Big Progress in Bulk Mil

Page 82

Page 83

Page 84

Page 85

Page 86

If you've noticed an error in this article please click here to report it so we can fix it.

1,ollection

by P. A. C. Brockington,

A.M.I.Mech.E.

WHILST relatively few of the milk tankers seen on the roads today are engaged in the bulk collection of milk from farms, the development of this form of transport is potentially of greater importance to the vehicle industry than the use of tankers for trunking runs, as from country milk collection centres and creameries to town dairies. Although the trunk-running vehicles now represent the great majority of milk tankers in service, rapid progress in bulk collection gives promise that vehicles associated with this development will outnumber trunking tankers in the not too distant future.

According to official records of the Milk Marketing Board, the number of farms holding tanks in England and Wales has increased from less than 10 six years ago to over 370, and the amount of milk collected by road tanker has increased proportionately to a total of 60,000 gal. a day. Moreover, immediate plans for expansion are based on an increase in bulk collection of four times the current gallonage. Important developments in this form of milk transport are expected for the near future.

Information received from Mr. J. G. Inglis, general manager of the Scottish Milk Marketing Board, shows that schemes are operating in 12 Scottish counties, which involve the collection of 29 million gallons of milk a year, representing over 15 per cent, of the total supply. A further 7 per cent, is produced by farmers to whom holding tanks will be supplied in the near future, and it is anticipated that over 20 per cent, of the milk produced will be carried by bulk tanker within six months or so.

Providing bulk collection vehicles with suitable equipment poses many interesting design problems. In any review of D16 bulk-milk transport it is, therefore, appropriate to concentrate on measures that are being taken to cater specifically for this traffic. Tankers employed on depot-to-dairy trunking routes are of relatively simple design, the milk being normally loaded by gravity and unloaded by the same means, or with the aid of static pumping equipment.

Bulk milk collection is an all-important and possibly unique example of the way in which control by a Producers' Board is exercised to the benefit of both the vehicle operator and the equipment designer, as well as the producer and customer.

All milk produced in this country is purchased by the M.M.B. (or the Scottish or Northern Ireland Milk Marketing Boards) and transport from farm to dairy, or from farm to collection depot, is undertaken by Board vehicles or vehicle operators under contract to the Board. Rates are negotiated on a formula basis decided by a . joint committee of the

M.M.B. and the Road Haulage Association on which Clicensed operators are also represented.

All bulk schemes are organized in zones by the M.M.B. and vehicle operators collect milk from farms approved by the Board. The producer is paid an additional Id. per gallon for milk collected in bulk for a period of years, related to the size of the storage tank, and at the end of this period he receives a continuing premium of d. per gallon. These payments represent a subsidy by which the relatively high cost of the refrigerated holding tank can be recovered by the farmer in the prescribed period, and which subsequently offers a higher profit incentive.

The farmer is immediately offered a means of reducing labour costs on the farm if he exploits the advantages of the scheme to the full. These include the elimination of churn handling, including churn cleaning, and the facility with which the system can be adapted to the latest milking echrriques. Savings in labour and space are also provided

at the dairy, and obviating the noise created by churn handling may be a boon in both cases.

To the vehicle operator bulk collection initially represents a normal business hazard" in that profit making is dependent upon efficient development of the scheme, with particular regard to arranging collections from farms with the minimum of waste running. In this he has the active support and expert advice of the Board, who operate a fleet of 500 vehicles, a large proportion of which are tankers. Technicians of the Board are continually experimenting with new types of vehicle equipment (often in close co-operation with the National Institute of Research in Dairying) and, in effect, provide a free consultation service to both vehicle operator and equipment maker.

Holding tanks are built to rigid specifications laid down by the Board to ensure hygiene and accuracy of measurement, and the wide knowledge and experience of the Board's technicians virtually gives them authority to stipulate the type of vehicle equipment to be used in certain cases. Equipment makers have, however, a large measure of freedom in developing special features.

Holding-tank Design The development of advanced types of tanker equipment is, in part, related to holding-tank design in that a means of accurately measuring the milk intake by a vehiclemounted instrument could give valuable latitude with regard to the specification of the farm tank. Looking into the more distant future it is possible that a flowmeter may be evolved which could be incorporated in the vehicle equipment, and which would afford sufficient accuracy to obviate the use of calibrated holding tanks and measurement by dipstick. Although this project is unlikely to materialize for some time, the prospect has fostered the development of the vacuum-filling system. It is considered that a flowmeter could be more readily employed in conjunction with a vacuum system than with a mechanicallydriven-pump type.

Vacuum filling is being used experimentally by the Board and will be employed in service by a number of hauliers D17 before the end of the year. Essential features of the system include an exhauster driven by a battery-operated electric motor, which creates a vacuum in the tank, the milk being drawn through an extension of the intake pipe at the top of the tank. Although sufficient vacuum to provide a high rate of filling cannot be immediately created by the exhauster, operation of the unit during the run builds up the vacuum and enables the tank to be filled at the normal rate at the farm.

