11111 Tyre Developments

Page 48

Page 49

Page 50

If you've noticed an error in this article please click here to report it so we can fix it.

Keep Pace

By A. J. P. Wilding,

A M I Mech E, IV1 1 R TE ASTUDY of back issues of the "Tables of Operating Costs" published annually by "The Commercial Motor" shows that the proportion of vehicle running costs applicable to tyres is not much different today from what it was at the beginning of the 1939-45 war. Taking a maximum-gross four-wheeler as an example, tyres accounted for 13.3 per cent of running costs in 1940 and in 1965 the figure is 14-8 per cent. And this despite the fact that the 1940 vehicle carried a payload of 7-8 tons to gross the then-permitted maximum of 12 tons whilst its 1965 counterpart can gross 16 tons with a payload of around 11 tons.

What must also be taken into account is the increase in speed limits between the two dates: from 20 m.p.h. in 1940 to 40 m.p.h. now. Admittedly, the 20 m.p.h. limit will rarely have been observed by drivers but then speeds even higher than 40 m.p.h. are possible now on motorways, There is further interest in the "Tables of Operating Costs" over the years (and it should be pointed out here that these figures are based on facts obtained from actual operating experience). Keeping to the maximum-gross fourwheeler for example, just after the war tyre costs were 18.5 per cent of total running costs, in 1957 the figure had gone down" to 16.8 per cent and in 1961 this trend was maintained, with a further slight reduction to 16.7 per cent.

The indication from all this is that tyre developments over the past 25 years have kept pace with constantly rising costs and increased pressure of operation, for the changes in maximum weight and speed limit legislation have put a considerable extra burden on vehicles' tyre equipment. Improved Maintenance techniques will also have played a big part in keeping tyre costs down, and while tyre mileages of around 35,000 were considered exCellent prior to the war, by 1950 50,000mile averages were common and now mileages of around 75,000 miles with textiles and over 100,000 with steel cord tyres are not uncommon in fleets that have good tyre-maintenance systems—and where continuous high speeds are not the rule.

The improvements that have taken place in tyre design to bring about what must be accepted as a very

favourable situation have been directed at the rubber compounds used for the tread and other parts of tyres and also the casing construction. The main factors in tyre design are tread life; radial Of cross-bias casing construction; steel or textile casing; safety; and driver comfort. Tread life and safety are in fact linked, for it would be possible to use compounds which would give remarkable mileages but would be dangerous to use because of lack of grip on the road for braking and directional control. Wear in a tread is not only a function of sideways movement of the tyre on the road, because when rolling in a straight path there is a "

shuffling" action at the tread as one portion comes into contact with the road surface and then leaves it.

Ribs, Notches—and Heat

To get improved tread life for onhighway use tyres have circumferential ribs and to improve road-holding and make for more fore-and-aft grip and better braking, notches and knife cuts are incorporated, One of the biggest factors in tread life is heat, not only ambient temperatures—in hot countries tyres wear at a fantastic rate —but also the heat generated by the tyre itself by the constant flexing of the side walls and the tread area. For this reason ribs are designed to promote cooler running and different compounds are used for the tread and for the shoulders. Tread depth is important also: a too-deep tread causes more scuffing and a faster rate of wear so it is not just a question of increasing the amount of rubber on the tyre. Tyres designed for buses are thicker in the tread than those for goods vehicles and there is also more rubber between the tread and the casing to allow for recutting. But with more rubber the result is that more fuel is used by the vehicle arid an optimum has to be

obtained; this can be -worked out by formulas

"Cling" for Commer'cials So far there has been no move to

"cling --rubber (also called lowresilience and high-hysteresis) for tread compounds in commercialvehicle tyres as there has been in car sizes. But Dunlop has been doing a lot of work on this type of tyre for commercials and will soon be announcing the introduction of these to the UK market. Here again, because the grip of the tyre on the road is increased, there is, a tendency for the vehicles' fuel consumption to suffer and also tyre mileage, but Dunlop states that by careful design, tread mileage and consumption have been .retained at the figure expected of conventional-rubber tyres.

In spite of the advantages claimed for low:resilience4read tyres, all tyre makers are not convinced that it is the full answer to problems of grip. On some surfaces the advantages are not the same as on others and the results of recent tests by a. research organization show that against a 25 per cent increase in grip on dry surfaces (where there was adequate grip anyway), on a wet road there was only a marginal improvement generally and in one case a 3 tser cent reduction in grip on one particular surface of smooth asphalt.

In trying to obtain the best life from a lyre it is important to keep the loads and inflation pressures right. The loads specified by lyre makers are not the maximarn that the lyres can carry bat the rTiasimurn at which. it is economic to run I he tyres; overall mileage depends on use, and overloading will lessen the hie.

