Science Applied to Industry.

Page 5

Page 6

Page 7

If you've noticed an error in this article please click here to report it so we can fix it.

Instruments and Materials Brought Into Being as the Result of Researches and Experiments in the Laboratory at the Works of Rudge-Whitworth, Ltd., are Available for Universal Use.

Rudge-Whitworth, Ltd. of Coventry, Birmingham, '

and elsewhere is known to the man in the street by its bicycles, to the motorist by its motor-bicycles and detachable *heels, to the trade and cur technical readers by reason of the, scientific methods which it applies in the prosecution of its business. We ourselves share with many an especial appreciation of its broadmindedness in respect of the disclosure of its methods of attaining success. rypical of this last-named attribute was the attitude aken up by Mr. Pugh, of that company, shortly iefore the war, with regard to wire-wheel manufac-nre, as expressed in an open letter to a contem)orary in which he described the difficulties to be net with in the construction of wire wheels, and txplained how best to overcome them.

Not so much is known of an interesting side line if the company's business, which has for its object ,he sale and manufacture of materials and instrunents for the treatment and testing of metals. The lepartment, by reason of its special nature, must be

comparatively small one, and we have for some time )8,st been curious as to the reason for its existence, ince the additional dividend which it could earn vould not be likely to affect to any appreciable exent the fortunes of Rudge-Whitworth, Ltd., as a .ommercial house. A convefsation with Mr. H. L. leathcote, who is in charge of the research departnent, which concerns itself with the manufacture Lnd sale of these materials and instruments, to;ether with one or two deductions on our part, served o convince us that this was merely another exempliication of that broadmindedness which we have Iready observed at being a trait of the company.

The Research Department.

Our subject may best be attacked by giving a brief iistory of the research department of nudge-Whitvorth, Ltd. in similar words to those in which it was 'resented t;) us by Mr. Heathcote on the occasion of .ur visit to the Coventry works. The department ,as opened as a laboratory, with Mr. Heathcote, rho is well known in metallurgical circles, in charge. ts object was to apply science to the manufacture nd construction of nudge-Whitworth bicycles so ir as was commercially practicable. One of the first esults was the discovery of an improved system of lating steel, which was patented and which is widely sed at the present time. Some nine or ten years ago Mr. Heathcote, as a esult of his own investigations carried out in the ormal course of business on case-hardened steel .arts, came to the conclusion that the case-hardenig material generally employed was capable of imrovement. Amongst the objections which he had

to the material then used was that owing to its slow action it was difficult to obtain consistent results even from a, number of parts hardened and carburized in the same pot, owing to the fact that small articles near the outside of the pot might be rather overheated and receive more than the due proportion of carbon, the others in the centre which would nevertheless not be treated sufficiently. He, therefore, set for himself the problem of discovering a more uniform carburizer.

The Problem: To ,Find an Efficient Carburizer.

He attacked this problem, so to speak, from the ground upwards taking for his preliminary experiments the simplest possible materials. The first process in connection with the case-hardening of steel is to cause a, proportion of carbon to combine chemically with the outer layers of the steel ; this is done by heating the steel to-a, pre-arranged tem perature in contact with material of which the prin cipal constituent is carbon. Coal was tried first, at being a comparatively cheap material containing a. large percentage of the requisite carbon. Difficulty was met in. persuading the carbon from the coal to perform its duties as a carburizer ; moreover, at the same time, and during the same process, sulphur also was liberated, which combined with the steel as well. The results were, therefore, unsatisfactory. The same difficulties were experienced with coke, though perhaps to a lesser degree, and only by using charcoal, which is practically pure carbon, was the sulphur element excluded. The objection to charcoal was its extreme slowness of action, and in order to assist this material Mr. Heathcote looked round for a catalyzer, that is to say, a, material which would act in a manner to facilitate the chemical combination between the carbon and the steel whilst at the same time itself remaining for all practical purposes unchanged. A similar instance is the use ef pure metallic nickel in connection with the cracking of paraffin in order to obtain from the paraffin the lighter constituents like petrol. The heated paraffin is brought into contact with the pure nickel which has the effect of quickening the process of dissolution of the heavy paraffin into its lighter constituents. We are only permitted to say that Mr. Heathcote was successful in his search, and a satisfactory catalyzer was found; moreover, it was of such a nature that by means of a special process it was possible to coat every. particle of the carbon used with it. The material is economical.in use, only that quantity being consumed which actually combines with the steel. This is the case provided the pot is not opened until it has cooled somewhat. Alternatively some of the carbon, when exposed to the air at high temperature, burns and is thus lost.

