WILL THE WOODE BODY SURVIVE.?

Page 38

Page 39

Page 40

Page 41

If you've noticed an error in this article please click here to report it so we can fix it.

THE rapid development of road transport has produced many radical modifications in the construction of commercial bodywork, and accumulated experience and advancement of ideas are constantly demanding improvements in all directions. Unlike the chassis, which was introduced for the specific purpose for which it is used to-day, bodywork dates from the earliest days, and many severe jolts have been.required to shake it out of the old ruts in order to bring it to its present state of efficiency, for coachbuilding in pre-motor days was one of the most conservative of trades.

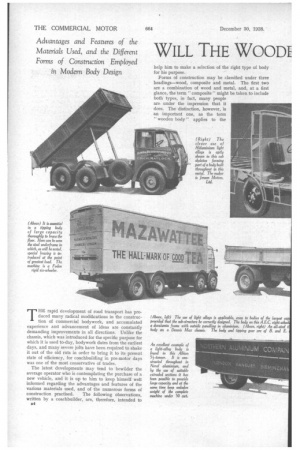

The latest developments may tend to bewilder the average operator who is contemplating the purchase of a new vehicle, and it is up to him to keep himself well informed regarding the advantages and features of the various materials used, and of the numerous forms of construction practised. The following observations, written by a coachbuilder, are, therefore, intended to 04 help him to make a selection of the right type of body for his purpose.

Forms of construction may be classified under three headings—wood, composite and metal. The first two are a combination of wood and metal, and, at a first glance, the term " composite " might be taken to include both types, in fact, many people are under the impression that it does. The distinction, however, is an important one, as the term " wooden body applies to the

oldest, and up to the present, most general type. Such a body consists of a wood foundation on framework, reinforced with metal—generally iron or steel—which may be covered with metal panels.

Composite bodies have metal foundation or framework, with wooden members introduced for convenience or other reasons, and in areas where it is considered more suitable.

Bodies which may be described as strictly all-metal are comparatively rare, excluding, of course, those built for special

purposes, such as refuse collection, or as containers for liquids. The term " metal body," ,however, is usually applied to one having a minimum amount of wood or other non-metallic substance in its construction.

We will, first of all, consider the various properties, faults and advantages appertaining to each form of construction, and note how these affect, and are affected by, the conditions which are set up by the widely varying requirements of road transport. Wooden bodies have had, by far, the longest test. Consequently, we have a more complete knowledge of the capabilities and deficiencies of this form of construction than of any other, and it is largely owing to this fact that the search after an alternative has been so widely instituted.

Owing to its low ratio of density it is the best insulating medium of any of the materials used in the construction of bodywork. Whilst it offers less resistance to applied force and will break up more easily than steel, it is easier and 'less expensive to repair. especially where the

steel body is constructed with riveted or welded joints. This does not apply in the case of a metal body built up in units, as is sometimes the case with buses, as in such cases complete units are kept in stock for replacement. For single bodies, it is considerably cheaper to build a wooden body than any other type.

In cases where the load to be carried is of a rough, hard nature such as bricks, stone, or heavy iron goods, a considerable amount of friction may be set up between the load and the floor, and it is often found necessary to protect the floor and the superstructure with. iron plates, which should be secured with bolts along the edges.

Wood absorbs vibration to a high degree, and it will damp out road shocks to a greater estent than any other basic material normally used in commercial body construction.

There are, however, two outstanding disadvantages connected with its use. First, it is subject to comparatively rapid deterioration if continuously exposed to the elements without ade quate protection; secondly, the great loss of strength which is inseparable from every type of wood joint that has ever • been devised, despite the elaborate amount of plating that is often brought into service to counteract this failing. It cannot be claimed that, without

considerable reinforcement, the best of joints retains more than 50 per cent. of the initial strength of the section.

Therefore, it frequently happens that stresses may be localized at points where resistance has of necessity been weakened, as for instance where a load is transmitted through a pillar which is morticed or half-lapped to a rail. A lesser, but, nevertheless,, insistent and provoking fault to be found in wood is its tendency to absorb moisture, with consequent expansion and contraction according to the variation of humidity and temperature of the atmosphere. This, however, operates in only one direction—across the grain—the length remaining constant.

Owing to the bending movement, and the weakness of joints as already referred to, wood is not well fitted to withstand localized stresses, and the comparatively low degree of adhesion of the fibres renders it liable to split at bolt holes, tenon shoulders, and other places, whilst screws become loose when stresses exceed the normal.

Most timbers take paint well, that is those of the oil or synthetic variety; cellulose must never be applied to wood. Oak and teak, on account of their oily nature, do not take paint quite so well as the average, and some of the soft woods, such as cottonwood, will often shed the paint in patches after it has become dry and hard.

For shock insulation and .toughness ash is the best of all timbers and, consequently, the most favoured for framework. It has, however, rather lower powers of resistance to rot, and unless it be kept well painted, will quickly deteriorate. It is reasonably light for a hardwood, weighing about 46 lb. per cubic ft., as against, approximately, 58 lb. for oak. For stiffness, strength, and resistance to rot, oak is unequalled. One disadvantage is that it rapidly oxidizes steel and iron, and whenever these metal:, come into contact with it the oak should previously be well painted and allowed to dry.

Where floorboards come in for excessive wear and lining with steel is inadvisable, oak boards are recoramended as the hardest wearing boards for the purpose, but frequently weight and cost are prohibitive. In such cases, larch makes a good substitute, being both cheaper and lighter, whilst it also possesses the advantage of being probably the least subject, of any tindrio>r, to contraction and expansion. Oak is among the worst offenders in this respect. Repairs to wooden bodies are comparatively easy to execute.

