Competition Brings Quality

Page 114

Page 115

Page 116

Page 117

Page 118

If you've noticed an error in this article please click here to report it so we can fix it.

['TALKING around Earls Court after V V spending the weeks before the opening Ting to evaluate the standards of the equiplent that trailer making companies were oing to exhibit has shown me one thing more 'early than any other. Although in my preiew report (COMMERCIAL MOTOR, Septemer 16) I said there would be nothing very utstanding and that there was a noticeable aunt to simplicity in design, the one thing riat I had not bargained for was the high egree of product quality that would be hown by almost every maker.

The forecast of a return to simplicity, I till feel, was fair comment and it is indeed Loticeable that a great majority of semirailers are equipped with Rubery Owen xles at least, if not with complete running ;ears of that make. Even when one can find chides without that company's axles it is iot unusual to find that the hubs and brake ear are of that make. There are, as I wrote in last week's issue, not many air suspensions on show, but those that do appear are well put together and are probably the best of those we have seen in the past. Among the special semi-trailers exhibited are a couple of vehicles designed to meet the needs of the fast growing containerized freight traffic, those on the stands of Taskers of Andover and R. Murfitt being of particular interest to operators thinking of engaging in road/rail co-operation. Among the other trailers that stand out in large numbers at the Show are the bulk vehicles which have been built for the carriage of almost every type of commodity one can think of. There are great gaggles of tankers for all purposes alongside many vehicles designed for the carriage of powders and granular material, each mounted upon a running gear unit, with the beam strength of the trailer derived from its bodywork.

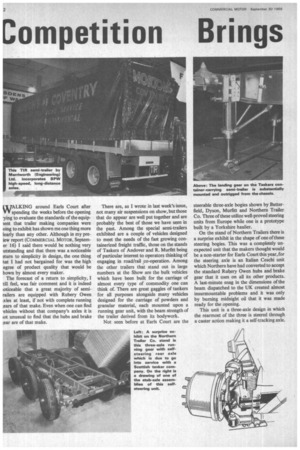

Not seen before at Earls Court are the steerable three-axle bogies shown by Butterfield, Dyson, Murfitt and Northern Trailer Co. Three of these utilize well-proved steering units from Europe while one is a prototype built by a Yorkshire haulier.

On the stand of Northern Trailers there is a surprise exhibit in the shape of one of these steering bogies. This was a completely unexpected unit that the makers thought would be a non-starter for Earls Court this year, for the steering axle is an Italian Ceschi unit which Northern have had converted to accept the standard Rubery Owen hubs and brake gear that it uses on all its other products. A last-minute snag in the dimensions of the beam dispatched to the UK created almost insurmountable problems and it was only by burning midnight oil that it was made ready for the opening.

This unit is a three-axle design in which the rearmost of the three is steered through a caster action making it a self-tracking axle. The axle is a box-section fabrication and it carries the king-pins in standard-type eyes that are swept forward of the axle centre to provide the required caster. Hydraulic dampers are fitted between the frame and the steering arms to prevent flutter when the vehicle is travelling at high speeds.

On the stand of R. A. Dyson and Co. Ltd. is shown the Viberti-axled three-axle trailer that was tested and described in COMMERCIAL MOTOR on September 2. This vehicle is equipped with air suspension and loadsensed brakes.

The only other of the four steering bogies that can be said to be in full production is the Murfitt-Schmidt unit shown fitted to the Murfitt moving-bulkhead vehicle. This is a German running gear in Which all the axles have steering effect, achieved via a system of linkages connected to, and through, the bogie sub-frame. This machine, like the other steering types has the effect of reducing the inner swept circles on which the vehicle travels when turning a corner, thus providing for considerably greater manoeuvrability.

Designed and built by Yorkshire haulier Richard Petty—with a lot of assistance from W. P. Butterfield (Engineers) Ltd.—the prototype gear mentioned was described in COMMERCIAL MOTOR on September 2, when there was also a report of the handling characteristics. This unit is exhibited on the demonstration park where interested parties can see it in operation.

