HINTS ON MAINTENANCE.

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

442.— Building up a Worn Pump Spindle on a Dennis Engine.

Considerable wear sometimes takes place on the pump spindle of the 3-ton Dennis coach chassis after about 12 months' service. 'This is due to two causes, water action on the steel spindle, and constant tightening of the gland nut without oiling the gland afterwards. The spindle and pinion form a unit, and to replace them is expensive. However, such replaeement can be avoided if the spindle be turned down where wear has taken place and a phosphorbronze bush pressed into position and pegged. The water does not affect this metal at all,. and if oil be put on to the shaft after each tightening of the gland nut the bush Will stand up considerably better than a steel spindle.

443. —A Ratchet for the Commer Car. Foot Brake.

The Commer Car is an excellent machine in many -ways, but, like all others, the older models embody one or two little features where improvements can be effected.

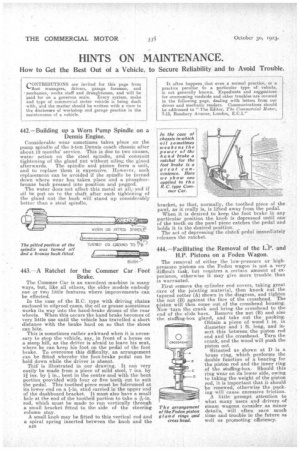

In the case of the RC. type with driving chains enclosed in oilproof cases, the oil or grease sometimes works its way into the hand-brake drums of the rear wheels. When this occurs the hand brake becomes of very little use until the vehicle has travelled a short distance with the brake hard on so that the shoes can bite.

This is sometimes rather awkward when it is necessary to stop the vehicle, say, in front of a house on a steep hill, as the driver is afraid to leave his seat, where he can keep his foot on the pedal of the foot brake. To overcome this difficulty, an arrangement can be fitted whereby the foot-brake pedal can be held down while the driver is absent.

Thif is illustrated in our drawing. It can very easily be made from a piece of mild steel, 7 ins, by ins, by j in., bent in the centre and with the bent portion provided with four or five teeth cut to suit the pedal. This toothed piece must be fulcrumed at its lower end on a stud carried in the upper end of the dashboard bracket. It must also have a small hole at the end of the toothed portion to take a rod, which must be made to run vertically through a small bracket fitted to the side of the steering column stay.

A small knob may be fitted to this vertical rod and a spiral spring inserted between the knob and the

bracket, so that, normally, the toothed piece of the pawl, as it really is, is lifted away from the pedal. When it is desired to keep the foot brake in any particular position the knob is depressed until one' of the teeth on the pawl piece catches the pedal and holds it in the desired position. The act of depressing the clutch' pedal immediately releases the ratchet.

444.—Facilitating the Removal of the L.-P. and H.P. Pistons on a Foden Wagon.

The removal of either the low-pressure or highpressure pistons on the Foden wagon is not a very difficult task, but requires a, certain amount of experience, otherwise it may give more trouble than is warranted.

First remove the cylinder end covers, taking great care of the jointing material, then knock out the tapered cotter (A) shown in the diagram, and tighten the nut (B) against the face of the crosshead. The piston will then come out of the crosshead housing. Now turn the crank and bring the crosshead to the end of the slide bars. Remove the nut (B) and also the stuffing-box gland, and take out the packing. Obtain a piece of wood 1 in. in diameter and 1 ft. long, and insert this between the piston rod end and the crosshead. Turn the crank, and the wood will push the piston out -Situated as shown at D is a brass ring, which performs the double function of a bearing for the piston rod and the inner ring of the stuffing-box: Should this ring wear on its lower side, awing to taking the weight of the piston rod, it is important that it should be renewed, otherwise the packing will cause excessive friction.

A little prompt attention to what many users and drivers of The arrangement steam wagons consider, as minor of the Foden piston details, will often save much gland rings and time and trouble in the future as cross head. well as promoting efficiency.