THE LATEST BRITISH 25-30-CWT. CHASSIS.

Page 11

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

Full Details of the New Morris, which Embodies Servo-operated Four-wheel Brakes, a 15.9 h.p. Engine and a Two-piece Propeller Shaft.

IT HAS been known for some time that Morris Commercial Cars, Ltd., 'Foundry Lane Works, Soho, Birmingham, have been engaged in the design and production of a new commercial , chassis suitable for loads of from 25 to -30 ewt, and,in ,11 longer wheelbase, as 'a passenger-carrying vehicle. We examined one of these chassis at the British Industries Fair, at Birmingham, Where it was exhibited for the benefit of overseas buyers, arad' more recently we have inspected the chassis in detail ; at the Birmingham works of the makers, and it is now permissible to deal with it in our pages.

Our first 4repressions wore that the chassis is a sturdily built machine, designed on sound lines, and fully equal to carrying successfully over long . periods the load for which it is intended. A closer inspection convinced us that our first impressions were correct, for although the weight is by no means ex. cessive, yet it has been so distributed that the utmost advantage has been

taken of it. Take, for instance, the method of supporting the spring brackets. These are usually secured to the frame side-members and reinforced by a cross-member which stretches between. them, but, in the new Morris, this , method of construction is carried still

further, the cross-members at these points !xi:iv carried under the side members and extended so that they actually take a large part of the load, the spring brackets being riveted to the frame and also to the cross-members, the arangerecut being small, however, that the rivets do not carry the load.

, The frame side members are of deep channel-section pressed steei. with a long gradual in-sweep to the front so that a large steering lock can he provided, and a slight up-sweep to the rear, over the back axle.

The springs are almost fiat under . load and are designed to give the maximum flexibility with the proper load overloading is strongly deprecated and allowance is not made for this.

It must • ba emphasized that this chassis is not a mass-production job in the ordinary sense of the word. Not only is it built throughout at the Birmingham works, where a very large additional four-storey building has been constructed solely for its production, but each unit receives individual atten tion. Crankshafts and flywheels are most carefully balanced, the connecting rods are carefullyi sorted and tested so that the four in an engine shall not vary more than lf of an oz. apiece, and 50 :011 through every operation.

The power unit is an entirely new departure. it has a bore of 80 min, and a stroke of 125 mm., the B.A.C. ratio being 15.9, and the b.b.p. 17.5 at 1,000 r.p.m., the torque being 95 ft. lb. The reciprocating parts are light, the pistons being of aluminium with • tubular gudgeon pins baring phosphor bronze end buttons, whilst the connecting rods are of high tensile steel of a carefully designed 11 section. The stout crankshaft is mounted in three hearings of the white-metal-lined type having bronze shells, these being carried in the upper half of the crankcase, whieh is cast in one with the four cylinders.

The valves are arranged side by side, working in long guides, the Mushroomheaded tappets are operated direet by the camshaft and each is provided with a fine screw adjustment. Incidentally, the valves are ground on to their seats by an electrically driven machine giving a semi-rotary motion. The cylinder heads form a single casting which is secured by 15 studs. Spiral gears are employed for driving the camshaft, Lucas dynamo and magneto, the latter two being mounted in tandem and connected by a coupling which can be adjusted to any desired timing position.

The 12-volt Lucas starter is flangemounted on the flywheel housing and provided with a Bendix drive.

The engine lubricant is circulated by a plunger pump driven from the camshaft and supplying oil to the three crankshaft bearings and the troughs for the big-ends are so arranged that the supply is increased when ascending an incline. Special troughs pass oil to the camshaft bearings and timing gears, whilst a fine-mesh filter, easily removable for cleaning, ensures the extraction of dirt. There is a large combined oil eller and breather with a gauze strainer at the off-side of the crankcase.

In this model the water is circulated by an impeller type pump driven from the tail of the fan spindle. The fan itself has four blades and is driven by a V rubber belt.

Cooling is effected by a large-capacity radiator of the cast-aluminium headerand-bottom-tank type with a large extension tank behind the header.

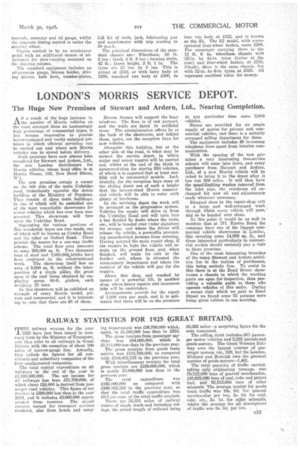

In front of the timing cover is mounted a Maxfield tyre pump with a pinion clutch which is inserted, when desired, into internal teeth cut in a plate riveted to the timing wheel which drives the dynamo.

So that the engine can rapidly gain Its most efficient working temperature after starting, there is a Thermit heating-control device, which is situated in the upper water pipe leading to the radiator. It restricts the flow of water through the radiator until the necessary degree of heat is obtained.

