REGIONAL SPOTLIGHT NORTRAST

Page 30

Page 31

Page 32

Page 34

Page 35

Page 36

Page 37

If you've noticed an error in this article please click here to report it so we can fix it.

The great industries associated with the North-East—coal, steel and shipbuilding—have largely perished but there has been a gradual revival in the region's fortunes as new industries have taken their place. Patric Cunnane braved the fog on the Tyne to find out how hauliers have coped with a changing industrial base. He met a quarryman who not only supplies roadstone but recycles the waste; a roofing expert whose trucks win show prizes; a tipperman who is shoring up the coast; a general haulier who has moved from railway arches to soft sofas; an operator who keeps Britain in crunchy snacks—and another who FACTFILE: JOHN WADE (HAULAGE) BASFD Ayecliffe Village, near Darlington. FOUNL 1966 by John Wade. CONTACT: John Wade, managing director; Tony Gray, sales manager; Bruce Whitley, operations manager. " 60 vehicles including 48 six and eight-wheel tippers (of which 35 are Hinos), six skip lorries and six tractive units. Other marques include Scania, Iveco and Renault. Buys new. Most recent purchase was a Scania 143, in April 1997. SPECIALITY CONTRACT: Supplying roadstone to the construction industry. RJRNOV £9m.

JOHN WADE (HAULAGE) WHEN CM VISITED John Wade's Ayecliffe quarry, the man who began the business 31 years ago was having a day off. He was indulging in his favourite hobby, a string of prize racehorses. All bets were on, however, as his three lieutenants took CM on a guided tour of the £9m quarry-based business which combines haulage, body building, plant hire, a Hino dealership, roadstone quarrying, aggregates supply, waste recycling and a landfill site. Sales manager Tony Gray was joined by operations manager Bruce Whitley and maintenance manager David James to guide us through the company's history.

"John Wade started in 1966 with an old digger doing demolition and site clearance," says Gray. "He expanded into running wagons and bought the quarry in 1971." A second quarry was purchased 15 years ago; the water pumped out and quarrying restarted. That quarry is worked out and has become a landfill site, which is now nearly full.

The company has a second landfill in its main example, can fetch a premium price from golf courses, and a lot of construction waste can be recycled for roadfill.

What makes the haulage side of the business different from that of most British operators is its adherence to Hino; the Japanese lorry assembled in Ireland.

Most of the vehicles bought by the in-house Hino dealership go into Wade's own fleet. Of 48 tippers, 35 are Hino and, as maintenance manager David James says, even that isn't enough. Supply difficulties have limited the vehicles' dominance: "If we could have got all Hinos we wouldn't have a mixed fleet," he says. "They are a good robust tipper." Operations manager Bruce Whitley adds that the universality of many components is a big advantage on parts storage, with spring pins and brake shoes interchangeable between six and eight-wheelers: "It's the biggest port of the fleet yet Hino components take up less room than all the others," he remarks.

At the core of Wade's business is its quarrying operation, providing limestone and other materials to the civil engineering industry and local authorities. "We're doing a big contract on the Al 9 which is converting from two to three passing set-up it's a lucrative job, delivering roadstone and backloading waste for recycling and landfill.

The landfill tax has wrought changes in the construction industry, adds Gray. Builders try to recycle waste on site for filling purposes rather than have it taken away. It's also in Wade's interest to recycle as much waste as possible. The most damaging waste is taxed at £7 a tonne if it goes into landfill and is known as "active". It includes anything that rots and produces gases, such as wood, paper, plasterboard and plastics. Inert waste, such as concrete, brick and subsoil is charged at £2 a tonne. "A full load at £7 a tonne pays £140 tax," says Gray, "We try to convert what goes into landfill to £2 a tonne." There's a £5 margin there but it's not cost free: separation screens, stone crushers and a transfer station have required serious investment. "But if we don't do that, we simply put everything in the tip and pay the taxman," says Whitley.

