arms into contact with the outer face of the contact rings, operating with a strong toggle action. It will be seen that this outer face of the contact ring is not parallel with the inner face, but angular to it, thus providing an inclined surface for the lever rollers to work upon, so that, as wear on the asbestos rings takes place and the ring takes position further away, the rollers pass higher up the inclined face of the confect ring and so secure automatic adiustment Still More Adjustment.

Further than this, by reference to the illustrations, it will be seen that the contact ring is not only provided with an inclined surface, but also with three stages of circumferential inclination, one for each operating roller. It will thus be seen that, in the event of the wear being sufficient to cause the rollers to reach the top of the radial incline, or get beyond the effective operation of the spring,. by tipping round the adjusting pins on the outside of the casing, the fulcrum ring is rotated slightly, thus bringing the rollers into operation against a higher portion of the circumferential inclination. Moreover,, should continual adjustment bring the adjusting pins to the ends of the slots, they can be taken out and screwed into i other holes n the back of the adjusting plate, which are so arranged as to then be in a position for their reception ; whilst, if the rings have been moved round until the rollers are bearing on the highest parts of both radial and circumferential inclines, the clutch can be restored to its original condition and position by merely replacing the worn loose asbestos rings which; by that time, will have done their service, it being these rings which vear and not the metal surfaces. It will be recognized that the facilities for both easy, exact and continuous adjustment are immense, and the clutch is said both to grip

well and to slip well. HY. STURIKEY.