Landtrain just keeps on rolling along

Page 23

Page 24

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

1HE EFFECTS of the unpre:edented attack on the British ;ommercial vehicle market ;ince the late Sixties are still )eing acutely felt.

The once-secure province of he home producer has been ncreasingly eroded with the irrival of each foreign manufacurer to the extent that any new ;ompany on the scene would low have to compete for sales jained by foreign companies as veil as those retained by British :oncerns.

Inducements to buy foreign n terms of discounts and so in would have been considered :ommercial suicide if made wadable in the home importers' ;ountries. But, understandably, 3ritish operators were not slow o take advantage of the situaion — snapping up the best feels as they were offered.

As with all good things, these 'perkscan't go on for ever. Eventually the Continental nasters will require a proper eturn for their investments and hat time must be close at hand perhaps, for some, already iere.

Leyland, the champion of the 3ritish commercial vehicle in lustry, but with an ageing range if models, was easy prey for the nore sophisticated imports.

iasty attempts to compete were iot backed by adequate spares ir service, while its passenger :ar interest degraded the corpo rate image still further.

Once again, Leyland Vehicles sole interest is with commercialvehicle production. A planned investment of £60m a year over the next five years is destined to provide it with one of the most modern production facilities in the business.

If the British commercial. vehicle is to have any chance of survival it must compete with

allcomers. Although there has been a reluctance by some to buy the home-produced product, this should not deter manufacturers to compete abroad as there are still many areas of the world where Made in Britain seems to carry more weight than it does here.

The world market is immense, and even a small slice of it can mean big business.

LV's worldwide export operations are considerable, grossing in the region of £600m per year. In addition to its 15 manufacturing plants in Britain, it owns interests in 20 in Europe and more in the developing world.

Just before the introduction of the long-awaited T45, the company announced its Landtrain range for export.

Eight bonneted models rated for operation between 19 tonnes to 65 tonnes make up the range which has been specifically designed for operation in the Middle East, the Far East, Africa and Latin America.

An investment of £5.5m in new painting and welding facilities has been made to re-equip the old Guy factory in Wolverhampton where LV plans to produce 1000 units this first year, increasing to double that amount by the end of the second year's trading.

Export will take two forms — either as fully built-up units or as completed sub-assemblies which will allow a degree of local involvement in the country of destination.

Nigeria is just one of the nations encouraging the concept of a local build. This summer LV's new CV plant in lbadan will begin assembly of twoand three-axle models for rigid, drawbar and articulated applications. The new models will supersede such old and wellestablished names as the Super Hippo and Super Beaver, with supplementary models like the Marathon, Scammell LD55 and Scammell Crusader.

I asked LV for a test drive, but the English countryside hardly resembles the Nigerian bush. Or does it? LV said they knew of somewhere suitable to test it.

As a model for export the range had to be designed and developed to withstand wide variations in climatic and environmental conditions. Scammell's military involvement provided a ready source of knowledge and experience in what was needed to make a vehicle reliable for such conditions, so little wonder that the final specification conforms closely to that provided for military application.

For our test, LV provided a 19-21 model loaded to the full plated weight of 36 tonnes. The chromium model plate attached to the cab door denotes first the total solo weight, in this instance 19 tonnes, and second the power rating for the engine (210bhp).

But the vehicle plate belies the true strength of both chassis and suspension which allows for continued overleaf

an expected overload of around 20 per cent. Working conditions are such that loading tends to be limited by the size of the body with almost total disregard of any constraints which might be indicated by use of a weighbridge.

Fitted with Leyland's own L12 naturally aspirated straight-six diesel engine developed from the Marathon TL12 turbocharged unit, the 19-21 is the least powerful of the range. Other power options include a low-revving version of the TL12 which, while giving the same power output of 21 OkVV (282bhp), it develops 1205Nrn (889 lbft), ten per cent more torque.

The big camshaft profile of Cummins NHC250 gives a high injection rate and economical fuel consumption figures. A turbocharged version of the same engine, the NTE290, is yet another option.

The simple but strong bolted ladder-type chassis frame is a development of a design used for the Scammell Contractor. Flitch plates added to each of the main side members minimise stress by distributing the effects of high point loading over a greater area.

Conventional semi-elliptic multileaf springs, eye-mounted at the front and shackled at the rear, locate the front axle and are assisted by double-acting telescopic dampers. The rear axle is similarly mounted, but with 6x4 models a fully articu lated two-spring bogie suspension balances on a control trunnion with oil-bath lubrication.