CM is taken down to the quarry floor, 100 feet or so below the main road, to photograph the operation quarrying the best grade limestone found at the lower levels. Here, three Nordberg stone crushers on caterpillar tracks

Instead, tippers can load directly from the quarry floor, filled by Komatsu shovels (five in the fleet at £140,000 each) which weigh exactly the right amount, into the trailer. A powerful water pump drains excess water into a river above the site.

The Wade empire also encompasses farming: when the landfill areas are full, the topsoil is replenished and farming starts again within Iwo to three years.

There's also a contract with RMC to provide seven vehicles in its colours driven by Wade drivers and working out of mortar plants in Peteriee and Newcastle.

In addition, Wade provides a steady flow of work for subcontractors. "A lot is day to day," Whitley explains. "The A19 builders send us a fax projecting the week's work, but by Tuesday it's all changed. Either the weather's picked up or they've decided to do a longer stretch."

Tony Gray nods in agreement. "We never know what we're doing till about 4pm the night before," he says. Poor weather slows demand: "No one wants stone if there's six feet of snow," says Whitley. Even then, Wade's crushers keep working, producing stock for the inevitable surge that follows the thaw. Tour over, we stand in the bodyshop, watching paint dry on a tipper body built there. Whitley shrugs, "If we're guilty of one thing, it's trying to do too much!"

RANK HUDSON TRANSPORT

FRANK HUDSON HAS THE AIR of a showman about him. For a start, he's a regular entrant at Truckfest—his Mercedes 1850, bearing the legend Big Hud, was highly commended at this year's event.

Alongside this beauty the punters would have come across a customised Reliant Robin pickup, lovingly put together by Hudson's fitter, Les Johnson. The pickup sees service giving festival rides to the kids. Then there are details like the Frank Hudson-labelled wine and the Frank Hudson mugs which keep his name in front of his customers. Finally, there is Frank himself; dapper in an Ach-os bomber jacket, wrists heavy with gold bracelets, and unbridled enthusiasm spilling over into his approach to the job. "I went to see my bank manager and came out proud as punch. He asked, 'How come your business is going up when all the other transport companies are going down?' I said it's because I don't do nothing for nothing." Besides Hudson, the key people in this 15-truck business, which specialises in carrying roofing sheets and car parts, are his wife Ann (accounts and office management) and traffic manager Geoff West. What exactly does Hudson do? "I have a bit of a drive," he says. "I can't just sit in an office all day!" So he frequently takes a van out for a local delivery just to burn up some of that adrenalin. He began in a small way ("with a Leyland Boxer—load of crap") 24 years ago, delivering sheets of asbestos roofing. Today the tainted asbestos has gone but he counts several roofing firms among his clients, in particular CA Roofing Services in nearby Bishop Auckland for which he runs five dedicated units.

The deliveries are often to building sites and the key to success, says Hudson, is to never say no when a customer demands goods at a moment's notice: "Gangs in London work all weekend," he says. "If they ring up and say 'send more roofing', I say `no problem'. You can't refuse anything in this job. If you do, they don't come back and someone else gets it." He rubs his hands: "All these Saturday nights add up. It could be -£3,000 extra on our bill to the customer at the end of the month."

Car parts have a similar urgency. Hudson's artic collects from lixal factories for delivery into assembly plants, including Rover in the Midlands. A local haulier, Dunns of Shilclon, subs work to Hudson, which could involve collecting seatbelts from Peterlee and delivering to Birmingham for trans-shipment to Germany. Then there are hotshot runs in the smaller vehicles, where the transport costs are disproportionate to the value of the goods: "I've seen them go to Germany with a box that size," says Hudson, spreading his hands. He cheerfully admits he makes "plenty of money", helped by his largest customer, CA Roofing, which settles invoices in 30 days. "A local firm ran 30 tippers and went bust," he recounts, "That tipper job is not worth a light. I got more money for 7.5 tonnes than he was getting for 23 tonnes." Fortunately, his tipping pal is now trading again— and Frank Hudson's workshop does his maintenance.

