What swop-body equipment can do for you

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

EVERY manufacturer of demountable body equipment will tell you how the productivity of your company's transport organisation would benefit from the use of his product.

With swop bodies you can get many of the advantages of articulation, in terms of rapid turnround at depots, without the penalties of excessive length and weight on an artic, and without the need for hgv class 1 drivers' licences.

At the same time, swop bodies open up the possibilities of " split trunk " operation with all that implies in avoiding costly double handling. Break-bulk depots can be replaced by a simple body change area, the containers having been stuffed in delivery drop order 200 miles (320km) away or more at a national distribution centre.

These more elaborate applications of demountable equipment are now finding favour with companies looking for real distribution economies. The split-trunk concept has been given a fillip with the advent of Freightliners' " small" container carrying service, launched some two years ago and now, at least, showing signs of user awareness.

Through its associate company SCIDS Ltd, Freightliners is now able to provide the " trunking " leg of a classic three-section swop body distribution scheme, an overnight Freightliner train taking the place of the twoor three-up skeletal artic trunker.

Where an operator has for some years been using demountables on rigid chassis only, to give him a faster rate of vehicle/driver turnround, the chances are that the current industrial recession is having the effect of turning the vehicles into " non-demountables."

The fleet's daily traffic volume is down, say from 20 to 12 container-loads. There is a reluctance to lay off drivers —the drivers themselves probably having engineered some of that reluctance. The obvious,

'Winding clown'

A company is, in any case, more likely to reduce its semiskilled loading bay workforce than its complement of hgvqualified drivers, so that erstwhile demountable drivers, accustomed to spending 90 per cent of their working hours behind the wheel, may find themselves having to assist with loading.

This "winding down" of transport activity has, in consequence, hit many of the demountable equipment makers_ harder than the producers of general-purpose bodywork. But the long-term prospects for swop-bodies look healthy enough. It is reasonable to suppose that fleet managers now going through a quiet period are finding time to plan ahead, to a time when more sophisticated vehicles and correspondingly more elaborate distribution systems will be viable. Alphabetically, the main pro ducers are:

Abel Systems Ltd, 22 Chapel Lane, Pinner, Middlesex.

During the past year, Abel has added two new models to its range which means that the company now caters for the entire range of commercial vehicles in terms of weight and size. First was the lightweight Uni-Swop 327 designed for Ford Transit ,or. Bedford CF-sized chassis. Operated by A single lift pack, the equipment provides for payloads up to 1.75 tons and as with the heavier Abel units body securing is by ISO-type twistlocks.

The low-cost Uni-Swop 737 system allows for 4-ton payloads operating within the " non-hgv" limit of 7.5 tonnes (7.37 tons), with body lengths up to 4.9m (16ft). The design is based on the company's well-proven Abel-Twin ' pneumatic system and sells for around 40 per cent less than its rivals, says Abel.

Arlington Bodybuilders Ltd, High Road, Ponders End, Middlesex. No significant changes have been made to Arlington's electrohydraulic powered clear-lift swop system since I reported its functional test just four years ago, although four rams (front and rear pairs each being linked with a " bolster " crosshead) are used instead of three on the longer heavier versions. Screw threaded hold-down clamps are employed.

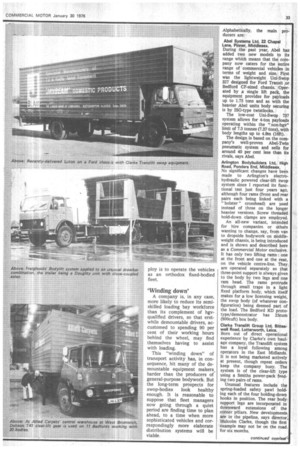

An all-new variant, intended for hire companies, or others wanting to change, say, from van to dropside bodywork on middleweight chassis, is being introduced and is shown and described here as a Commercial Motor exclusive. It has only two lifting rams : one at the front and one at the rear, on the vehicle centre-line. They, are operated separately so that three-point support is always given to the body by two legs and one ram head. The rams protrude through small traps in a light fixed platform body, which itself makes for a low licensing weight, the swop body (of whatever configuration) being deemed part of the load. The Bedford KD prototype/demonstrator has 23cum (800cuft) box body.

Clarke Translift Group Ltd, Bitteswell Road, Lutterworth, Leics. Born out of direct operational experience by Clarke's own haulage company, the Translift system has a loyal following among operators in the East Midlands. It is not being marketed actively at present, though repeat orders keep the company busy. The system is of the clear-lift type using a Smiths power-pack feeding two pairs of rams.

Unusual features include the spring-loaded safety pawl holding each of the four holding-down hooks in position. The rear body: support legs are incorporated in downward extensions of the corner pillars. New developmeott: are in the pipeline, says director; Malcolm Clarke, though the first example may not be on the road, for six months.