Towering above almost every other exhibit in Earls Court this year are the big-tipper brigade. Examples of these vehicles can be seen on the stands of York Trailers, Crane Fruehauf, Neville, Northern Trailer Co., and Welford Engineering among others, while Highway-Hoynor and Hands Hi-spill are among examples in the demonstration park. In each case there are different characteristics to be seen in each job. 0 the Northern and Neville stands there ai types using the Villiers system of tippin about the rearmost axle while, on the °the three in the *exhibition building, the unii are of conventional construction embodyin a chassis frame with superimposed bodyworl Aluminium plays a big part in the construe tion of bodies for most of these vehicle but in my opinion probably the best exampl of what can be done with light alloy is the un shown on the Crane Fruehauf stand. Thi vehicle has a 33 cu. yd. tipping body lifte by a single five-extension ram situated a the front of the chassis frame. The body i U-shaped, having all the internal corner radiused to facilitate clean tipping. Runnin gear is Crane Fruehauf F2 type employin, slipper-ended springs and having the axle located by radius rods.

The battle of scrub versus payload in th tandemand three-axle trailers for operatio at 32 tons has produced one unusual mock on the stand of Multiwheelers Ltd. Thi company has not plumped for the complica tions of a steering bogie in order to lower th. tyre scrub on its three-axle semi-trailer instead an ingenious method has been devised. By the use of balance beams of unequal length a differential loading of the centre and outer axles has been achieved, together, the makers say, with scrub that is equivalent only to that developed by a normal tandem-axle trailer. This vehicle is going into service with Entress Transport, of Swansea, where such a unit has been on approval trials for some time.

Three decker

Carrimore Six Wheelers show the latest development in their range of car transporters. This vehicle is a tri-decked unit capable, the makers say, of carrying nine small cars. It is equipped with a new design of running gear embodying inverted trunnion-mounted leaf springs with the axles slung on either end and located via torque rods to the centre of the thumion. These rods serve as non-reaction rods and obviate axle hop when braking. Girling brakes are powered through triplediaphragm chambers and the two upper decks are raised and lowered by hydraulic rams. The power for these is provided on the Show vehicle by a small donkey-engined hydraulic pump mounted on the nearside of the trailer. The centre deck of the unit is adjustable to accommodate cars of different heights and the front end of this deck is also raised and lowered hydraulically. Unfortunate circumstances prevented one of the exhibits on the stand of R. Murfitt Ltd. from appearing in the form that it should be. Failure of the correct running gear to arrive in time made it necessary to show it with gear that destroys an important feature of the design, that of a low loading height. The proper running gear gives the vehicle (a containercarrying and transferring unit) a loading height of only 3 ft. 2 in. but the gear fitted makes it considerably higher than that, giving the impression of an unwieldy monster. This vehicle is designed to transfer containers from rail wagons to itself or vice versa, and for this purpose it is equipped with built-in hydraulic lifting gear which permits the trailer to be raised and lowered on a level plane. Also running from the hydraulics are two winches that operate cables linked to the transfer dogs. These are extended beneath the container and then reversed, pulling the container off the rail wagon towards the road trailer. They only travel half the width of the trailer, so that when the container is half on, the dogs are returned to the extended position where they engage with a second row of catches. With the movement completed, the container is positioned on the trailer, permitting it to he carried away. The same system in reverse is used to offload the container.

A new running gear is shown by York Trailer Co. This again was a surprise exhibit of which there had been no knowledge prior to the opening of the Show. By utilizing the now readily available low-profile tyres, York have produced a gear incorporating widespread spring centres. This of course has the effect of reducing roll on corners, but more important—from the tanker operator's point of view—it allows the centre of gravity to be lowered a good deal as the radius of the tank can be sunk into the increased space between the two main members. Also on the York stand is a Teamster semi-trailer with a sliding bogie which allows both the outer axle spread and the axle loadings to be altered at will to accommodate varying requirements of long loads.