Hudson is a stickler for keeping the wagons clean. They're washed so regularly that the waterboard, puzzled by his MO water bill, suggested that he might have a burst pipe! Drivers have to pay for any damage that is their fault with money stopped out of their wages. This may seem harsh, but Hudson maintains that it focuses drivers' minds on avoiding gateposts. At least one of his drivers shares his obsession for cleanliness. Geoff Plews, who drives the award-winning Mercedes 1850 (pictured), regularly stops all night in the yard to clean the vehicle before finishing his week's shift. There's dedication for you.

FACTFILE: FRANK HUDSON TRANSPORT BASED: West Auckland, Co Durham. FOUNDED: 1973. CONTACT: Frank Hudson, managing director. FLEET: 15 vehicles including Mercedes 1850 artic unit; Mercedes 7.5 tonner; 17 tonne MAN flat; Scania 6-wheeler; 3x17 tonne Scania, two Mercedes pickups. Usually buys new. Most recent purchase MAN 17 tonner, October 1997. SPECIALTY CONTRACT: Delivery of roofing materials to construction industry. TURNOVER: Elm.

GURTEEN

AS THE 20TH CENTURY nears its end there are disturbing signs: the effects of global warming on the planet are beginning to materialise as bizarre weather conditions and environmentalists are being proved right in many of their predictions.

For operators like Gurteens at Houghton-Le-Spring, environmental awareness is proving good for business. The company operates a wastetransfer station and hires out around 4,000 skips to the public.

For some time the hirers have been obliged to pay landfill taxecollected by Gurteens: "We are unpaid tax collectors," says fleet director Andrew Gurteen, "but turnover has rocketed because we only have to pay the tax each quarter."

And, as Gurteen points out, as long as the public has waste, the company will have a job to do. A continuous flow of skip lorries arrive at the depot to empty the skips in the transfer station where tippers wait to transfer bulkloads to local landfill sites. All well and good, but, there is a looming problem of capacity.

Gurteens delivers to sites within about a 50 mile radius of its Tyne & Wear base: "There are enough landfills for the next five to 10 years," says Andrew Gurteen, "but when they're full we'll need to travel further afield to the Midlands. Then we will have to go into ejection trailers designed to carry waste a greater distance."

In addition to its waste-transfer work the company runs 15 powder tankers and seven steel-bodied scow-end trailers, designed for the heavy end of construction haulage.The scow-ends have no tailboards and are at work on a project to prevent coastal erosion at Hartlepool: "They carry rocks weighing up to four tonnes, as big as a Mini Metro, three or four at a time," Gurteen explains.

The company diversified into selfdrive hire after spotting a gap in the local market when a local maintenance workshop was unable to return vehicles to customers as quickly as demanded. Many of Gur teens' own vehi des are on a three-year contract maintenance deal with Union Trucks, its local Scania dealer. The service has proved so satisfactory to Gurteens, with a reliable 24-hour servicing arrangement, that the company is increasingly moving to Scania from the Volvos which at one time comprised 100% of its fleet. It claims to be the first operator in the UK to run the Four Series eight-wheeler.

Before leaving, CMspends a few minutes watching a big CAT shovel loading the tippers, clawing at the mountain of binliners and cardboard boxes piling up to the back of the transfer bay. As the rubbish crunches into the back of the bulkers, Gurteen ponders over the state of the economy in the North-East.

There have been no fireworks, but then again, he says: "It's stayed steady here. The boom has yet to come." FACTFILE: RAMAGE TRANSPORT BASED: Long Benton, Newcastle with 4,650m2 of warehousing. FOUNDED: 1975 (switched from coal deliveries to general haulage). CONTACT: Robin Ramage, managing director. FLEET: 85 vehicles, mostly Leyland Daf and Iveco Ford. Buys new; most recent purchase was three EuroTech 6x2s MP400s and a Mercedes-Benz Actros 2535 in October 1997. SPECIALITY CONTRACT: General haulage,

packaging and food.

TURNOVER: Om.