An interesting form of governor will be fitted in the future. This is controlled by the road speed of the vehicle, the means employed being the speedometer drive from the gearbox, which is first taken to a mechanism which closes a needle valve into the diffuser of the enrburetter when a pre-determined road speed is exceeded, the cable then being continued to drive the speedometer. This device is the invention of Mr. C. F. Lawrence King, A.M.I.A.E., the sales manager of Morris Commercial Cars, Ltd., the general manager of the company being Mr. W. Cannel.

Unit construction is employed for the engine and gearbox, which are threepoint mounted in the frame, and the drive is taken through a single-plate dry clutch having a steel spinning member split radially and gripped between two Raybestos bonded-asbestos rings, the spigot bearing being a radial ball race. Eight springs operate on the sliding member, and the system of leverage permits a comparatively light foot pressure for declutching.

Four gear ratios are provided, these being: top, direct, and the ethers 1.7-1, 2.4-1 and 3.5-1, respectively, with a reverse of 4.454. Gear changing is effected by a swinging lever carried in a gate and operating three selector forks, two of which are always effectively locked.

A skew-gear drive at the rear of the gearbox operates the governor and speedometer. All the gears have wide faces and are mounted on large diameter splined shafts kept as short as possible to prevent whip and running in ball bearings.

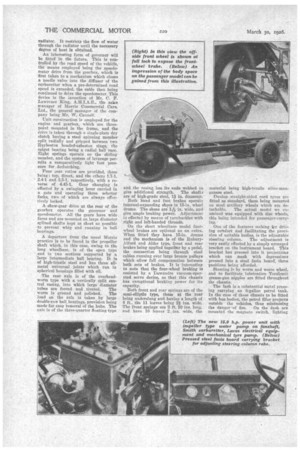

A departure from the usual Morris practice is to be found in the propeller shaft which, in this case, owing to the long wheelbase, is of the open type and in two sections supported by a large intermediate ball bearing. It is of high-tensile steel and has three allmetal universal joints which run in spherical housings filled with oil.

The rear axle is of the overheadworm type with a vertically split central easing, into which large diameter tubes are forced and riveted. The worm is ground and polished. The load on the axle is taken by large double-row ball bearings, provision being made for easy iemoval of the hubs. The axle is of the three-quarter floating type and the casing has its ends webbed to give additional strength. The shafts are of high-grade steel, 11 in. diameter.

Both hand and foot brakes operate internal-expanding shoes in 15-in, wheel drums. The shoes are 115,T in. wide, and give ample braking power. Adjustment is effectel by means of turnbuckles with right and left-handed threads.

On the short wheelbase model fourwheel brakes are optional as an extra. When fitted they have 15-in, drums and the mechanism is of the RuburyAlford and Alder type, front and rear brakes being applied together by a pedal, the connection being through steel cables running over large bronze pulleys which allow full compensation between both sets of brakes. It is interesting to note that the four-wheel braking is assisted by a Dewandre vacuum-operated servo device, so that this chassis has exceptional braking power for its capacity.

Both front and rear springs are of the semi-elliptic type, those at the rear being underslung and having a length of 4 ft., the 11 leaves being 21 ins. wide. The front springs are 2 ft. 10 ins, long, and. have 10 leaves 2 ins, wide, the

material being high-tensile silieo-manganese steel.

Dunlop straight-sided cord tyres are fitted as standard, these being mounted on steel artillery wheels which are de

tachable. The actual model we examined was equipped with disc wheels, this being intended for passenger-carrying.

One of the features making for driving comfort and facilitating the provision of suitable bodies, is the adjustable steering column. The adjustment is very easily effected by a simply arranged bracket on the instrument board. This bracket has pressed into it projections which can mesh with depressions pressed into a steel facia board, three positions being afforded.

Steering is by worm and worm wheel, and to facilitate lubrication Tecalemit grease-gun nipples are fitted throughout the chassis.

The lash is a substantial metal pressing carrying an 8-gallon petrol tank. In the case of those chassis to be fitted with bus bodies, the petrol filler projects outside the vehicles, thus minimizing the danger Jof fire. On the dash are mounted the magneto switch. lighting Controls, ammeter and qil gauge, whilst the magneto timing control is under the steerine wheel.

Engine control is by an accelerator pedal with an additional means of adjustment for slow-running. mounted on 'the steering coltiten.

The standard equipment includes an oil-pressure gauge, licence holder, driving 'mirror, bulb horn, number-plates, full kit of tools, jack, lubricating gun and speedometer with trip reading to 30 m.p.h.

The principal dimensions of the standard chassis are: Wheelbase, 10 ft. 2 ins.; track, 4 ft. 8 ins.; turning circle, 42 ft. ; frame height, 2 ft. 1 in. The tyres are 33 ins. by 5 ins. This is priced at £250, or with lorry body at £295, standard van body at £300, de luxe van body at 1315, and is known Ers the Zl. The Z2 model, with servooperated four-wheel brakes, costs £280. For -passenger carrying there is the 11 ft. 6 in. wheelbase chassis with 32-in. by 41-in. tyres (twins at the rear) and four-wheel brakes, at £285. Finally, there is the same chassis, but with 32-in, by 6-in. tyres, at £315. All represent excellent value for money.