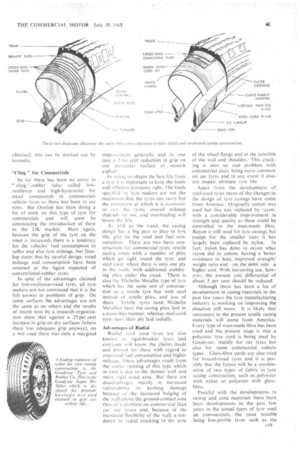

As vosli as the tread, the casing design has a big part to play in tyre life, grip on the road and fuel consumption. There are two basic constructions for commercial tyres: textile casing cords with a number of plies which go right round the tyre; and steel cord, where there is only one ply in the walls, with additional stabilizing plies under the tread. There is also the Michelin Metallic type of tyre which has the same sort of construction as a textile tyre but with steel instead of textile plies, and less of them. Textile tyres (and Michelin Metallic) have the casing plies laid in a cross-bias manner, whereas steel-cord

tyres have their ply laid radially. .

Advantages of Radial

Radial steel cord tyres are also known AS rigid-breaker tyres and everyone will know the claims made and proved for these with regard to improved fuel consumption and higher mileage. These advantages result from the cooler running of this type which in turn is due to the thinner wall and more ritlid tread area. But there are disadvantagos, mainly in increased vulnerability to kerbing damage because of the increased bulging of the wall above the ground-contact area (less oi a problem on commercial than car size tyres) and, because of the increased flexibility of the wall, a tendency to radial cracking in the area

of the wheel flange and at the junction of the wall and shoulder. This cracking is also no real problem with commercial sizes, being more common on car tyres and in any event it does not impair ultimate tyre life.

Apart from the development of steel-cord tyres many of the changes in the design of tyre casings have conic from America. Originally cotton was used but this was replaced by rayon, with a considerable improvement. in strength and quality as these could be controlled in the man-madefibre.' Rayon is still used for tyre casings but except for the smaller sizes it has

largely been replaced by nylon. in fact, nylon has done to rayon what rayon did to cotton, having a better resistance to heat, improved strength,' weight ratio and -on the debit side--a higher cost. With increasing use, however, lhe present cost differential: of about 5 per cent should be reduced.

• Although there has been .a lot of development in casing materials in the past few years the tyre manufacturing industry is working on improving the situation still more. It is likely that successors to the present textile casing materials will come from America. Every type of man-made fibre has been tried and the present stage is that a polyester tyre cord is being used by Goodyear, mainly for .eals tyres but also for some commercial--: vehicle types. Glass-fib-re cords are also tried for braced-tread tyresand -it is possible that the future will be a'conribinatiort of two types of fabric in "tyre casing construction, such as .polyester -with nylon or polyester withglass fibre,

• Parallel with the developments in casing and cord materials there have been developments in the past few years in the actual types of lyre used on commercials, the most notable being low-profile tyres such as the

Goodyear Super Single and Firestone Duplex. Since their introduction at the 1962 Commercial Motor Show low-profile tyres have had some impact on the British market and more and more are now seen on goods vehicles. Goodyear say that 1,000 Super Single tyres and wheels have been sold in the past year, and this in spite of relatively high cost due to the tyres being imported— with 40 per cent duty — from the US. Within the next two or three months Goodyear expects to be producing these tyres in the UK, and Firestone should be producing the Duplex here by the end of this year. If, as I understand, these tyres are the same price as a pair of single tyres, the use of low-profiles should increase.

The main advantage of low-profiles is a reduction in weight and when replacing twins on a tandem-axle bogie there is a saving of 5 cwt. This is also better brake-drum exposure and-important on many types of operation —tyre damage due to the trapping of brick bats and the like between a pair of twins is avoided. Improved traction on mud is often claimed but this is debatable as the wedging action of twin tyres on mud is lost. But there is the important point that less material is taken from a site onto roads and this can be a significant consideration on some types of work.

Another fairly new development in commercial-size tyres is the introduction of tubeless varieties. There is a weight saving with these also and an improvement in that fewer punctures will be experienced. The biggest cause of blow-outs is tube failure-the tyre may not fail due to heat but the tube can do so quite easily. The introduction of tubeless for commercials has been hampered largely because suitable wheels have not been available. Michelin offer a 22-5 in. tubeless tyre and this is designed for use with a single-piece well-type wheel. The well in the wheel is necessary for fitting the tyre and the size is increased from 20 in. to 22.5 in. to allow the well to be incorporated without reducing the inside diameter of the wheel and therefore limiting the size of brake-drum on the vehicle.

Here again the situation is likely to change in the fairly near future as a new design of three-piece wheel with efficient sealing of the detachable rim for use with tubeless tyres is due to go into volume production in October with most British wheel makers. The wheel. is of American origin, being to a design by the US Goodyear company and has the secondary advantage that it is very accurately made and will reduce the difficulties of balancing commercial vehicle wheels. and tyres, 1() a practice which is becoming more common with high-speed running.