All Landtrain models are fitted with Leyland axles rated at 6.6 tonnes at the front. A Marathon-type hub-reduction axle rated at 13 tonnes is standardised on the 4x2 units, while the tandem drive, for the 6x4 units, had to be redesigned.

Three types of gearbox are specified — one to match the torque output of each of the various engine options. A sixspeed ZFAK6-90 unit is used with the Cummins 250, a ninespeed Fuller RT09509A or B range-change constant mesh box with the more powerful NTE290 and the TL12 engines, while on our test vehicle a constant-mesh six-speed Eaton 0403 gearbox with overdrive was specified.

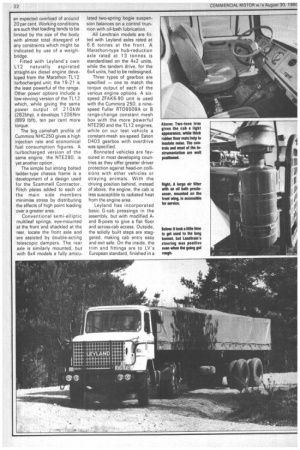

Bonneted vehicles are favoured in most developing countries as they offer greater driver protection against head-on collisions with other vehicles or straying animals. With the driving position behind, instead of above, the engine, the cab is less susceptible to radiated heat from the engine area.

Leyland has incorporated basic 3-cab pressings in the assembly, but with modified A and B-posts to give a flat floor and across-cab access. Outside, the solidly built steps are stag gered, making cab entry easy and exit safe. On the inside, the trim and fittings are to LV's European standard, finished in a light but serviceable two-tone colour scheme.

A Cox driver's suspension seat is fitted as standard, but would be improved if the plastic was replaced with material side panels. For the Nigerian market, left-hand-drive controls are specified but rhd is available for other markets.

First, we took the vehicle onto a normal tarmac-surfaced track. The ride was very smooth and vision ahead was good but close vision was impaired by the bonnet. Corner windows behind the seats aid vision to the rear, from a cab which is less than the 'full lorry width but large enough to seat three persons.

Ventilation is provided in the foot wells, at facia level, and by a six-way roof hatch. Hubbard air-conditioning is available as an option.

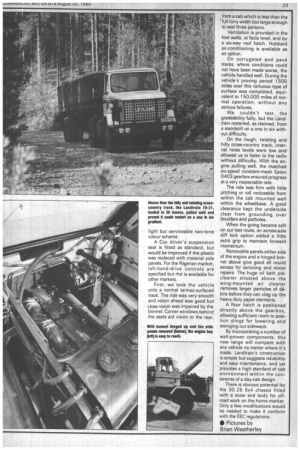

On corrugated and pave tracks, where conditions could not have been made worse, the vehicle handled well. During the vehicle's proving period 1 500 miles over this tortuous type of surface was completed, equivalent to 150,000 miles of normal operation, without any serious failures.

We couldn't test the gradeability fully, but the Land train restarted, as claimed, from a standstill on a one in six without difficulty.

On the rough, twisting and hilly cross-country track, inter nal noise levels were low and allowed us to listen to the radio without difficulty. With the en gine pulling well, the matched six-speed constant-mesh Eaton D403 gearbox ensured progress at a very respectable rate.

The ride was firm with little pitching or roll noticeable from within the cab mounted well within the wheelbase. A good clearance kept the underside clear from grounding over boulders and potholes.

When the going became soft on our test route, an across-axle diff lock option added a little extra grip to maintain forward momentum.

Removable panels either side of the engine and a hinged bon net above give good all round access for servicing and minor repairs. The huge oil bath pre cleaner situated above the wing-mounted air cleaner removes larger particles of debris before they can clog up the heavy duty paper elements.

A floor hatch is positioned directly above the gearbox, allowing sufficient room to position slings for lowering and swinging out sideways.

By incorporating a number of well-proven components, this new range will compete with any vehicle no matter where it's made. Landtrain's construction is simple but suggests reliability and easy maintenance, and yet provides a high standard of cab environment within the constraints of a day-cab design. There is obvious potential for the 30.29 6x4 chassis fitted with a scow end body for offroad work on the home market. Only a few modifications would be needed to make it conform with the EEC regulations.

• Pictures by Brian Weatherley