Contributions from Drivers and Mechanics.

Page 17

Page 18

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY for the Best Communication Received, and One Penny a Line of ten words for any thing else published.

Drivers of commercial-motor vehicles and tractors, and mechanics and foremen of garages or shops, are invited to send short contributions on any subject which is likely to prove of interest to our readers. Work. shop tips and smart repairs ; long and successful runs ; interesting photographs : all are suitable subjects. Send a post-card, OY a letter, or a sketch to us—no matter how short, or how written, or how worded. We will "knock it into shape" and prepare sketches, where necessary, before publication. The absence of a sketch does not disqualzfy for a prize. When writing use one side of the paper only and mention your employer's name as a guarantee of bona fides. Neither your own nor your employer's name will be disclosed. Payment will be made immediately after publication. Address watt, letters to 'The Editor, THE COMMERCIAL MOTOR, 7-15, Rosebery Avenue, London, E.G.

A Tire Pump from Scrap.

[967] " H.S." (Luton) writes :—" I recently made quite a serviceable double-throw pump out of scrap stuff. It has now been in use satisfactorily for some while for blowing up pneumatic tires on cabs and light delivery vans. " A friend of mine had an engine on his hands, of which the crankshaft was broken. We decided to use this and two connecting rods and the flywheel, in order to make up a useful pump. I cut the broken end off the crankshaft and mounted the latter on a suitable wrought-iron stand. I next cut off the big ends of the connecting rods, and these I drilled and tapped Whit. 1 then procured two large tirepump barrels, which had been out of work for a. long while, and, after removing the original piston-pods, I fitted new and longer ones which were made out of

stuff. These new rods were fixed to the old plungers and, at the other end, into the old big ends,

with lock nuts. I brazed a piece of plate on to each side or each pump, and these 1 mounted on a short rocking shaft, so that the • pumps could oscillate. A short length of #1-in gas pipe and a length of hose. with a cock and a gauge completed the outfit. We were thus able to reach any car which did not happen to be near our pump, which was too cumbersome to move about very easily. We fixed the whole arrangement near to a drilling machine, so that we could use one of its pulleys for a belt drive on to the flywheel of our pump. The device was clumsy, but it was cheap and it has proved very useful."

Testing Valve Springs.

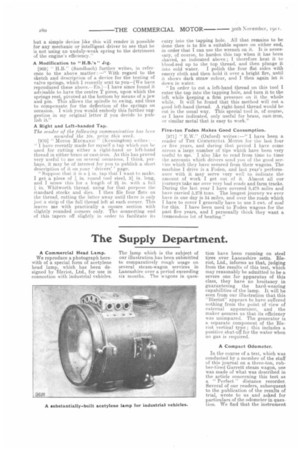

i06s1 " HAI" (Cheshire) writes : "T should like ti) describe a simple, but useful spring tester. Your readers will agree that it is most important for the efficient running of a .petrol engine that the valve springs should be periodically tested, in order that it may be assured that they are giving the necessary pressures for which the designer had made provision in the first place. There is really no certain method of testing such springs while the engine is working, and often compression troubles arise, owing to the fact that the springs are not doing their work properly: such troubles are more often than not attributed to the valves ; no thought is given to the springs which control them.

" The little device which I here suggest is intended for use when the engine is being overhauled and when the valve springs have been dismounted. The sketch [We have had this redrawn.—ED.] needs little from me to add in the matter of description. The jig itself is mounted on a piece of stout board. Two pieces of an old scale are screwed on to the board, care being

taken to see that these are placed at exactly the same heights ; the two springs are tested at one time, and these, as will be seen, are mounted on guides. If there be any difference in their lengths, the short one should be packed up until they are equal. The spring-steel bar is then placed across the top of them, and pressure is applied by means of the screw-down nut. One of the springs must either be one which has been adopted as a standard, or else some spring which has already been tested with it and found to be equal to it. This 'known ' spring, if I may call it so, I place on the left-hand guide, the doubtful one being on the other side. Clearly, as the springs are equidistant from the centre, and if the spring which we are testing be exactly equal to the reference spring, the indications on the scales should at all times be the same. If the spring has lost strength, it will be readily detected by the fact that the bar will fall on that side much more quickly than on the other. Experience will teach very quickly as to what are the limits that can be allowed for working conditions,

but a simple device like this will render it possible for any mechanic or intelligent driver to see that be is not using an unduly-weak spring to the detriment of the engine's efficiency."

A Modification to "H.B.'s" Jig.

[969] " H.B." (Sandbach) further writes, in reference to the above matter :—" With regard to the sketch and description of a device for the testing of valve springs, which I recently sent to you—{V e have reproduced these above.—ED.]—I have since found it advisable to have the centre T piece, upon which the springs rest, pivoted at the bottom by means of a jaw and pin. This allows the spindle to swing, and thus to compensate for the deflection of the springs on occasion. I wish you would embody this further suggestion in my original letter if you decide to publish it."

A Right and Left-handed Tap.

The sender of the following communication has been awarded the 10s. prise this week. [970] " MOTOR MECFIAN1C: " (Kensington) writes : " I have recently made for myself a tap which can be used for cutting either a right-hand or left-hand thread in either brass or cast-iron. As this has proved very useful to me on several occasions, I think, perhaps, it. may be of interest. for you to publish a short description of it on your drivers" page. " Suppose that it is al in. tap that I want to make. I get a piece of 1 in. round tool steel, 31 in. long, and I screw this for a length of 21 in. with a full

in. Whitworth thread. using for that purpose the standard stocks and dies. I then file four flats on the thread, cutting the latter away until there is only just a strip of the full thread left at each corner. This leaves me with practically a square section with slightly rounded corners only. The connecting end of this tapers off slightly in order to facilitate its entry into the tapping hole. All that remains to be done then is to file a suitable square on either end, in order that I can use the wrench on it. It is necessary, of course, to harden this tap when it has been shaved, as indicated above ; I therefore heat it to blood-red up to the top thread, and then plunge it, into cold water. I polish the four flat sides with emery cloth and then hold it over a bright fire, until it shows dark straw colour, and I then again let it down in water.

"in order to cut a left-hand thread on this tool I enter the tap into the tapping hole, and turn it to the left while keeping a firm pressure on it the whole while. It will he found that this method will cut a, good left-hand thread. A right-hand thread would be cut in the usual way. This special tool is, of course, as I have indicated, only useful for brass, cast-iron, or similar metal that is easy to work."

Five-ton Foden Makes Good Consumption.

[971] " E.W." (Oxford) writes :—" I have been a reader of THE COMMERCIAL Murcia for the last four pr five years, and during that period I have come across a large number of tips which have been very useful to me. I also like to read from time to time the accounts which drivers send you of the good service which they have secured from their wagons. The machine I drive is a Foden, and last year's performance with it may serve very well to indicate the amount of work I get out of it Almost all our journeys take me over very bad roads and farm tracks. During the last year I have covered 8,478 miles and have carried 5,276 tons. The longest journey we ever have in one day is 54 miles, and over the roads which I have to cover I generally have to use 3 cwt. of coal for this. I have been used to Foden wagons for the past five years, and I personally think they want a tremendous lot of beating."