Towards the Ultimate in Bus Design

Page 42

Page 43

Page 44

Page 45

If you've noticed an error in this article please click here to report it so we can fix it.

a design latitude which is impossible when the body is mounted on an existing chassis, and the gains are increased if light alloys are used. However, the cost factor, limited production runs and the varying requirements of operators, hamper further progress in these directions; progress would, however, be accelerated if greater weight saving could be achieved and power-unit installation were simplified.

If, for example, a 44-seat bus of 8 ft. by 30 ft. dimensions could be built with an unladen weight of well under 4 tons, and the output of the engine Were sufficient to propel the vehicle economically at high average speeds on service overseas, the operational advantage might encourage almost universal adoption of this type of construction. The suitability of the power unit for many types of passenger and goods vehicle would increase the quantity manufactured and lower production costs.

The estimated weight of under 4 tons is based on the B8 use of a power pack comprising an air-cooled oil engine, transmission, final drive and De Dion-type rear suspension as a complete unit. The transmission and axle casings would be of light alloy, also the wheels, which would save about 2 cwt. and improve the suspension. Single rear wheels would be employed.

Various detailed suggestions regarding the development of a suitable power pack will be made later, but first it is appropriate to give the bodybuilder's opinion on its potential.

According to an authority on body construction, the main advantage of the power pack would be that a standardized range of body shells could be produced to accommodate operators' requirements. These shells' would be designed as integral bodies capable of taking all the bending and torsion loads of the vehicle. The power pack would be mounted on a sub frame comprising two stiff transverse members connected by tubular longitudinaIs. This unit would be attached to

the body shell by cone joints, positioned at the ends of the transverse members and fitting into cast sockets mounted on the body sides.

To change the whole power pack unit would necessitate the removal of only four bolts and disconnecting the controls, the fitting of a reconditioned replacement unit taking a matter of minutes. Using aluminium alloys for the body structure, a stressed inside lining of the side frames (for ease of maintenance) and frontand rear-end panels of fibre glass, the weight of a 44-seat public service vehicle body with a comprehensive specification would be 35 cwt.

Many promising developments contributing to performance have failed to find commercial applications because they do not aid standardization_ To avoid building two or more sizes of engine it has often been suggested as a practical means for achieving standardization that a supercharger be employed on the standard production unit. This would provide an engine of higher power rating whilst retaining all the components of the ordinary unit. .

If the full potential of the supercharger could be realized, the additional increase in the power-to-weight ratio would be a superimposed factor of great tilportance. A supercharger can give a large increase in output with a small increase in maximum cylinder pressures, because the added power is a function of maintaining the pressure over a larger crank angle, but a blower system has yet to be developed commercially which gives the optimum low-speed torque. According to Sir Harry Ricardo, in his 1950 Thomas Hawksley lecture, the torque of an oil engine could be doubled by supercharging without modification of the existing bearings or any other working parts of the power unit.

The maximum b.h.p output could also be raised appreciably, but oil-cooled pistons would be necessary if a similar increase in b.h.p. output were required. All that is wanting is a suitable design of supercharger, or, maybe, a supercharger drive that would provide a variable ratio.

It has been re-stated by transmission experts many times during the past 30 years that if a suitable ratchet could be developed for the Constant inesco infinitely variable gearbox all other forms of transmission would become obsolete overnight. One solution to the problem might be provided by an electric ratchet, with which experiments have already been made, and another by linking the output arm to the plunger of a

hydraulic motor, which would operate at low speed without severe pumping losses. To increase the axle speed a hub step-up gear could be employed.

In the Napier Nomad 3,000 h.p. compound aero engine, an infinitely variable drive of the double-cone type, developed in Germany by Dr. Josef Beier, is used to transmit power between the piston engine and turbo-compressor unit. The principle is simple and ratio variations can be made under full torque. Why cannot it be applied to vehicle transmissions?

It is neither optimistic nor whimsical to conclude that the existing total knowledge on variable drives could be used to develop a unit for transmissions and supercharger drives. Even if the drive were relatively costly to produce, this would be partly or wholly offset by the very wide scope of a single gearbox with regard to speed and torque ratings and the standardization of final drives which it would facilitate. An oil engine with a rating of, say, 70 b.h.p. to 140 b.h.p. in unit with an infinitely variable transmission and standard axle, would have so many applications that a production run could be planned on an unprecedented scale.

With either types of drive mentioned, ratio variation could be made fully automatic in accordance with operational requirements so that fuel consumption would be reduced. If necessary, a hand control would be fitted to vary the torque characteristics.

The air-cooled oil engine has, been successfully developed in Germany, and in this country many operators would welcome such a unit because it would obviate maintenance and cold-weather troubles associated with water-cooling systems. The early onset of ring-sticking and piston-scuffing would be the expected disadvantages, combined with noisy operation.

Reducing Piston Troubles

High-pressure supercharging would reduce or eliminate " Diesel" knock but would tend to aggravate piston troubles, and some means would have to be found to counteract them. This could probably be achieved by using water injection, the possibility of which was also mentioned by Sir Harry Ricardo in the lecture referred to.

A venturi-type air-water mixer would offer the simplest method of metering and control, and if present experiments prove successful the " carburetter " could be employed to introduce volatile fuel to increase the efficiency and output of the unit. The water would be pumped at a suitable pressure into the float chamber, the air space of which would be connected to the main duct between the supercharger and the manifold. A supercharger of the vane type would be the most promising design.