[RAMAGE TRANSPORT)

ROBIN RAMAGE HAS just turned 40, but he's been running his own business for more than 20 years. And very profitably too, according to competitors who take an interest.

Today he runs his operation from an office where visitors sink into sumptuous grey leather sofas, music plays softly from speakers and modern paintings adorn the walls. The offices are decorated throughout in grey, matching the vehicles' livery. The impression of style is further heightened by Ramage himself, sharply dressed in a black suit with a black-and-white striped tie. The echo of Newcastle United's colours is intentional—he has an executive box at St James's Park.

Back in the early 1970s, while still in his teens, he went into business in a prosaic fashion, buying his retiring dad's coal truck for £300 and delivering door-to-door in Consett. When the drift mine closed in 1975 Ramage took his truck and switched to general haulage, initially carrying engineering components for Ingersoll Rand.

Soon IR asked him to put more vehicles on the rood and he borrowed £20,000 for his first depot—"three railway arches under a bridge". Over the years the railway arches were outgrown and Ramage has been in his present depot, his third, for 10 years.

Some 4,600m2 of warehousing is used mainly by two customers, foodstuffs supplier Ridpath Pek and carton manufacturer Field Packaging. The business combines long-distance and local haulage and is set to grow by 15 trucks in the next year: "We've had our 0-licence increased to 100 vehicles, despite a couple of GV9s and a public inquiry," says Ramage. "We should get there in 12 months through expansion of existing clients."

The diverse 250-strong customer base includes clients from Aberlour to Cornwall. Finance director Denise Hodgson, who has been with Ramage for 12 years, produces a list of product groups which includes oil rig production; steel; furniture; waste paper; catalogues; construction products; food and packaging. Ramage says that turnover has risen this year: "We are never looking for work and all our clients seem steady. If one job gets quiet another gets busy." He has recently acquired a 20m lorry loading crane for a new contract.

From a couple of trucks under the railway arches to 85 in a smart depot within two decades seems pretty fast work to CM. So how has Ramage done it? bargain hard," he says, of his vehicle-buying technique, "I don't

know how you can justify £60,000 for a tractive unit, ..60,000—the world's gone mad! I tell local dealers to come to me only if they have special offers and then I might buy two or three." One problem that besets him, like many other hauliers, is the growing shortage of experienced HGV drivers. A recent starter damaged a trailer because he did not know how to put the legs down: "He put 14 tonnes in front on the landing lights and when he dropped the legs the Ext of the trailer went up." He sh kes his head: "Experienced me served drivers are harder and harder to come by."

SIMPSON BROS

THE VALUE OF A SMART LIVERY on a clean, modern vehicle is amply illustrated by the story of how Simpson Bros won its largest account, with Pet Plas Packaging of Leeds.

1 director of Pet Plas spotted one of our lorries on the motorway and approached us," says Peter Simpson. Jean. his wife and fellow director, says this was not the first time customers had arrived that way, Pet Plas now accounts for 23i of the firm's £6m turnover; the work involves carrying plastic bottles from Batley to Sunderland. Fortunately it tied in with an existing contract taking plastic milk bottles from Consett to Leeds, meaning the vehicles were loaded both ways.

Simpson specialises in high-volume/low-weight cargo including bubble film, cardboard packaging and tissues. This has led to the introduction of high-sided curtainsiders to maximise loads. This type of load could hardly be more different from the steel carried by the company's fleet of four trucks when Peter became a partner with his father in 1976. In the same year Peter married lean and a period of steady growth followed, with the fleet expanding to 58 vehicles.

