MAKING FOR EASY BODY MAINTENANCE

Page 48

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

IN order that the body of a commercial vehicle may be kept in good condition with a minimum of expense, it should be designed to stand up to hard wear and tear and

be easy to clean. The life of the bodywork depends on the design, the materials selected for its construction and fittings, and the nature of the load.

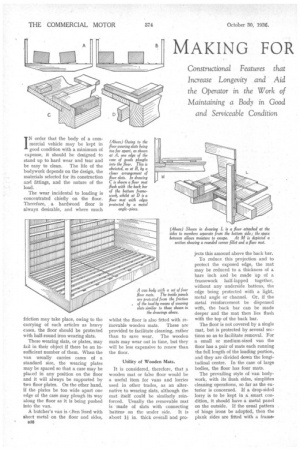

The wear incidental to loading is concentrated chiefly on the floor. Therefore, . a hardwood floor is always desirable, and where much friction may take place, owing to the carrying of such articles as heavy cases, the floor should be protected with half-round iron wearing slats.

These wearing slats, or plates, may fail in their object if there be an insufficient number of them. When the van usually carries cases of a standard size, the wearing plates may be spaced so that a case may be placed in any position on the floor and it will always be supported by two floor plates. On the other hand, if the plates be too wide apart one edge of the case may plough its way along the floor as it is being pushed into the van.

A butcher's van is (..f ten lined with sheet metal on the floor and sides, a38

whilst the floor is also fitted with removable wooden mats. These are provided to facilitate cleaning, rather than to save wear. The wooden mats may wear out in time, but they will be less expensive to renew than the floor.

Utility of Wooden Mats.

It is considered, therefore, that a wooden mat or false floor would be a useful item for vans and lorries used in other trades, as an alternative to wearing slats, although the mat itself could be similarly reinforced. Usually the removable mat is made of slats with connecting battens on the under side. It is about 1.1 in. thick overall and pro

jects this amount above the back bar.

To reduce this projection and to protect the exposed edge, the mat may be reduced to a thickness of a bare inch and be made up of a framework half-lapped together, without any underside battens, the edge being protected with a light, metal angle or channel. Or, if the metal reinforcement be dispensed with, the back bar can be made deeper and the mat then lies flush with the top of the back bar.

The floor is not covered by a single mat, but is protected by several sections so as to facilitate removal. For a small or medium-sized van the floor has a pair of mats each running the full length of the loading portion, and they are divided down the longitudinal centre. In the case of large bodies, the floor has four mats.

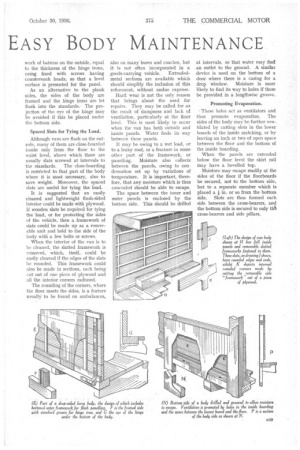

The prevailing style of van bodywork, with its flush sides, simplifies cleaning operations, so far as the exterior is concerned. If a drop-sided lorry is to be kept in a smart condition, it should have a metal panel on the outside. If the usual pattern of hinge irons be adopted, then the plank sides are fitted with a frame work of battens on the outside, equal. to the thickness of the hinge irons, ming fixed with screws having countersunk heads, so that a level surface is presented for the panel.

As an alternative to the plank sides, the sides of the body are framed and the hinge irons are let flush into the standards. The projection of the eye of the hinge may be avoided if this be placed under the bottom side.

Spaced Slats for Tying the Load.

Although vans are flush on the outside, many of them are close-boarded inside only from the floor to the waist level, above which there are usually slats screwed at intervals to the standards. The close-boarding is restricted to that part of the body where it is most .necessary, also to save weight. Moreover, the spaced slats are useful for tying the load.

It is suggested that an easily cleaned and lightweight flush-sided interior could be made with plywood. If wooden slats be required for tying the load, or for protecting the sides of the vehicle, then a framework of slats could be made up as a removable unit and held to the side of the body with a few bolts or screws.

When the interior of the van is to be cleaned, the slatted framework is removed, which, itself, could be easily cleaned if the edges of the slats be rounded. This framework could also be made in sections, each being cut out of one piece of plywood and all the interior corners radiused.

The rounding of the corners, where the floor meets the sides, is a feature usually to be found on ambulances, also on many buses and coaches, but it is not often incorporated in a goods-carrying vehicle. Extrudedmetal sections are available which should simplify the inclusion of this refinement, without undue expense.

Hard wear is not the only reason that brings about the need for repairs. They may be called for as the result of dampness and lack of ventilation, particularly at the floor level. This is most likely to occur when the van has both outside and inside panels. Water finds its way between these panels.

It may be owing to a wet load, or to a leaky roof, or a fracture in some other part of the framework, or panelling. Moisture also collects between the panels, owing to con. densation set up by variations of temperature. It is important, therefore, that any moisture which is thus concealed should be able to escape.

The space between the inner and outer panels is enclosed by the bottom side. This should be drilled at intervals, so that water may find an outlet to the ground. A similar device is used on the bottom of a door where there is a casing for a drop window. Moisture is more likely to find its way to holes if these be provided in a lengthwise groove.

Promoting Evaporation.

These holes act as ventilators and thus promote evaporation. The sides of the body may be further ventilated by cutting slots in the lower boards of the inside matching, or by leaving an inch or two of open space between the floor and the bottom of the inside boarding.

When the panels are extended below the floor level the skirt rail may have a bevelled top.

Moisture may e-srape readily at the sides of the floor if the floorboards be secured, not to the bottom side, but to a separate member which is placed a in. or so from the bottom side. Slots are thus formed each side between the cross-bearers, and the bottom side is secured to only tlA cross-bearers and side pillars.