Although water injection has been mentioned as a method of reducing internal temperatures, it would also be beneficial as an inter-cooling device, which would al 0 raise the output by some 15 per cent. 'Oil cooling the cylinder bores is another current development of interest, and might profitably be used for an air-cooled engine. It would accommodate any rapid rise in temperature and obviate temporary seizure when the engine was stopped. It would also reduce mechanical noise.

Engines in buses continually operating at low speeds would be fitted with fully shrouded cooling systems, and those which could be cooled by a natural draught for long periods would have an " open " system with deflector plates.

Controlling Temperature

Dividing the cylinders into horizontally opposed pairs would facilitate cooling, given that a duplicated system Were employed. Electrically driven fans, actuated by thermostats in the oil coolers, would give accurate temperature control, and warming-up would be rapid, as the fans would not operate until the working temperature was reached. This would reduce cylinder-bore wear and fuel consumption. '

Freedom from severe thermal distortion is another virtue of the air-cooled unit, and given that piston troubles could be avoided, it would prolong the period between major overhauls, not only with regard to cylinder-bore wear but also bearing life. With the short crankcase of a four-cylindered opposed unit and the inherent rigidity of the compact crankcase, a period between major overhauls of at least 250,000 miles should be possible. The use of special lubricant additives being developed for air-cooled engines, combined with efficient oil cooling, should enable low-viscosity oils to be successfully employed.

The specification of the engine, based on the foregoing assumptions, might include: bore, 100 mm.; stroke, 150 mm.; capacity, 4.7 litres; output, 70 b.h.p. to 140 b.h.p. at 2,000 r.p.m.; maximum torque, 420 lb.-ft., and maximum b.m.e.p., 220 psi, at 1,200 r.p.m. Oil cooling the pistons might be necessary above a rating of about 120 b.h.p. A comparatively long stroke and slow speed would improve the efficiency and life of the injectors.

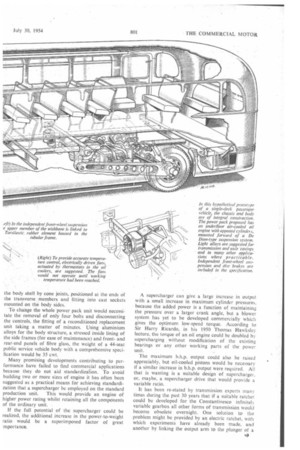

To dispense with the propeller shaft, independent rear suspension of the De Dion type is a necessary feature of any power pack. In the suggested layout the suspension takes the form of torsion bars or rubber elements of the Torsilastic type, which are housed in the tubular members of the sub-frame. It is of interest that this design—with torsion bars—was used for the 1937 Auto Union racing cars.

Another important feature of independent rear suspension is the facility it provides for inboard mounting of the brakes. These would be hydraulically operated disc units, combined with mechanically operated pads for the hand brake; being on the output side of the differential they would not be classed as transmission brakes. The infinitely variable gearbox would give additional braking power, particularly if an exhaust obturator were fitted. The single rear tyres would enable the length of the drive shafts to be increased and their angularity to be reduced. With the exception of the hand-brake linkage, all controls would be hydraulic or electrical, and a junction board for the plugs and couplings would centralize the connections and save pack-removal time.

A version of the power pack could be produced for use at the front of the vehicle, which would involve the complication of driving the steered wheels and would increase front-wheel loading, but the availability of such a unit at little extra cost might be of practical interest to some bodybuilders. With the drive at the rear, independent front-wheel suspension of the wishbone type would be employed, with the upper member linked to a Torsilastic rubber element housed in the tubular frame. The steering would be by a conventional linkage and disc brakes would be employed.

Higher Speed Encouraged In theory, the so-called scrubbing action of the tyres of an independent suspension could cause increased wear at a speed above walking pace, but it is claimed that, in practice, any increase with a . well-designed suspension is the result of the higher tornering speeds which the improved springing encourages. The experience of operators with light commercial vehicles based on a car chassis having a relatively high spring deflection would appear to substantiate the claim.

There are many production advantages associated with the use of a power pack of the type described, which would undoubtedly increase competition between engine manufacturers. The foremost of these is that the factory space required to produce units on a quantity basis would be relatively small. This would reduce overheads and facilitate the production of complete packs by manufacturers who were originally organized for flow production of engines only.

Delivery Costs Reduced

Although the apparent advantage of being able to deliver a self-contained chassis to a bodybuilder would be lost, a number of packs could be loaded on a suitable long-distance vehicle and the cost of providing a driver for each unit would be saved. The saving in space would also be valuable to the bodybuilder.

The need frequently to renew the bodywork of coaches to satisfy public demand for the latest styling is a problem which many operators must take into consideration, and the relatively high cost of a lightalloy body might not, in such a circumstance, be recovered by the saving in running costs. This difficulty, however, would be a challenge to specialist bodybuilders to produce low-cost shells of composite construction, into which the pack could be fitted.

Most operators run service buses in addition to coaches, and power-pack interchangeability, would have obvious applications. In a mixed fleet, and this might later include goods vehicles, one spare power pack should enable the serviceability ratio to be greatly increased.