By P. G. TUCKER

Page 38

Page 39

Page 40

Page 43

If you've noticed an error in this article please click here to report it so we can fix it.

There are Many Ways in Which Tyres can be Preserved From an Untimely End, and This Article Sets Out the Known Causes of Premature Wear, and the Most Logical Method of Preventing it

AN expensive item in the running costs of a commercial vehicle is that for tyres, and yet every year thousands find their way to the scrapheap long

before their time. A set of six 36 by 8 tyres costs £115 4s., and, assuming the average life of a tyre to be 30,000 miles, the cost works out as nearly as possible to 0.9d. per vehicle-mile. That is nearly Id. per vehiclemile under favourable conditions of usage.

Route conditions and types of service play a big part in determining tyre mileage, but most of the factors under these headings may be beyond the control of any indbiidual operator. Efficient tyre maintenance, however, which is under his control, can bring about a substantial reduction in costs per tyre-mile.

I should mention here that some tyre companies sell tyres on a mileage basis, and it will be found that they take great care in the efficient maintenance of mileagecontract tyrcs, to the extent, usually, of employing a special department of tyre fitters. Those operators with fleets of sufficient size to justify the establishment of such a department would do well to consider the idea.

What Tyre Markings Mean

Before dealing with the building up of an efficient maintenance service, I should like to explain the accepted system for marking tyre sizes. It should be understood that size markings are nominal and do not give the actual dimensions. Reference to the tyre section drawing will show the basic dimensions of a tyre and rim; they apply to a wheel with an unloaded inflated tyre.

High-pressure equipment is marked with the nominal overall diameter of the tyre, and the width or section. For example, 32 by 6 refers to an overall diameter of 32 ins., and a tyre width of 6 ins. In the case of lowpressure tyres, these are marked with the section of the tyre and the diameter of the rim. A 9.00 by 16 tyre,

• for instance, has a tyre width of 9 ins., and the diameter of the rim at the base to which the cover is to be fitted is 16 ins.

As these dimensions are only nominal, it is undesirable to calculate the overall diameter of the tyre from the markings given on low-pressure tyres. The tyre makers' specification will supply this information. In the case of a high-pressure tyre, it is permissible to calculate the rim diameter from the markings, by subtracting twice the tyre section from the overall tyre diameter. In some instances, low-pressure tyres are marked with the tyrewidth dimension in millimetres, such as 170 by 20, which is a 170 mm., or 6.70-in.-section tyre, for a 20-in. rim.

Dealing with the factors controlling tyre wear, here are some of the more important which are under the direct control of the operator. First of all there is the positioning of partly worn tyres, proper attention to which can lead to a reduction in tyre costs of as much as 50 per cent.

In the case of light four-wheeled vans, the maximum total tread life will be obtained if all four tyres—and the spare—be given a simultaneous move around one place every 5,000 miles. When the five tyres are becoming smooth, new ones should be introduced, preferably on the near side. If the proportional load on the rear axle be rather high, as is often the case, it may be advisable to abandon a system of tyre rotation, getting as high a mileage as possible out of new tyres on the front axle, before moving them to the more heavily loaded rear axle to be run out.

Ask the Maker Tyre positioning problems on vehicles having twin rear axles, four-wheel drive, six-wheel drive, twin front axles, ex-Army machines with special types of tyre, and so on, are more complicated, and advice should be sought from the service department of a tyre maker.

In the case of machines having twin rear tyres, tread wear on the outer pair of tyres will be slightly faster than on the inner pair, and will, therefore, wear to a smaller circumference. Any tyre changes should ensure that the diameter of the inner tyre is at least no smaller than that of the outer.

In changing them around, the more worn outer tyre from the off-side rear wheel should be changed with the outer tyre on the near-side rear wheel, and similarly with the inner wheel tyres.

When vehicles are working under severe load conditions, it pays to adopt what is termed differential twin ning, the more worn tyre being on the inner wheel. In such cases the inner tyre should be between in. and

in. smaller in diameter than the outer tyre. With 7-in. and larger high-pressure equipment, additional relief can be given by running the inside tyre of each pair—if the wear be equal—at 15 per cent. lower pressure than the outside ones. If this be done, it is essential to keep a regular check on the relative pressures.

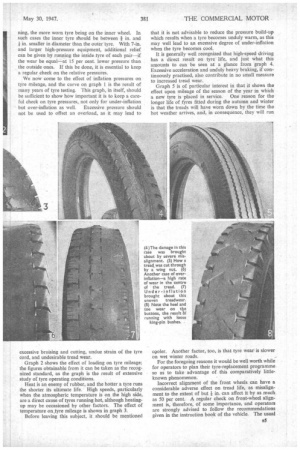

We now come to the effect of inflation pressures on Lyre mileage, and the curve on graph 1 is the result of many years of tyre testing. This graph, in itself, should be sufficient to show how important it is to keep a careful check on tyre pressures, not only for under-inflation but over-inflation as well. Excessive pressure should not be used to offset an overload, as it may lead to excessive bruising and cutting, undue strain of the tyre cord, and undesirable tread wear.

Graph 2 shows the effect of loading on tyre mileage; the figures obtainable from it can be taken as the recognized standard, as the graph is the result of extensive study of tyre operating conditions.

Heat is an enemy of rubber, and the hotter a tyre runs the shorter its ultimate life. High speeds, particularly when the atmospheric temperature is on the high side, are a direct cause of tyres running hot, although heatingup may be occasioned by other factors. The effect of temperature arks-tyre mileage is shown in graph 3.