The Result Satisfactory.

Other experiments conducted by Mr. Hea.thcoto concerned the heat conductivity of the various carburizers. He found, as might be expected, that these qualities varied to a considerable degree with the size of the particles of the material used. He considered carefully this side of the question in making his final choice as to the form in which his case hardening compound would give the best results. 'Eventually he found that. he would be able to reduce the normal time for carbonization by so much as 40 per cent. It goes without saying that Mr. Heathcote had some little difficulty in persuading the management, and particularly the metallurgical department, to accept his material for general use.. We have, all of us, at one time or another, come into contact with that peculiar attitude which strongly objects to the intrusion of new methods or new materials into an established works organization. It will suffice here if we say that eventually he succeeded. Meantime, the activities of his department were not dormant in other directions. Several extremely useful, and, considering their utility, very inexpensive tools were invented and patented by that department.

An Accurate Brinell Testing Machine Which Can

• be Carried in the Pocket.

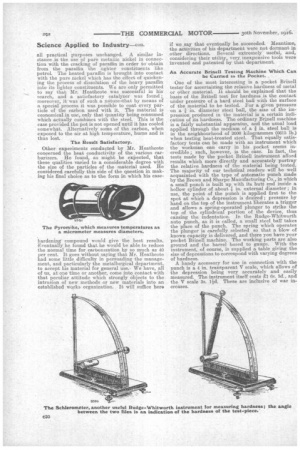

One of the most interesting is a pocket Brinell tester for ascertairring the relative hardness of metal or other material. It should be explained that the basis of the Brinell test for hardness is the contact under pressure of a hard steel ball with the surface of the material to be tested. For a given pressure on a in, diameter steel ball, the size of the impression produced in the material is a. certain indication of its hardness. The ordinary Brinell machine is a, fairly substantial apparatus, and the usual load applied through the medium of a I in. steel ball is in the neighbourhood of 3000 kilogrammes (661.5 lb.) when testing heat-treated steel. That equally satisfactory tests can be made with an instrument which the workman can carry in his pocket seems in.credible • such, however, is the case. In fact, the tests made by the pocket Brinell instrument afford results which more directly and accurately portray the relative hardness of the material being tested. The majority of our technical readers will be well acquainted with the type of automatic punch made by the Brown and Sharpe Manufacturing Co., in which a small punch is built up with its butt end inside a hollow cylinder of about in. external diameter ; in use' the point of the punch is applied first to the spot at which a depression is desired ; pressure by hand on the top of the instrument liberates a trigger and allows a spring-operated plunger to strike the top of the cylindrical portion of the device, thus causing the indentation. In the Rudge-Whitworth auto punch, as it is called, a small steel ball takes the place of the punch. The spring which operates the plunger is carefully selected so that a blow of known capacity is delivered, and there you have your pocket Brinell machine. The working parts are also ground and the barrel bored to gauge. With the instrument, of course, is supplied a table giving the size of depressions to correspond with varying degrees of hardness.

A handy accessory for use in connection with the punch is a 4 in. transparent V scale, which allows of the depression being very accurately and easily measured. The instrument itself costs R1 Os. 3d_, and the V scale 3s. hid. These are inclusive of war increases. A Modification for a Special Purpose.

A modification of this hardness tester has been designed for the purpose of testing the material et cartridge cases. This device is in the form of a'pauof nliers, one leg of which is cylindrical in form and enters the cartridge case the second leg has a flat face with a. hole in it, through which protrudes a portion of a small steel ball. Behind the lball is a spring-operated plunger designed to exert a known, pressure on the ball when the latter is flush with the face of the pliers. Consequently, if the portion of the cartridge case be held over the cylindrical leg and the pliers be then closed the outer surface of the case will bed on the flat face of the second leg of the pliers ;' the ball will then be pressing upon the metal .of the case with the pre-determined pressure and will cause a depression to be formed in the material of the cartridge ease, its size depending upon the hardness of that material.