Simpson Bros was founded in 1919 and founder George Emma Simpson, Peter's grandfather, stayed at the helm till he

was 87. "By the time lie retired my father and his brother, my uncle Ralph, were in their fifties and too old to set the world alight," says Peter, who made sure he saw a bit more of the world before joining the family firm. On leaving school he spent several years at truck dealer Union Trucks learning to be a fitter, with a final year selling trucks, The real spring-board for the business was when we moved from BASED: Throckley, Newcastle Upon Tyne. Stocksfield to our current base in Threckley," says FOUNDED: 1919, at Stocksfield, by George lean Simpson. "We were bulging at the seams on Brumwell Simpson. CONTACT: Directors 1.2acres—we now have 4.6 acres." The company also Peter and Jean Simpson. FLEET: 58 vehicles has outposts in Leeds and Milton Keynes where it can including 31 Volvos ("but we are moving park vehicles to service outlying client bases. away from them"), 20 Scanias, five Leyland Like its neighbour, Elddis at Consett, it has introDafs and one Iveco Ford. Buys mainly new. duced new shifts to face the challenge of longer superMost recent purchase was a Leyland Daf in market hours and the demands from two customers, September 1997; two Scanias and two Blowmacan and Plysu, which make plastic bottles for Leyland Dafs are on order for 1 January dairies—an industry which never sleeps. 1998. SPECIALITY CONTRACT: Lightweight, "Three weeks ago we started opening the traffic high-volume packaging materials, office at night and we now have some drivers working TURNOVER: £6m. Friday to Tuesday," says lean. A new customer picked up FACTFILE: SIMPSON BROS

this year is Alba, the South Shields-based hi-fl, radio and TO manufacturer, which should make for a busy Christmas, 'it's the biggest supplier to Argos," says Peter, "and is already earning us £24,000 a month and rising." Simpson Bros carefully monitors vehicle utilisation and now claims to have reached 954 full loads on its 120 jobs a day. "We have stuck out for one-drop loads and avoid partloads," Peter explains. Backloads still present a problem and he admits that 60. are light but the amount earned per vehicle/mile is moving in the right direction.

The company's next step after Christmas will he to open a depot at Leeds. A previous Leeds depot failed, which Peter Simpson blames on staff problems. It closed down last December because poorly managed drivers "were running riot". He is determined not to make that mistake twice: "We must get better at driver training, learning the company right through from the traffic office to the workshop," he says. "It's a big area to cover but it needs addressing. The whole industry is crying out for better training."

ELDDIS TRANSPORT

FACTFILE: ELDDIS TRANSPORT BASED: Consett, with warehousing on four sites. FOUNDED: 1971 as Elddis Transport, although the firm can trace its origins via Thomas Cook back to the 1880s. ;LE ET 120 vehicles and 200 trailers. About 60% are Iveco Ford with 20 Leyland Ws, 10 ERFs two MANs, two Volvos and one Scania. Buys new. Most recent purchase was an Iveco Ford EuroTech 380, Summer 1997. SPECIALITY CONTRACT: Ambient goods to supermarket RDCs. TURNOVER: £11m.

WITH SOME HAULAGE. COMPANIES you have to start at the beginning to understand where they are now. The origins of Elddis Transport can be traced to the 1880s when one Thomas Cook (no relation to the travel firm) set up in general haulage, When Thomas died in 1942 his son Siddle took over and moved into heavy haulage. In 1964 Siddle Cook was taken over by Tayforth, a Scottish operator.

"I stayed on until Tayforth sold out to NFC," says Geoffrey Cook, Siddle's son and now managing director of Elddis Transport. "I started on my own again in 1971 and took the name Elddis, which is my father's Christian name backwards."

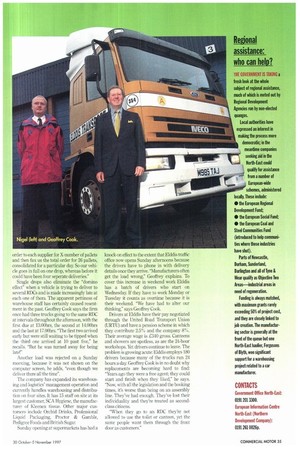

He leans back in his chair and introduces his son Nigel, who is a director and acting transport manager. With Nigel set to take over when Geoffrey retires the Cook family can boast an almost unbroken haulage line stretching back over 100 years.

