DEVELOPING LIGHT FIRE-FIGHTING EQUIPMENT.

Page 9

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

A New British Entrant Into the Fields of Fire-engine and Goods Vehicle Manufacture. First Published Details of the Martin 250-300-gallon Fire Pump and 30-cwt. Chassis.

A PROMISING and highly efficient

fire-engine of 250-300 gallons per minute capacity has recently been produced by Martin's Cultivator Co., Ltd., of Lincolnshire Iron Works, Stamford, who are also marketing the same chassis as that used for the engine, but, of course, in a slightly modified form, for the carrying of 30-cwt. loads, either in the form of passengers or goods. This is the first time that the company have entered into the field of road transport, but they have for long been known in connection with many ingenious and practicable agricultural appliances and for their neat and effective trailer pumps, the Capacity of these ranging from 150-200 gallons per minute to 250-300 gallons.

The patent positive-action valveless pump, which is employed on these trailer pumps, and now on the new fireengine, is a really remarkable product, being extraordinarily simple and yet callable of working for many hours at a stretch without any sign of failure, and giving a steady supply of water at a high pressure. As an example of what this pump can do, it may be of interest to refer to an incident which occurred in the autumn of last year. At that time a number of stacks of hey caught fire in the village of Tickencote, near Stamford ; as quickly as possible a Martin trailer pump was drawn to the scene and 850,000 gallons of water were forced up a steep incline through 2,000 feet of hose, three Y pieces ansi five branches in 19i hours, on a petrol con

sumption of 39 gallons, with the result that the fire was prevented from spreading and the village saved.

As will be seen from our illustrations, the new Martin engine presents a very attractive appearance. The power unit is a four-cylinder Dorman of 100 mm. bore and 140 mm, stroke, developilig 45 b.h.p. at 1,600 r.p.m. The cylinders are of the L-headed type and are cast en bloc, the valve gear being enclosed by a single cover plate.

To provide easy starting without the need of a self-starter, the engine has Bosch dual ignition, the magneto being driven through a Simms vernier coupling. For providing current for lighting purposes a Lucas dynamo is mounted on a cast bracket, which also forms a casing for the silent chain by which it is driven from the timing gear.

The fan is carried on aft eccentric spindle to afford a means of adjustment, and there is a separate impeller-type water pump, both this and the fan being driven by link-type leather belts. Carburation is attended to by a Zenith instrument.

The gearbox, which is bolted up as a unit with the engine, is a Martin product, both engine and gearbox being secured at four main points to a threepaint-suspended sub-frame with a swivel bearing aethe front end. Further to strengthen the gearbox, this is supported on the sub-frame by two brackets bolted to the clutch housing. Incidentally the clutch is a Ferodo-faced cone.

The gearbox is fitted throughout with ball bearings and is centrally controlled ; it affords the following ratios :—First, 5.27 to 1; second, 2.61 to 1; third, 1.58 to 1; fourth, direct ; reverse, 8.23 to 1. The final drive ratio is 6.5 to 1, and at 1,500 r.p.m. of the engine the equivalent road speeds are 4.5 m.p.h., 9.25 m.p.h., 15.18 m.p.h., 24 m.p.h., and reverse 2.9 m.p.h. It is well to point out here that the rear wheels are fitted with 870 mm.

• by 100 mm. 'cushion tyres of Goodrich make carried on steel-disc wheels. Tyres the same size are employed on the front wheels, but those at the rear are -twins and those at the front singles.

Behind the gearbox is a single-piece propeller shaft, with two universal joints of the jaw-and-pin type, provided with phosphor-bronze bushes, and each totally enclosed by two aluminium covers, having between them a sleeve of leather secured by wire, a fitting for a grease gun being provided. This is an excellent feature which should give the universal joints an exceptionally long life, and must remove what is a constant source of anxiety on some,. vehicles.

The rear axle, which is of Kirkstall make, is of the pot type with an overhead worm. Both hand and foot brakes operate in the rear-wheel drums and are compensated, the shoes being of the duplex opposed type, in which each pair of shoes occupies slightly under half of the total drum area, whilst being of full drum width. The brake rods are provided with turnbuckle adjusters, these being single-threaded with locking hand nuts. , . Steering is effected through a gear of the worm and opposed split-nut type, which has the advantage that the gear is balanced and the leverage increases with the lock. A spriug fender protects the radiator, and, in fact, the whole front of the machine.

Pressed-steel channels are used for the frame, these have a depth of 5 ins., are tapered to the front and swept down to the dumb-irons. There is a neat scuttle dash of pressed steel carried on an angle-iron frame.

Cooling of the water is effected by a radiator of the gilled vertical-tube pattern with a cast-aluminium header and bottom tank, but while the fire pump is in operation some of the water supplied by it is by-passed through the engine cylinders, and there is a one-inch overflow pipe, the water from which is conducted away from the vicinity of the fire-engine by means of a length of hose. This is an important point, as it prevents bogging the wheels on ground which might be softened unduly by the water.

An oval-shaped petrol tank is carried on the dash and supplies the carburetter by gravity. It holds ten gallons and has a two-way cock which gives a re serve supply of two gallons. Chassis lubrication is by the grease-gun system throughout.

The main dimensions are :—Wheelbase, 10 ft. 6 ins.; track, 4 ft. 10i ins. The body is built of seasoned wood and arranged to carry 2,000 ft. of hose in the central box. At the back of this box there is a 25-gallon emergency water tank. Accommodation is provided for 14 men in all-8 on the box, 2 on the driver's seat, 2 on the engineer's platform and 2 on the running boards.