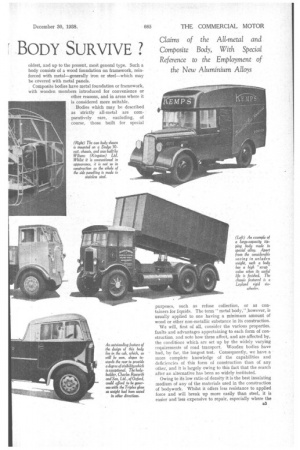

The composite body is, at the moment, in an early stage of development, but its possibilities are such that it may well become the most popular form of construction, as it is capable of embodying and co-ordinating the best features of the others. A good example of composite construction is to be fOund in many drivers cabs in use to day. Those which the writer has in mind at the moment have panels, which are generally stamped out in one piece, such panels, in many cases, imparting the main strength to the struc ture. It is usual to line them with a skeleton framework to stiffen the edges, and to provide a framework for the bottom boards.

Drumming is counteracted by felt padding or other prepared substances. The foundation framework is usually of wood, as are also the floor and rear framing. As the tools for shaping the panels are an expensive item, the cost has to be spread over a large number of bodies, which means quantity or mass production.

One result, which accrues, is the smart curved lines almost equalling those of the private car; the cost would be prohibitive if such lines had to be produced in the old coachbuilding manner, with all the curves shaped in wood framing, and covered with beaten panels.

Another example of the composite form of construction is to be found in the tipping-lorry body, where the subframe is of steel construction, and the upper structure of wood which is steel lined.

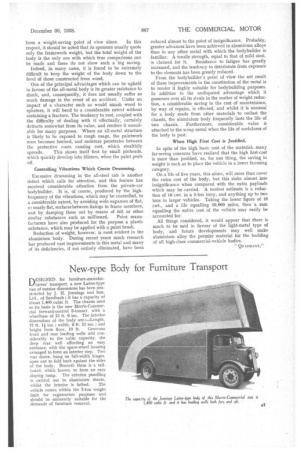

Probably the most notable advance in body construction has been in what is termed the all-metal body. Steel was the metal first to claim attention for this purpose, and, to-day, we have various forms of tubular and channel sections, of astonishing lightness coupled with great strength, specially fabricated for use in the framework of van bodies.

At the same time, owing to the fact that steel is about 12 times the weight of ash, little can be said in its favour from a weight-saving point of view alone. In this respect, it should be noted that its sponsors usually quote only the framework weight, but the total weight of the body is the only one with which true comparisons can be made and these do not show such a big saving.

Indeed, in many cases, it is found to be extremely difficult to keep the weight of the body down to the level df those constructed from wood.

One of the principal advantages which can be upheld in favour of the all-metal body is its greater resistance to shock, and, consequently, it does not usually suffer so much damage in the event of an accident. Under an impact of a character such as would smash wood to splinters, it will bend to a considerable extent without sustaining a fracture. The tendency to rust, coupled with the difficulty of dealing with it effectually, certainly detracts somewhat from its value, and renders it unsuitable for many purposes. Where an all-metal structure is likely to be exposed to rough usage, the paintwork soon becomes bruised, and moisture penetrates between the protective coats causing rust, which stealthily spreads. This shows itself first by small pinheads, which quickly develop into blisters, when the paint peels off.

Controlling Vibrations Which Create Drumming.

• Excessive drumming in the all-steel cab is another defect which calls for attention, and this feature has received considerable attention from the private-car bodybuilder. It is, of course, produced by the highfrequency of the vibrations, which may be controlled, to a considerable extent, by avoiding wide expanses of flat, or nearly flat, surfaces between fixings to frame members, and by damping these out by means of felt or other

similar substances such as millboard. Paint manufacturers have also produced for the purpose a plastic substance, which may be applied with a paint brush.

Reduction of weight, however, is most evident in the aluminium body. During recent years much research has produced vast improvements in this metal and many of its deficiencies, if not entirely eliminated, have been reduced almost to the point of insignificance. Probably, greater advances have been achieved in aluminium alloys than in any other metal with which the bodybuilder is familiar. A tensile strength, equal to that of mild steel, is claimed for it. Resistance to fatigue has greatly increased, and the tendency to deteriorate from exposure to the elements has been greatly reduced.

From the bodybuilder's point of view the net result of these improvements in the constitution of the metal is to render it highly suitable for bodybuilding purposes. In addition to the undisputed advantage which it possesses over all its rivals in the matter of weight reduction, a considerable saving in the cost of maintenance, by way of repairs, is effected, and whilst it is unusual for a body made from other materials to outlast the chassis, the aluminium body frequently lasts the life of two chassis. Furthermore, considerable value is attached to the scrap metal when the life of usefulness of the body is past.

When High First Cost is Justified.

In spite of the high basic cost of the material-,..many far-seeing concerns have realized that the high first-cost 'is more than justified, as, for one thing, the saving in weight is such as to place the vehicle in a lower licensing category.

On a life of five years, this alone, will more than cover the extra cost of the body, but this sinks almost into insignificance when compared with the extra payloads which may be carried. A modest estimate is a reduction of 10 cwt. in a 5-ton lorry, and anything up to two tons in larger vehicles. Taking the lower figure of 10 cwt., and a life equalling 50,000 miles, then a sum equalling the entire cost of the vehicle may easily be accounted for:

All things considered, it would appear that there is much to be said in favour of the light-metal type of body, and future developments may well make aluminium alloy the premier material for the building of all high-class commercial-vehicle bodies.

QUADRANT."