The wheel can naturally be used with tyres, tubes and flaps if desired, as well as with tubeless types, and it is likely that when this wheel becomes available it will trigger off a wider use of tubeless tyres in Britain. Tyre

manufacturers will have no difficulty in offering these tyres quickly; it is simply a matter of incorporating a sealed inner face into existing designs, so they could be available immedately. There will be no trouble in performance, as tests have been carried Out for about four years.

BUYERS' GUIDE TO TYRES

Maker Details of Tyres Offered: Avon Rubber Co. Ltd., Melksham, Wits. Sizes up to 12.00-20, 18-ply with textile casings and up to 11.00-20 radial steel cord. Tread patterns suitable for general haulage, off-the-road use and on/off-road operation in textile types; general haulage only for radial cord tyres.

Sizes up to 9.00-20, 14-ply and 40x8, 12-ply textile and 11-00--20, 16-ply cross-ply steel cord. Tread patterns for general haulage and on/off-road use in textile and general haulage and off-the-road use with steel-cord construction,

Bergougnan Tyre Co. Ltd., 95-100 White Lion Street, Islington, London, N1 John Bull Rubber Co. Ltd.t Alfington House, 136 Victoria Street, London, SW1

Davis Tyre Co. Ltd., PO Box S, Inchinnan, Renfrew, Scotland Dunlop Rubber Co. Ltd., Fort Dunlop, Erdington, Birmingham Firestone Tyre and Rubber Co. Ltd., Brentford, Middx.

Fisk Tyres Ltd., Frederick Street, Riddings, Derbys. Sizes up to 10-00-20, 16-ply textile and 9-00-20 radial steel cord. Tread patterns for general haulage and oroff-road use.

This company is part of India Tyres Ltd. and operates from the same address. Sizes up to 10-00-20, 14-ply textile; no radial-steel cord tyres. Tread patterns for general haulage, off-the-road and on/off-road use.

All sizes of tyres made—up to 16.00-20, 24-ply and 14.00-24, 22-ply textile and 11-00-20 radial-steel cord. Tread patterns to suit every type of operation.

Sizes up to 1500-20, 20-ply textile and 10.00-20 radial steel cord. Also Duplex low-profile textile tyres up to 19.S-19.5. Tread patterns to suit all types of operation.

This company is part of The Kenning Motor GroupSizes up to 10.00-20, 14-ply textile. No radial-steel cord but two models have steel stabilizing plys under tread, Tread patterns suitable for general haulage and on/off-road use.

The Goodyear Tyre and Sizes up to 15-00-20, 12-ply textile and 11-00-20 Rubber Co. (Great Britain) Ltd. radial-steel cord. Also Super Single low-profile Wolverhampton textile type up to 19.5-19-5. Tread patterns to suit Henley's Tyre and Rubber Co. Ltd., Henley's House, Randolph Avenue, Maida Vale, London, W9 India Tyres Ltd.

PO Box 5, Inchinnan, Renfrew, Scotland Kelly Springfield Tyre Co.,

1-3 Redhill Street, London, N'1'/1

Michelin Tyre Co. Ltd., Stoke upon Trent, Staffs.

Nolth British Rubber Co., Ltd. Castle Mills, Edinburgh (US Royal Tyres) Pirelli Ltd., 343-345 Euston Road, London, NW1 Trelleborg Rubber Ltd., 4 Lloyd's Avenue, London, EC3 Warco Ltd., Burton Street, Peterborough, Northants. all types of operation, general haulage and on/off-road use only for Super Singles.

Sizes up to 10.00-20, 16-ply textile, no radial-steel cord tyres. Tread patterns for general haulage and on/off-road use.

Sizes up to 14.00-20, 22-ply and 9.00-24, 14-ply textile and 11.00-20 radial-steel cord. Tread patterns suitable for all types of operation.

Sizes up to 12-00--20. 18-ply textile, no radial-steel cord. Tread patterns suitable for general haulage and on/off-road use.

Sizes up to 12.00-20, 14-ply and 11-00-22, 12-ply textile and up to 13.00-20 radia!-steel cord. Also Michelin Metallic tyres have similar construction to textile but with steel casing plys and sizes of these go up to the G20 (13-00-20) and E24 (11.00-24). Tread patterns for all types of operation.

Sizes up to 12.00-20, 16-ply textile, up to 10-00-20 14-ply with steel stabilizing plys under tread. Tread patterns for general haulage and on/off-road use.

Sizes up to 14-00-20, 20-ply textile, no radial-steel cord. Tread patterns for general haulage, off-the-road and on/off-road use.

Tyres made by Trefleborgs Gummifabriks AB., of Sweden are marketed. Sizes up to 11.00-20, 16-ply textile, no radial-steer cord. Tread patterns for general haulage off-the-road and on/off-road use.

Tyres made by Metzeler AG., of Germany are marketed. Sizes up to 10-00-20, 14-ply textile, no radial-steel cord. Tread patterns for general haulage and on/off-road use. Larger sizes and off-the-road tyres manufactured by Metzeler in Germany.

Note:

Maximum sizes quoted and alternative carcass types do not necessarily relate to all tread patterns.