During a test run we easily attained speeds of 40 m.p.h. on the level and turned sharp corners in narrow lanes, without slip or rolling, at 25 m.p.h.

The equipment includes two Minimax Frowave two-gallon chemical extinguishers, two Minim ax Auto hand pumps for petrol fires, a first-aid ambulance box for 50 persons, for dealing with burns and injuries, a 30-ft. telescopic ladder and 120 ft. of emergency hose, fitted with a I-in. nozzle, for using In connection with the emergency supply of water. The last-named device proves extremely useful for fires where old beams, etc.,. are smouldering and where a lot of water will, possibly, do more damage than a fire.

We will now deal more fully with the pump, which is perhaps the most inc26

teresting part of the machine. It is

constructed of phosphor-bronze, gunmetal and stainless steel. It has copper air vessels, draincocks, and an adjustable spring-loaded relief valve by which emcees water can be taken back to the input, thus preventing the bursting of the hose if this be run over.

The pump is positive acting, and no priming whatever is required. There is a small air vessel on the suction side for balancing the pull, and a larger air vessel, against which the pump works, to assist in balancing the delivery by absorbing any slight pulsations which may occur. Running at 600 r.p.m., there are 1,200 delivery strokes per minute, so that the pulsations, if any, should certainly be of a very minor order.

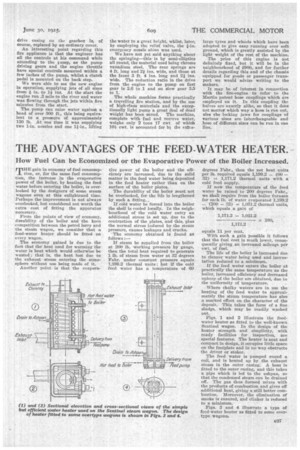

The pump consists of a casing of large bare, with inlet and outlet ports at its base. Passing through the centre of this, and carried in end plates, is the pump-driving spindle, on which is keyed a rotor, formed in one with which are two eccentrics. Mounted on these eccentrics are circular rockers or pistons, considerably smaller in diameter than the cylinder, stainless steel floating bushes being interposed.

These circular pistons do not quite touch the outer casing, but the clearance is only .002 in. At the bottom of each ie a stainless-steel slide, The upper end of which is rounded and slipped from the side into a similarly shaped channel in the piston. It is this slide which prevents the piston from rotating, the latter merely travels up and down, at the same time rocking to and fro, so that at no portion of its travel does it leave the inner surface of the outer casing, except for the slight clearance to which we have already referred.

The design of the pump can easily be seen from the drawings which we repro

duce. The water is drawn in at one side of the slide and is forced right round the inside of the casing until it reaches the outlet port. So effective is the pump that when it was quite dry tests showed that a vacuum of between 28 ins. and 30 ins, of mercury could easily be obtained at the suction side. To provide good balance and an even pressure, the eccentrics on the rotor are separated by 180 degrees, and there is a central diaphragm which fits the bore and divides the cylinder into two cornpartinents, so giving two suction and two delivery strokes per revolution.

The design we illustrate, and which is equipped with a piston lubricator, has been supplanted by another pattern in which two separate lubricators are provided, these being of the oil-gun type and supplying each piston independently. The drive to the pump is effected by replacing the ordinary cover of the gearbox by a casing containing a two-speed gear. from which the drive is conveyed by a cardan shaft with universal joints, of the type already described, to the pump. The shaft runs through a tube in the bottom of the hose box. When it is desired to use the chassis for passenger or goods work, the fire-pump

drive casing on the gearbox is, of course, replaced by an ordinary cover.

An interesting point regarding this fire appliance is that the engineer has all the controls at his command while attending to the 1.,ump, as the pump driving gears and the engine throttle have special controls mounted within a few inches of the pump, whilst a clutch pedal is mounted on the back step. We were able to see the new engine in operation, supplying jets of all sizes from in. to 1i ins. At the start the engine ran .3 mile to the river and water was flowing through the jets within five minutes from the start.

The pump can raise water against a head of over 300 ft., this being equivalent to a pressure of approximately 130 lb. At one time it was supplying two 1-in, nozzles and one 11-in., lifting

the water to a great height, whilst, later, by employing the relief valve, the 1-in. emergency nozzle alone was used.

We have not yet said anything about the springing—this is by semi-elliptics all round, the material used being chrome vanadium steel. The rear springs are 4 ft. long and 21 ins, wide, and those at the front 3 ft. 4 ins, long and 21 ins. wide. The reduction ratio in the drive from the engine to the pump on fast gear is 2.6 to 1 and on slow gear 3.5 to 1.

The whole machine forms practically a travelling fire station, and by the use of high-class materials and the exceptionally light pump a great deal of dead weight has been saved. The machine, complete with fuel and reenve water, weighs only 2 tons 17 cwt of which 10icwt. is accounted for b3 the exam

large tyres and wheels which have been adopted to give easy running over soft ground, which is greatly assisted by the light weight of the rest of the machine.

The price of this engine is not definitely fixed, but it will be in the neighbourhood of £900, and for further details regarding this and of the chassis equipped for goods or passenger transport we would advise writing to the makers.

It may be of interest in connection with the fire-engine to refer to the Martin patent hose couplings which are employed on it. In this coupling the halves are exactly alike, so that it does not matter which way a hose is run out, also the locking jaws for couplings of various sizes are interchangeable and hose of different sizes can be run in one line.