Apart from the possibility of installing a flowmeter in a system of this type, it has many other advantages, which include freedom from noxious fumes during collection, engines being switched off when the tank is being filled. Also, the milk can be drained from the pipes without loss, which is of importance if mixing of two or more grades of milk has to he avoided.

Electrically driven pumps, energized by the vehicle battery are also available, both types of system necessitating the use of a high-capacity alkaline battery and a 51-in. generator. Although lack of space precludes a detailed description of the tanker-driver's duties at the farm and at the dairy, it should be emphasized that his training and qualifications give him the status of a specialist. An exact procedure is outlined in his instructions regarding dipstick measurement, temperature checking, sample preparation and so on, and high standards of cleanliness must be observed. If these instructions are not closely followed. the effect on the quality of milk may lead to rejection of the entire load by the dairy.

New Midlands Scheme

One of the latest schemes to be introduced by the M.M.B. was inaugurated on October 1, 1960, in the East Midland Region of the Board, which covers the counties of Warwick, Leicester, Nottingham, Northampton, Bedford and Rutland. Bulk-milk collection in this area possibly has a greater potential than that of any other district because the centres of high population density are favourably located in respect to sources of supply, and runs can be planned economically. Two hauliers are currently engaged in this scheme, bulk supplies being delivered to the Aston Cross dairy of Midland Counties Dairy, Ltd., in Birmingham. On September 1 Birmingham Co-operative Society, Ltd., will officially commence a bulk collection scheme.

Starting operations on October 1, with a milk tanker loaned by the M.M.B., C. Blake and Son of Loxley, some three miles south of Stratford-on-Avon, collected 602 gallons from six farms on the first day, and on December 1 a total of 1,623 gallons was collected in a company vehicle from 11 farms in one trip. The concern now operates two vehicles, each with a capacity of 1,750 gallons.

Eighteen Farms Visited

One tan.ker recently collected 1,276 gallons on a nightcollection run of 47 miles, whilst the following day an additional load of 1,482 gallons was collected and delivered to the dairy, the total mileage covered in 24 hr. being 173. Eighteen farms were visited, and the total operating time of the two drivers was 124 hours. On the same day the second vehicle collected 1,176 gal. of milk from 10 farms in one trip of 101 miles.

When this article was prepared some weeks ago collections were being made from 34 farms in a radius of about 16 miles. Progress is so rapid, however, that the total now probably exceeds this number by an appreciable margin.

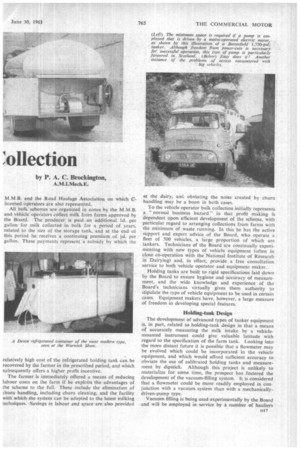

Both vehicles are based on Dodge 7-8-ton chassis powered by Leyland 0.375 diesels and equipped with a David Brown five-speed gearbox and an Eaton two-speed back axle. The Darham stainless-steel tank is of two compartments, and pumping equipment comprises a positive-displacement stainless-steel pump driven through a centrifugal clutch from the power take-off, an engine throttle control being fitted in the rear compartment. Pumping rate is about 5,000 gal. per hr., and the system of interconnected pipes enables the pump to be used for discharge as well as filling.

A measure of the potential of the bulk collection by tanker compared with churn collection is the estimate given by a member of the company that eventually, with greater concentration of farms, two bulk tankers will do the work of five churn-carrying lorries. The Blake company have been operating churn-carrying lorries for well over 30 years, the total fleet now numbering 16 vehicles. These are mainly Bedford lorries of 5-ton to 7-ton capacity, and on average 1,000-1,500 gallons are collected daily with the use of about 110 churns.

Due for delivery in a few months' time, a Darham threecompartment tanker based on a Four-in-Line articulated trailer probably represents the most advanced form of bulk collection • to be introduced since its inception. This will be hauled by a Dodge tractor and will have a capacity of 2,500 gallons, a compartment of 500 gallons being located above the tractor chassis on a stepped-extension of the trailer. A vacuum-filling system is employed of the type mentioned, fitted with an electrically operated cut-out device to prevent overflow when the tank is full. It is anticipated that the articulated outfit manned by an experienced driver will afford greater manceuvrability on tcrtuous farm access roads.

Pilot Scheme in Surrey

Articulated outfits of three compartments with similar capacity will also be used in an M.M.B. pilot scheme in the Surrey area. Six of these trailers will be hauled by Albion Clydesdale tractors and will be run in conjunction with rigid vehicles having a tank capacity of 1,750 gal. to obtain direct comparisons of effective load-carrying capability, operating cost and manceuvrability. Because of their increased capacity, the articulated tankers will be mainly employed for collections from farms involving relatively long-distance deliveries. A special feature of the Andrew Bros. tanker employed by W. Freeman and Sons, South Yardley, Birmingham, is the use of hydrostatic drive for the stainless-steel positivedisplacement milk pump. The tank is of the two-compartment type with a capacity of 1,750 gal. and is mounted on a Dodge forward-control chassis equipped with a Leyland 0.350 power unit, a David Brown five-speed gearbox, Eaton two-speed axle and power-ass:sted steering.