Testing the Hardness of Cylindrical Bodies.

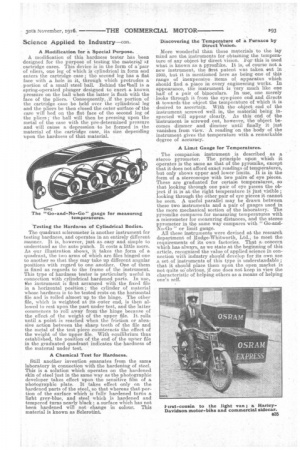

The quadrant sclerometer is another instrument for testing hardness' and operates in an entirely different manner. It is, however, just as easy and simple to understand as the auto punch. It costs a little more. As our illustration shows, it takes the form .of a quadrant, the two arms of which are files hinged one to another so that they may take up different angular positions with regard to one another. One ef them is fixed as regards to the frame of the instrument. This type of hardness tester is particularly useful in connection with cylindrical hardened parts. In use, Ike instrument is first arranged with the fixed file in a horizontal position • the cylinder of material whose hardness is to be tested rests on the horizontal file and is rolled almost up to the hinge. The other file, which is weighted at its outer end, is then allowed to rest upon the part under test, and the latter commences to roll away from the hinge because of the effect of the weight of the upper file. It rolls until a point is reached when the friction or abrasive action between the sharp teeth of the file and the metal of the test piece counteracts the effect of the weight of the upper file. With equilibrium thus established, the position of the end of the upner file in the graduated quadrant indicates the hardness of the material under test.

A Chemical Test for Hardness.

Still another invention emanates from the same laboratory in connection with the hardening of steel. This is a solution which operates on the hardened skin of steel just in the same way as the photographic developer takes effect upon the sensitive film of a photographic plate. It takes effect only on the hardened partsof the steel, so that whereas that portion of the surface which is fully hardened turns a light grey-blue, and steel which is hardened and tempered turns nearly black ; a surface which has not been hardened will not change in colour. This material is known as Sclerotint. Discovering the Temperature of a Furnace by Direct Vision.

More wonderful than these materials to the lay mind are the instruments for obtaining the temperature of any object by direct Vision. leer this is used what is known as a, pyrontike. It is, A course not a new instrument, the first patent was taken out in 1905, but it is mentioned here as being one of this range of inexpensive items of apparatus which should find a, place in every engineering works. In appearance, ace instrument is very much like one half of a pair of binoculars. In use, one merely looks through it from the eye-piece end and directs it towards the object the temperature of which it is desired to ascertain. With the object end of the instrument screwed well in, the material being inspected will appear clearly. As this end of the Instrument is screwed out, however, the object becomes dimmer and dimmer until finally it just vanishes from view. A reading on the body of the instrument gives the temperature with a remarkable degree of accuracy.

A Limit Gauge for Temperatures.

The companion instrument is described as a stereo pyrometer. The principle upon which it operates is the same as that of the pyromike, except that it does not afford exact readings of temperatures, but only shows upper and lower limits. It is in the form of a stereoscope with two pairs of eye pieces. These are graduated for certain temperatures, so

that looking through one pair of eye is the object if it is at the right temperature s just visible ; looking through the other pair of eye pieces it cannot be seen. A useful parallel may be drawn between these two instruments and a pair of gauges used in the more mechanical section of the laboratory. The pyromike compares for measuring temperatures with a micrometer for measuring distances, and the stereo pyrometer in the same way compares with " Go-andNo-Go " or limit gauge. All these instruments were devised at the research department of lludge-Whitworth, Ltd., to meet the rectuirements of its own factories. That a concern which has always, as we state at the beginning of this article, recognized the value of applied science in connection with industry should develop for its own use a set. of instruments of this type is understandable ; that it should place them upon the open market is not quite so' obvious, if one does not keep in view the characteristic of helping, others as a means of helping one's self.