Today the 120-vehicle fleet specialises in that most modern of haulage niches, servicing the sometimes exasperating supermarket RDCs (regional distribution centres). One of its major local clients is Derwent Valley Foods, a United Biscuits company, better known to television viewers for singing the praises of Medomsley Road, Consett and its Phileas Fogg snack range. "We do 100,000 pallets a year for them," says Geoffrey Cook, proving that the great British couch potato is alive and munching.

Elddis distributes and warehouses other ambient goods, ranging from pet foods to toilet rolls, with thinking services north and south of its Consett base. Both Cooks agree that RDCs are less exasperating than they were, although Geoffrey says: "We had one load we tried to deliver five times. They just had no space and could not handle it" This kind of irritation on what was a timed delivery carried out against the background of mounting road congestion contributes to the misery of the modern drivers' job.

But Nigel says: "At least the supermarkets now talk to the hauliers. Sainsbury will fax an

order to each supplier for X-number of pallets and then fax us the total order for 26 pallets, consolidated for a particular day So our vehicle goes in full on one drop, whereas before it could have been four seperate deliveries."

Single drops also eliminate the "domino effect" when a vehicle is trying to deliver to several RDCs and is made increasingly late at each one of them. The apparent pettiness of warehouse staff has certainly caused resentment in the past. Geoffrey Cook says the firm once had three trucks going to the same RDC at intervals throughout the afternoon, with the first due at 13.00hrs, the second at l 4.00hrs and the last at 17.00hrs. "The first two arrived early but were still waiting to be tipped when the third one arrived at 10 past five," he recalls. "But he was turned away for being late!"

Another load was rejected on a Sunday morning, because it was not shown on the computer screen, he adds, "even though we deliver there all the time".

The company has expanded its warehousing and logistics' management operation and currently handles warehousing and distribution on four sites. It has 15 staff on site at its largest customer, SCA Hygiene, the manufacturer of Kleenex tissue. Other major customers include Orchid Drinks, Professional Liquid Packaging, Proctor & Gamble, Pedigree Foods and British Sugar.

Sunday opening at supermarkets has had a

knock-on effect to the extent that Elddis n-affic office now opens Sunday afternoons because the drivers have to phone in with delivery details once they arrive. "Manufacturers often get the load wrong," Geoffrey explains. To cover this increase in weekend work Elddis has a batch of drivers who start on Wednesday. If they have to work Monday or Tuesday it counts as overtime because it is their weekend. "We have had to alter our thinking," says Geoffrey Cook.

Drivers at Elddis have their pay negotiated through the United Road Transport Union (URTU) and have a pension scheme in which they contribute 2.5% and the company 8%. Their average wage is £340 gross. Canteens and showers are spotless, as are the 24-hour workshops. Yet drivers continue to leave. The problem is growing acute: Elddis employs 180 drivers because many of the trucks run 24 hours a day. Geoffrey Cook is in no doubt why replacements are becoming hard to find: "Years ago they were a free agent; they could start and finish when they liked," he says. "Now, with all the legislation and the booking times, it's worse than being on an assembly line. They've had enough. They've lost their individuality and they're treated as secondclass citizens.

"When they go to an RDC they're not allowed to use the toilet or canteen, yet the same people want them through the front door as customers."

Regional assistance: who can help?

THE GOVERNMENT IS TAKING a fresh look at the whole subject of regional assistance, much of which is meted out by Regional Development Agencies run by non-elected quangos.

Local authorities have expressed an interest in making the process more democratic; in the meantime companies seeking aid in the North-East could qualify for assistance from a number of European-wide schemes, administered locally. These include: • the European Regional Development Fund; • the European Social Fund: • the European Coal and Steel Communities Fund (introduced to help communities where these industries have shut).

Parts of Newcastle, Durham, Sunderland, Darlington and all of Tyne & Wear qualify as Objective Two Areas—industrial areas in need of regeneration.

Funding is always matched, with maximum grants rarely exceeding 50Y of project cost. and they are closely linked to job creation. The manufacturing sector is generally at the front of the queue but one North-East haulier, Fergusons of Blyth, won significant support for a warehousing project related to a car manufacturer.