Is Producer Gas Worth While?

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

Whilst Oil Engine Conversions Give Promise of Good Results, Only Extreme Necessity Would Justify the Change-over in Petrol Units THE extent of the cut in fuel supplies is far more severe than most operators expected, and essential goods-transport services will have to be drastically curtailed. Inquiries have already been received by The Commercial Motor on the practical aspects of using producer gas, in order to supplement the meagre quantity of liquid fuel that will be available during the next few months. The scheme is practicable, as was proved during the war, but what of the economics of such a conversion ?

So far as petrol engines are concerned, conversion to producer gas in place of petrol, and without modifying the power unit, will result in extremely poor efficiency, the power loss being as high as 50 per cent. Much better results are likely in the case of oil engines, as tests have shown that not only can the consumption of liquid fuel be much reduced, but that the power loss can be negligible.

Extensive tests have been carried out by the Ministry of Fuel and Power and the Ministry of Transport, in conjunction with the Department of Scientific and Industrial Research. A report on the subject was published last August (The Commercial Motor, August 17).

Although tests were made with both petrol and oil-engined vehicles, the report made it clear that only in extreme cases was the conversion of a petrol engine to the use of producer gas worth while. Such modifications as can be made to a petrol engine by the operator concern the ignition timing and the compression ratio. The ignition should be advanced by about 10 degrees to compensate for the slower-burning characteristics of the gas.

Higher compression is also desirable, but because of the need for the use of petrol for starting up and in other circumstance* this is considered to be impracticable. In view of the occa sional use of petrol it would be necessary to provide manual means for retarding the ignition while running on petrol.

With the oil engine the necessary modifications are not complicated and the ignition problem is more simple to deal with. To compensate for the slow burning of the charge, the injection timing is advanced to about 32 degrees before top dead centre. The report pointed out that this might vary with the type of engine being converted. (An A.E.C. 7.7-litre engine was concerned in the report.) Modifications are also called for in he injection pump, not necessarily tecause producer gas is being used, but )ecause the overriding purpose is to ,ave liquid fuel.

In the case of the C.A.V. equipment itted to the A.E.C. engine, there was in overriding device, operated fromthe :ab, by which the fuel delivery from he pump could be cut down from -the iormal amount to the minimum injecion quantity necessary for good corn)ustion when running on producer gas. "-Tull injection, however, could be Attained for running the engine to get he producer plant in action.

An ideal pump would be one which ifforded an injection quantity sufficient o effect good combustion of the pro!neer gas at any given engine speed tnd further, a unit of the simplest posiible form which would enable conrersions to be carried out quickly and theaply. Given a pump in sound nechanical condition, the necessary nodigcations to the C.A.V. Pump should cost £4-£5.

To improve the fuel-delivery speed :haracteristies of the pump, modificaions were also made to the governor lyweights by introducing springs and Ilates of a suitable rating which inabled the flyweights to control pump.ack movement at critical speeds.

On the ground of operational efficiency, it is considered that producergas conversions should be employed on medium or long-distance work rather than for short-journey delivery services.

One of the A.E.C. vehicles used for the tests was a Mammoth Minor having a payload of 10 tons 2 cwt. A 21-in. hopper was used, and this carried sufficient solid fuel for a non-stop journey of 200 miles. One of the most interesting findings of these tests was that the oil-fuel consumption was at the rate of 40 m.p.g. The liquid fuel is, of course, injected as the ignition medium and not as the power producer.

The results obtained with a doubledeck bus were also satisfactory, the liquid-fuel consumption rate, on 244 miles of continuous operation, being 43 m.p.g.

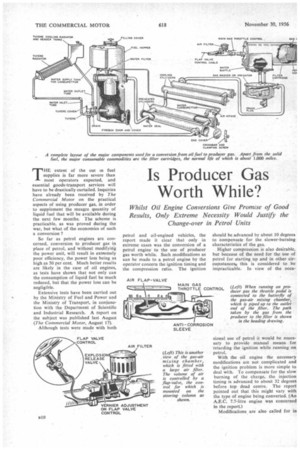

Included in the report was a complete layout of the units employed in a producer-gas conversion for an oil engine and this is reproduced. The Commercial Motor is not aware of any concern which is able to supply these units, and operators who are interested arc advised to address their inquiries to the Ministry of Fuel and -Power, Thames House, Millbank, London, S.W.1.