Another new running gear is shown by

Pitt Trailers. This is a very simple unit, like many others at this Show, but looking a bit closer into it one sees that a deal of thought has been put into its design. A problem that has always been present in slipper-ended suspensions is the fact that when load is imposed upon the gear the radius rods move in an arc about their fixed axis. Where only lower rods are fitted the axles move backwards slightly to accommodate this movement but where there are radius rods both above and below the axle, the spring tips up, increasing the load on the end farthest away from the radius-rod anchor. To overcome this Uneven loading of the road springs Pitt have built into the spring saddles a steelbacked rubber bush which allows the axle to turn in the saddle as the spring deflects. Thus the loading on the slipper ends of the spring remains constant and equal. This system is claimed to be a very simple and effective answer to bogie hop when braking.

Lightweight van Looking at the semi-trailer vans in the Show there is one that takes my eye for more reasons than one. This is the Hands-Bonallack Weightsaver shown by Hands (Letchworth) Ltd. I particularly like the method of building the running gear framework on to the frame of the body. The substantial boxmembers are swept up at an angle from the running gear members to lie flush with the top and bottom of the side rave member. Six in number, they are fabricated from sheet steel in. thick and although they are open to atmosphere to allow them to breathe, the aperture is satisfactorily closed, from the security aspect, when the vehicle is operated on TIR work. This vehicle is equipped with Hands RTS 500 non-reactive suspension and this in turn is fitted with the new Hands oilfilled hub. It is one of the many trailers shown mounted on Michelin tubeless tyres. Although the construction of this unit is substantial from all points of view, the makers have succeeded in getting the unladen weight down to a very respectable level. Plated for 30 tons g.t.w., having 16.5 in. by 7 in. three lineoperated air brakes incorporating a "blowdown" to allow quick release of the third-line system, and being 28 ft. in overall length, this trailer scales only 4 tons 2 cwt. 1 qr.

The big tipper from the Hands organization is a compromise between the system of tipping round the rear axles and a trailer having a rigid chassis. On this machine there is a short chassis and stabilizing framework between it and the fifth-wheel which also carries the single-ram tipping gear. When the body is tipped the whole of the rear bogie stays on the ground but, as in those vehicles having no hinge between the body and the running gear, the effective wheelbase of the trailer is shortened. This vehicle is shown on the demonstration park.

Load-sensed brakes Moving to the Brockhouse stand, here one finds a new running gear having non-reactive characteristics. This is yet another unit of which there was no hint before the Show. This gear is equipped with a load-sensed braking and the bogie incorporates a system of linked balance-beam halves to produce its non-reactive qualities. A link is carried from the rear of the rearmost spring to the rear of the beam between the two axles. The reaction rod is carried diagonally from the upper side of the rear spring to the lower side of the beam and thus the reaction is cancelled out.

Heavier landing gears are to be seen on almost all the semi-trailers exhibited. The new Davis Magnet gear is shown on most of them, but the two-speed Adrolic is also in the picture in no mean quantity. On the Multiwheeler stand the three-axle trailer mentioned earlier is equipped with an American air-powered hydraulic landing-gear which is connected into the braking pressure system. Each movement of the operating lever causes one movement of the gear and when the tractive unit is uncoupled the landing gear is rendered inoperative. Many of the landing gears shown are much more substantially braced than those seen in previous Shows. This is obviously a lesson that has been learned and remembered and one to which I wholeheartedly subscribe.

Machinery carriers are not in very great evidence this year but two that are shown on the stands of Dyson and Taskers reflect the trend towards high-quality equipment. The Dyson has been built for British Ropes Ltd. and will be used for carrying coils of wire rope. The bed of this unit is completely removable from both the neck section and the running gear and when in service it is left in the winding sheds with a drum ready mounted, and the ropes are wound with this in situ Standard machinery carrier On the other hand the Taskers low-loader is one of that company's well known Little Giant standard production types which operators can usually purchase off the shelf. This vehicle is plated for operation at 22 tons g.t.w. and once again there is a high degree of quality about it.