Before leaving this subject, it should be mentioned that it is not advisable to reduce the pressure build-up which results when a tyre becomes unduly warm, as this may well lead to an excessive degree of under-inflation when the tyre becomes cool.

It is generally well recognized that high-speed driving has a direct result on tyre life, and just what this amounts to can be seen at a glance from graph 4. Excessive acceleration and unduly heavy braking, if continuously practised, also contribute in no small measure to increased tread wear.

Graph 5 is of particular interest in that it shows the effect upon mileage of the season of the year in which a new tyre is placed in service. One reason for the longer life of fyres fitted during the autumn and winter is that the treads will have worn down by the time the hot weather arrives, and, in consequence, they will run

cooler. Another factor, too, is that tyre wear is slower on wet winter roads.

For the foregoing reasons it would be well worth while for operators to plan their tyre-replacement programme so as to take advantage of this comparatively littleknown phenomenon.

Incorrect alignment of the front wheels can have a considerable adverse effect on tread life, as misalignment to the extent of but in. can affect it by as much as 50 per cent. A regular check on front-wheel alignment is, therefore, of some importance, and operators are strongly advised to follow the recommendations given in the instruction book of the vehicle. The usual

advice is to set the wheels between parallel and in.

toe-in.

The application of the features touched upon is largely in the hands of the operator or his engineer, but in some cases, such as the maintenance of correct tyre pressures and the correct positioning of tyres, the work would usually be given over to specially detailed tyre fitters. The most important tasks in maintenance for which these fitters should be made responsible may now be outlined.

The number of men needed will vary according to the number of vehicles to be maintained. In the case of a small fleet, the tyre fitter might not be needed full time, so that his work could be combined with other duties. In the case of a large fleet, with all the vehicles operating from a central garage, a first-class tyre fitter could handle up to 70 vehicles, provided that he had an assistant for wheel changing.

On the other hand, if the vehicles were scattered at several different garages, 35 might be the maximum number which one tyre fitter could effectively deal with. It is essential that those directly responsible for tyre maintenance be equipped with a full kit of tools, together with adequate supplies of repair material. It is futile to expect efficient service from a department which is not properly equipped.

As to the duties of a tyre-maintenance man, he should know the correct inflation pressure for each tyre on each vehicle, and it is quite a good idea to have these pressures marked on, say, the wings. Pressures should be checked at least once a week, the aim being to see that they do not fall more than 5 lb. or 6 lb. below that which is correct for the tyre.

Compensation Undesirable To over-inflate in order to allow for pressure loss, or to leave the tyre under-inflated to allow for pressure increase, are both undesirable practices. Pressures should always be checked when the tyres are cold.

All tyres should be checked weekly, particular attention being paid to the following items:—Inflation pressure; cuts; erratic tread wear; tread worn smooth; misalignment wear; camber wear; incorrect twinning; general positioning; damage caused by oil, grease and contact with the kerb; tyre contact with chassis; effect of overloading.

Tyre fitters are sometimes tempted to use methods which are too drastic when endeavouring to remove a tyre which has rusted on to a rim. One of the special penetrating fluids which are sold for this purpose will prove of material assistance, but if the rims be painted with graphite paint or Tyreprim before the tyre is fitted, this rusting-on trouble will be greatly reduced.

The efficiency of any tyre maintenance service is largely dependent upon the keeping of clear and accurate records, which should be examined periodically. Not only is this a check on the maintenance work's having been carried out to schedule, but a regular analysis of such records should provide valuable information which can be used to good effect still further to decrease tyre costs.

Where the condition of a vehicle'is adversely affecting tyre performance, this fact should be brought to the Irotice of the maintenance man concerned. Suitable provision should also be made for informing the appropriate authority of any tyre faults apparently due to driving methods; in the first instance, the "appropriate authority" would he the driver himself.

There are many other things with which a tyre fitter must be well acquainted, amongst which may be mentioned the mounting and demo unting of tyres and how to repair them; how to check wheel alignment, to position tyres on a vehicle so as to obtain maximum tread life, and so on. The tyre fitter is, in fact, the key to the whole matter of tyre maintenance.

By the way, there is just a point concerning front tyre wear such as appears to affect the larger tyres as fitted to double-deck buses. The condition is that of building up in the centre, with a peculiar form of wear on the shoulder of the tyres. It is thought that the main cause is due to brake action.

It is well known, of course, that when a vehicle is braked the load is thrown forward on to the front axle in the form of a shock load. Under this, the tyres naturally deflect momentarily, the shoulders wipe the road, the centre stands proud, and lumpy wear develops.

Approaching corners and roundabouts at too high a speed can have a similar effect. The tyres have to resist the forward motion of the vehicle as the brakes are applied, as well as having to conform to a sudden change in direction.

Just a last word to operators: choose your tyres with care and fit the correct ones in the right positions for the conditions of service. Check service conditions, maintain chassis, and, more than anything else, organize a proper tyre-maintenance service. If this be done, it is certain that good dividends will be paid in reduced tyre-mile cost, in addition to which fleet reliability will bp considerably enhanced.

In the compilation of the foregoing article, the writer wishes to acknowledge the assistance given by all the tyre makers, in respect of both manuscript and illustrations. The interesting graphs were prepared by the Dunlop Rubber Co., Ltd.