From Drivers and Mechanics.

Page 26

Page 27

If you've noticed an error in this article please click here to report it so we can fix it.

TEN SHILLINGS WEEKLY is paid for the best communication received, and one penny a line of ten words for anything else published, with an allowance for photographs.

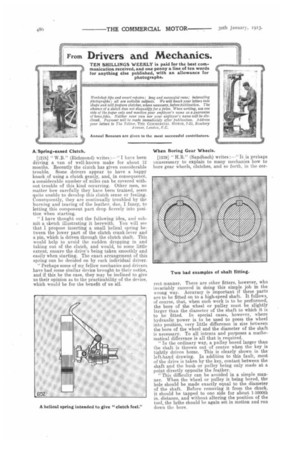

A, Spring-eased Clutch.

[1218] " W.B." (Richmond) writes :—" I have been driving a van of well-known make for about 12 months. Recently the clutch has given considerable trouble. Some drivers appear to have a happy knack of using a clutch gently, and, in consequence, a considerable number of miles can be covered without trouble of this kind occurring. Other men, no matter how carefully they have been trained, seem quite unable to develop this clutch sense or feeling. Consequently, they are continually troubled by the burning and tearing of the leather, due, I fancy, to letting this component part drop fiercely into position when starting.

"I have thought out the following idea, and submit a sketch illustrating it herewith. You will see that I propose inserting a small helical spring between the lower part of the clutch crank-lever and a pin, which is driven through the clutch shaft. This would help to avoid the sudden dropping in and taking out of the clutch, and would, to some little extent., ensure the drive's being taken smoothly and easily when starting. The exact arrangement of this spring can be decided on by each individual driver.

"Perhaps some of my fellow mechanics and drivers have had some similar device brought to their notice, and if this be the case, they may be inclined to give us their opinion as to the practicability of the device, which would be for the benefit of us all. When Boring Gear Wheels.

[1219] " H.R." (Sandbach) writes :—" It is perhaps unnecessary to explain to many mechanics how to bore gear wheels, clutches, and so forth, in the cor

rect manner. There are other fitters, however, who invariably succeed in doing this simple job in the wrong way. Accuracy is important if these parts are to be fitted on to a high-speed shaft. It follows, of course, that, when such work is to be performed, the bore of the wheel or pulley must be slightly larger than the diameter of the shaft to which it is to be fitted. In special cases, however, where hydraulic power is to be used to press the wheel into position, very little difference in size between the bore of the wheel and the diameter of the shaft is necessary. To all intents and purposes a mathematical difference is all that is required.

"In the ordinary way, a pulley bored larger than the shaft is thrown out of centre when the key is tightly driven home. This is clearly shown in the left-hand drawing. In addition to this fault, most of the drive is taken by the key, contact between the shaft and the bush or pulley being only made at a point directly opposite the feather. "This difficulty can be avoided in a simple manner. When the wheel or pulley is being bored, the hole should be made exactly equal to the diameter of the shaft. Before removing it from the chuck, it should he tapped to one side for about 1-1000th in. distance, and without altering the position of the tool, the lathe should be again set in motion and run down the bore. " By this means the pulley has a slight cut taken off one side. The keyway should then be cut in the higher part of the shaft, and when driven in tightly it pulls the work absolutely concentric. In addition, the job is a better fit on the shaft, This is an important feature when boring gear wheels, as, if the outside diameter is out of truth with the shaft, it is impossible to obtain a silent or a sweet-running transmission."

An Arrangement for Boring Split Bushes, 1220j " R.T." (Bedford Hill) writes :—" I enclose sketch We have had this redrawn.—ED.] which illus trates an arrangement for boring split bushes, espe cially after they have been re-metalled. When this holder is used, the usual chucking method employed is unnecessary.

"1 have often noticed that, when holding split bushes in an ordinary jaw-chuck, the flanges alone are relied on for holding the hush in position, and, unless undue pressure is exerted by the chuck jaws, the tendency is for the work to shift slightly under a heavy cut.

"The method which I employ consists of a castiron block bored out to the outer diameter of the bush barrel. This block is split in halves. The two pieces are then secured to an angle-plate mounted on the face-plate of the lathe, and the job is balanced with any suitable balance weight. A much heavier cut can be taken when this method of chucking is used, and a quicker and coarser feed can be taken for roughing. A smoother cut may be employed as a finisher which will be found to be free from chatter, provided, of course, that the headstock borings and the bed of the lathe are in good condition.

" Any reasonable variation in the diameters of bushes may be allowed for by packing inserted round the barrel before tightening up the holding-down bolts of the jig. When dealing with a fair number of bushes, all of which are of the same size, much time can be saved, as there is no necessity for each part to be trued up separately. In addition, the slide rest may be marked off, so that the use of callipers can be, to a large extent, avoided, and the bore will be the same in all the bushes."

Boring to a Pine Limit.

The sender n f the following communication has been awarded the log. prize this week.

[1221] " T.P." (Dalston) writes :—" T read with the greatest interest letter No. 1215 by 'X ' (Cardiff), which was headed 'A Cocoa-tin test for Accuracy.' I must thank your correspondent for the useful little dodge which he brought to my notice, viz., that of using a tin as a vibrator or receiver. 1 think that he might well have stated that the use of a small emery wheel in the manner described is more generally eniployed when re-boring or grinding cylinders. There are many drivers who have the use of a lathe in the repair shop, who are qUite fit and competent to tackle the everyday repair, but who always send cylinders which require re-boring to some outside firm. There is no need for this to be done. It is not necessary to rig up an expensive plant in order to make a. satisfactory job of this repair. A bush fitted with ball bearings, and having a shaft which may be of any reasonable required length, can be purchased for about £3. The shaft is fitted on one end with a II-grooved pulley, and on its other end a, small emery wheel can be fixed. The appliance can be driven either by means of an overhead gear or by a treadle motion.

" When it is necessary to, grind out the cylinders, this bush is held by. the tool clamps. The cylinders are gripped in the usual way, either in an independent jaw chuck, if the shape of the casting allows of this being done, or on an angle plate attached to the face plate A suitable lathe speed is selected, and the feed to the emery wheel can be given either from the traverse arrangement at the back of the lathe or by means of the leading screw. If the latter be employed, a feed of about 90 or 100 to the inch should he used. All that is necessary then is to drop the nut into the screw, and by means of the treadle or the overhead motion to give the emery wheel a speed of 1500 to 1800 r.p.m. This will ensure a beautifullypolished surface being given to the cylinder bore, and if the hints given by your correspondent of last week be followed, a parallel hole will result."

A Hand-operated Valve-seat Cutter.

[1222] " R.T." (Bedford Hill) writes :—" You will see from the rough sketch which I enclose [We have had this redrawn.—En.] that a valve-seat cutter, to be worked by hand, is not an expensive or a complicated appliance. One advantage of such a tool is that a. pressure almost equal to that of a machinedriven tool can be obtained.

"If a machine valve-seater is employed, it is necessary that the cylinders should be removed before the seats can be skimmed up. With the use of the screwed cap, however, which is plainly to be seen in the sketch, the cut can be regulated, and the spindle turned with a spanner."