Variable-speed Motor

Operated by a short propeller shaft from the gearbox power take-off, a hydraulic pump supplies fluid to a reversible variable-speed motor located forward of the rear compartment, which drives the shaft of the milk pump by twin belts. Clutching-in and reversing are performed hydraulically, the ease with which the drive can be reversed being an important potential advantage in that it would obviate complications if it were necessary to use the pump for emptying the tanker on the road in the event of an emergency. The speed of the pump can be matched exactly to the low-speed torque characteristics of the vehicle engine, and in effect this reduces the operating speed of the unit. It is emphasized by the tanker makers that a more flexible control over pump speeds is obtainable than is possible with a mechanical drive from the p.t.-o. Maximum output of the pump is 5,000 g.p.h.

The tank is insulated with 2 in. of Isoflex material and is panelled in polished aluminium, lack of paint obviating attack by milk oxide in the event of spillage. Scotchlite lettering is used on the name panel to give self-illumination at night, whilst the bodywork livery is in coffee and cream.

Collecting milk in an area to the east and north-east of the city (which includes the centres of Sutton Coldfield, Tamworth, Market Bosworth, Fillongley and Maxstoke), the tanker started operation on December 1, 1960, and by the end of the month, running one trip a day, had handled a total of 11,799 gallons. By April 30, the monthly total had increased to 46,897, and on May 8 collections from 12 farms in one trip of 120 miles followed by a second trip of 30 miles raised the total gallons carried in 24 hr. to the record figure of 2,300. On average the current fuel consumption is 134 m.p.g.

A second vehicle was added to the fleet later in May but as yet no statistics are available showing the expansion in

traffic since that date. It is probable that the number of farms in the collection area now exceeds 20.

Bulk milk collection for the Birmingham Co-operative Society, Ltd., will be performed with an Andrews Bros. tanker of the same capacity fitted with a vacuum-filling system. Equipment will include' a Reavell exhauster driven by a C.A.V. 24-v. electric motor which can provide a vacuum of 17 in. of mercury. This will afford a rate of milk flow of over 5,000 g.ti.h. at the farm with the engine switched off, full vacuum being created when the vehicle is travelling on the road.

Over-filling is prevented by means of an interceptor vessel, situated between the tank and the exhauster, which is fitted with an electronic probe. This is sensitive to liquid, and if the milk attains too high a level in the tank the probe immediately actuates a valve which stops the flow of milk by opening a vent to atmosphere.

Long-standing Hauliers

Milk hauliers of long standing, the Freeman company, operate 25 platform vehicles, .12 of which are engaged in churn collection. These are Thames 5-tonners and are also used for the transport of brewers' grains for feeding cattle.

Both the Blake and Freeman companies have a portable pumping set to empty the contents of a holding tank into churns if the milk is unacceptable for transport by tanker. The motive unit of these sets is a small air-cooled petrol engine which drives a stainless-steel pump.

Time for discharge at the dairy, tank cleansing and so on averages about 1 hr. 20 min., the driver being responsible for breaking the seals of the manholes and so on.

Commenting on the type of loading equipment employed in Scotland, Mr. Inglis observes that mains-operated electrically driven pumps are in general use, but that a minority of operators are trying out the battery-driven type. It appears that this method may offer some advantages, despite the fact that practically no trouble has been experienced in the past seven years with mains-driven pumps as a result of failure of the farm supply.

With regard to production of a satisfactory flowmeter, Mr. Inglis states that its advent is eagerly awaited by the majority of operators in Scotland. The considerable number of small dairy men in Scotland would welcome the facility to receive milk from a tanker in the required quantity, and this is not practicable unless an accurate flowmeter is fitted. The fact that a flowmeter would obviate the need for holding-tank rigidity would, it is considered, inevitably result in a saving in capitaloutlay. In contrast to the claims of the Scottish Milk Marketing Board, the Butterfield company refer to the relatively high incidence of power cuts in some rural areas in England and Wales, and emphasize that this is prejudicial to the use of electrically operated pumps deriving power from the mains supply. It is also pointed out that recent advances in the development of alternating-current engine-driven generators could be favourable to the use of battery-operated electrically driven pump systems, the motors of which are reversible.

In an outline of milk-tanker features, the A.P.V. company state that the tank is normally constructed of stainless steel of approximately 10 gauge and is insulated with about 2 in. of glass-fibre, polystyrene or equivalent material. This company produces stainless-steel storage tanks and pipe fittings as well as a stainless-steel centrifugal pump, known as the Puma.

In the case of the Mickleover transport company, vehicle tanks are available with outer cladding and ends of colourimpregnated reinforced plastics material, which has favourable thermal-insulation properties and is immune from corrosion. The insulating material employed is normally expanded polystyrene with a thickness of I in.