Exhaust Braking for Two-stroke Engines

Page 52

If you've noticed an error in this article please click here to report it so we can fix it.

T0 enable the compression of a twostroke engine to be used for

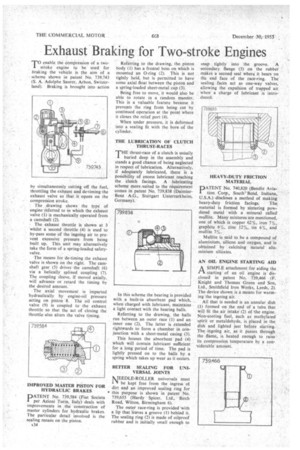

• braking the vehicle is the aim of a • scheme shown in patent No. 739,743 (S. A. Adolphe Saurer, Arbon, Switzerland). Braking is brought into action by simultaneously cutting off the fuel, throttling the exhaust and de-timing the exhaust valve so that it opens on the compression stroke.

The drawing shows the type of engine referred to in which the exhaust valve (1) is mechanically operated from a camshaft (2).

The exhaust throttle is shown at 3 whilst a second throttle (4) is used to by-pass some of the ingoing air to prevent excessive pressure from being built up. This unit may alternatively take the form of a spring-loaded safetyvalve.

The means for de-timing the exhaust valve is shown on the right. The camshaft gear (5) drives the camshaft (6) via' a helically splined coupling (7). The coupling sleeve, if moved axially, will advance or retard the timing by the desired amount.

The axial movement is imparted hydraulically by engine-oil pressure acting on piston 8. The oil control valve (9) is coupled to the exhaust throttle so that the act of closing the throttlo also alters the valve timing.

IMPROVED MASTER PISTON FOR HYDRAULIC BRAKES

PATENT No. 739,584 (Fiat Societa per Azioni Turin, Italy) deals with improvements in the construction of master cylinders for hydraulic brakes. The particular detail involved is the sealing means on the piston. Referring to the drawing, the piston body (1) has a frontal boss on which is mounted an 0-ring (2). This is not tightly held, but is permitted to have some axial float between the piston and a spring-loaded sheet-metal cup (3).

Being free to move, it would also be able to rotate in a random manner. This is a valuable feature because it prevents the ring from being cut by continued operation at the point where it closes the relief port (4).

When under pressure, it is deformed into a sealing fit with the bore of the cylinder.

THE LUBRICATION OF CLUTCH THRUST-RACES

THE thrust-race of a clutch is usually buried deep in the assembly and stands a good chance of being neglected in respect of lubrication. Alternatively, if adequately lubricated, there is a possibility of excess lubricant reaching the clutch facings. A lubricating scheme more suited to the requirement comes in patent No, 739,838 (DaimlerBenz A.G., Stuttgart Unterturkheim, Germany).

In this scheme the bearing is provided with a built-in absorbent pad which, when charged with lubricant, maintains a light contact with the bearing balls.

Referring to the drawing, the balls run between an outer race (1) and an inner one (2). The latter is extended rightwards to form a chamber in conjunction with a sheet-metal casing (3).

This houses the absorbent pad (4) which will contain lubricant sufficient for a long period of time. The pad is lightly pressed on to the balls by a spring which takes up wear as it occurs.

BETTER SEALING FOR UNIVERSAL JOINTS MEEDLE-ROLLER universals must 11 be kept free from the ingress of dirt and an improved sealing ring for

• this purpose is shown in patent No. 739,655 (Hardy Spicer, Ltd., Birch Road, Witton, Birmingham 6).

The outer race-ring is provided with a lip that leaves a groove (1) behind it. The sealing ring (2) is made of oilproof rubber and is initially small enough to snap tightly into 'the groove. A secondary flange (3) on •the rubber makes a second seal where" it bears on the end face of the race-ring. The sealing faces act as one-way valves, allowing the expulsion of trapped air when a charge of lubricant is introduced.

HEAVY-DUTY FRICTION MATERIAL

DATENT No. 740,820 (Bendix Avia

tion Corp., South 'Bend, Indiana, U.S.A.) discloses a method of making

heavy-duty friction facings. The material is formed by sintering powdered metal with a mineral called mullitc. Many mixtures are mentioned, one of which is copper 62%, iron 7%, graphite 6%, zinc 12%, tin 6%, and mullite 7%.

Mullite is said to be a compound of aluminium, silicon and oxygen, and is obtained by calcining natural aluminium silicates.

AN OIL ENGINE STARTING AID

ASIMPLE attachment for aiding the starting of an oil engine is disclosed in patent No. 739,466 (F. Knight and Thomas Green and Son, Ltd., Smithfield Iron Works, Leeds, 2). The device shown is a means for warming the ingoing air.

All that is needed is an annular dish (1) formed on the end of a tube that will fit the air intake (2) of the engine. Non-sooting fuel, such as methylated spirit or metaldehyde, is placed in the dish and lighted just before starting. The ingoing air, as it passes through the flame, is heated enough to raise its compression temperature by a con • siderable amount.