Several refrigerated semis are shown, one of particular interest on the stand of Crane Fruehauf. This is a Vanguard frameless van which has been produced for the fleet of Union Cartage Ltd. and the main interest lies in its ability to support 20 tons of meat hanging from the roof which is—like the ordinary van models—of one-piece construction. The front bulkhead of this van is reinforced to carry a Thermo-King Calor Gas driven refrigeration unit and the unit is mounted on standard Crane Fruehauf F2 running gear.

A semi-trailer not seen before at Earls Court is the one produced by Road Transport Services Ltd., of Hackney, London. This vehicle comprises a main-frame assembly built by the exhibitors mounted on Dyson DNR suspension. Bodywork is refrigerated by a Thermo-King unit and the body has a clear interior length of 29 ft. 2 in. and it is 6 ft. Ii in. wide by 8 ft. 8 in. high.

Another first-timer at Earls Court is shown by a company previously engaged in the manufacture of caravan trailer chassis. This company, Peak Trailer and Chassis, of Stockport, has come up with a very nicely constructed unit which embodies some unusual details. One of these is the use of boxsection front and rear cross-members and another is the method of directing the run of the cable connected to the Neate ratchet handbrake lever. One often sees the cable from this unit running away at an oblique angle to the winding drum or alternatively running through a tube which after a few months in service inevitably frays the cable. Peak have mounted a small jockey-wheel on a square tube and by rotating the tube to the various angles required to align the wheel and the anchor point, the cable is assured a free-running long life.

Old stager About the only running gear that was shown at the Commercial Motor Show of 1933 that is shown again this year—and, in fact, has been present at every Show in between—is the BTC Four-in-Line. This year the unit is shown with automatic lubrication, which derives its operating power from the deflection of the road springs. Also shown on the British Trailer Co. stand is a 14-ton machinery carrier and, like other vehicles of this class, quality of construction is a noticeable characteristic. The loading ramps and jacks shown at Earls Court are standard equipment.

TIR semi-trailers are shown on stands of almost all the trailer makers. This very popular class is now approaching the stage where the removable bodywork is often quantity-produced. The TIR model shown by Roden Trailers, for instance, shows what can be done with TIR bodywork which it is claimed is completely interchangeable between any vehicles of this type made by the company.

On the Boden stand the new Mk. III chassis announced recently shows many details of constructional design based on experience of semi-trailer operation and I particularly liked the "tying in" of the main tubular cross-members to the webs of the main frames. Torsional stresses apparent when a vehicle is cornering fast with high loads are accommodated through these cross-members and much of the local stressing which is applied to the main frame via the running gear mountings is dispersed through secondary reinforcing pads between the running gear and the main-frame flanges.

The new range of Scammell trailers bearing the name Challenger shows a different method of mounting the suspension. Front spring eyes are connected to the chassis frame with a shackle pin whilst the rear end of each spring bears on a cam-shaped slipper • end, so providing progressive suspension under different conditions of load. Like most other units in the Show the main frames are of I-beam construction with cross bearers pierced through and welded on the vertical runs only. These are arranged to carry floor-boarding the top level of which is flush with the top flange of the main frames.

Among the smaller trailer makers, outstanding examples of unusual vehicles are shown by Scottish Aviation Ltd. and Scottont Ltd. On the Scottish Aviation stand, two examples of the Minatic can be seen and on the Scottorn stand there is a low-loading semi-trailer giving an uninterrupted floor area with no wheelboxes. This vehicle is fitted with an automatic coupling but a fifthwheel type is optional. Also seen on this stand is a flat-topped tanker drawbar trailer which can be used for carrying bulk liquids or dry cargoes.