DENNIS PRODUCTIONS IN THE MAKING,

Page 19

Page 20

If you've noticed an error in this article please click here to report it so we can fix it.

A Brief Description of the Dennis Factory, which is One of the Largest and Best Equipped in the Country.

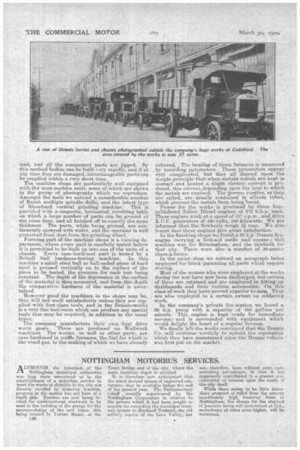

FEW PEOPLE who. travel by train from London to Guildford can fail to notice the imposing Dennis factory, situated as' it is on. a slight incline to the right of the line. It is some considerable time since we had an opportunity of viSiting the works, and we were greatly impressed with the vast increases which have been made, and the improvements which are everywhere manifest.. The works is neiv one of the largest and most up-to-date engaged in the motor industry in this country. It has the advantage of being self-contained, and as its area is in no way restricted by surrounding buildings the corn. pany has been enabled.to lay down the shops with an eye to the most efficient production.

The upper stories are confined to the offices ; it is, therefore, unnecessary to waste power and time by employing lifts for the transport of heavy parts, as has to be done in works where machines are installed on super-imposed floors and fer the same reason lighting has been facilitated, and for cleanliness, general lighting and healthy working conditions it would be difficult to find a better, or even as good, a factory.

It is seldom that a factory can be classed as a work of art, but the facade of the Dennis works, the vevtibule and the lay-out of the offices are very pleasing architecturally, and the visitor is at once impressed with the order and cleanliness with which he is met.

Ventilation has received particular attention and it is said that the whole Volume of air in the works is renewed every 20 minutes by means of the overhead ventilating pipes.

The company were particularly .forttnate in receiving large contracts almost at the commencement of hostilities, and these were maintained until the Armistice ; they are thus in. a better situation than nottny other concerns which had to change over from munition making, etc., to their pre-war tasks of manufacturing motor vehicles. The company reached a very high standard of output during the war, as many as 16 complete chassis being turned out from the works in a single day. Unfortunately, labour troubles prevented this output from being maintained after the Armistice, and at the time of our visit the output was about 40 per week, excluding the well-known Dennis fire-engines, sonic of which we saw in course of construction. In .spite of this reduction, it must not be thought, however, that work is not progres'sing-. The output is being speeded up rapidly, and even further increases are • being made in the works, which now cover something like 37 acres.

• The company obtain their own supplies of water from artesian wells. They also produce gas for we in their large case-hardening furnaces. This gas is manufactured chiefly from wood shavings and sawdust ; the light shavings and most of the sawdust are drawn from the various wood-working machines by a system of hoods and pipes, through which they are carried by suction.

The first shop which we visited is devoted to bodybuilding. Here a fine fire-engine was being finished, and quite a number of char-a-bancs bodies were in course of construction. These bodies are standard ized, and all the component parts are jigged. By this method bodies can -be built s ery rapidly, and if at any time they are damaged, interchangeable parts can. be supplied within a very short time.

The machine shops are particularly well equipped with the most-modern tools, some of which are -shown in the group of photographs which we reproduce. Amongst the tools we noticed a considerable number of Baush multiple. spindle, drills, and the latest typo of Blanchard vertical grinding machine. This is provided with a.magnetic, horizontal, revolving table on which a large number of parts can be ground at the same time, and all finished off to exactly the Same thickness. The parts, while being ground, are continuously sprayed with water, and the operator is well

protected from dust from the grinding wheel. . Forming part of the miachine shops is a, viewing department, where every part is carefully tested before it is permitted to be -built up into one of the units of a chassis. Every case-hardened part is tested by a. Brinell ball hardness-testing machine. In this machine a small steel ball or ball-ended piece of hard steel is pressed Vertically on to the surface of the piece to be tested, the pressure for each test being constant.. The depth of the depression in the surface of the material is then measured, and from this depth the comparative hardness of the material is ascertained.

However -good the machinesin the shops may he, they will not work satisfactorily unless they are supplied with first-class: tools, and in the Dennisr4vorks .a very fine tool-room which can produce any special tools that may be required, in addition to the usual type-s.

The company manufacture their own fioal drive worm gears. These are produced on Wallwork machines. The worms, as well as -other parts, are case-hardened in muffle furnaces, the fuel for which is the wood gas, to the snaking of which we have already

referred. The heating of these furnaces is measured by recercling pyrometers. These pyrometers appear very complicated, but they all -depend upon the simple principle that when certain metals are keptin contact and heated a slight electric current is produced, this ,currentdepending upon the heat to which the metals are exposed. The !lierroo. couples, as they are -called, are usually -contained in silicate tubes, . which prevent the metals from being burnt Power for the works is produced by three fourcylindered Sulzer Diesel engines of '270 b.h.p. oath. These engines work ata speed of 187 r.p.m., and drive E.C.C. generators of 450 volts, 180 kilowatts. We arc informed that the flywheels weigh 51 tons. We also learnt that these engines -give great satisfaction. In the finishing shops we found a 60 h.p. Dennis fireengine carrying a first-aid outfit and escape this machine was for Birmingham, and the thirtieth for that city. There were also .ra number of 30-seater chars-h;ban cs.

In the paint shop we noticed an aerograph being employed for black )apanning all.parts which require stoving.

Most of the women who were employed at the works during the war have now been discharged, but certain of them are retained andare employed in fitting'up dashboards and their various aceessories.• On this class of work they have proved superior tomen. They are also employed to a certain extent on soldering work.

In the company's private fire-station we found a 60 -la.p. pump with a capacity of 450 'gallons per minute. This engine is kept ready for immediate service,and is surrounded with equipment whi-ch would delight the heart of a regular fireman. We finally left the works convinced that the Dennis Co. will continue worthily to uphold thereputation which they have maintained since the Dennis vehicle 1 was first put on the market.