CONVERSION TO COAL-GAS.

Page 16

Page 17

If you've noticed an error in this article please click here to report it so we can fix it.

Hints and Wrinkles to Garage Proprietors on Fitting-out.

HE GAS IN passing from the container to the motor should have an amPle unimpeded -flow;

• The wind, even that created by the car itself, tends. to drive the gas to the resr;of the bag and' to throttle the outlet by flapping the flabby fabric over

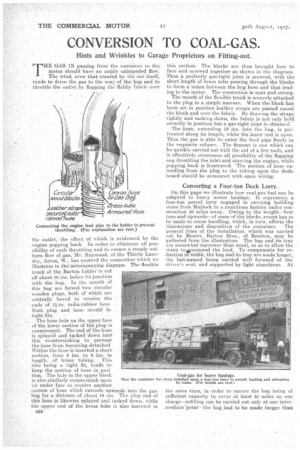

the -outlet, the effect of which is evidenced by the engine popping back, In order., to eliminate all pos

sibility of such throttling and to ensure a steady uniform floW.of gas ,• Mr. Raymond, of the Thistle Laundry,' Acton, W., has evolved the connection which we illustrate in the-aeCiMapanYing diagram. The flexible trunk of the Barton bolder is. cuf off about 10 ins, below it junction Avith the bag. • in the mouth of this bag are forced two circular wooden plugs, both of which are centrally bored to receive' the

ends of india-rubber hose Bothplug and hose should be tight fits. •

The hose hole on the upper face of the lower section of the plug is counterSunk. The end of the hose is splayed and tacked down intd this countersinking to prevent the hose front becoming detached Within the hose is inserted a short section, from 6 ins. to 8 ins.in length, of brass tubing. This also being a tight fit, tends to . keep the section of hose in posi tion. The bele in the upper block is also similarly countersunk upon itS under face to receive another section of hose which extends upwards into the gasbag for a distance of .abciut 1.8 ins_ The plug end of this hose iS likewise splayed and tacked down, while the upper end of the brass tube is also inserted in

Hov

this section. • The blocks are then brought face to face-and. screwed together as shown in the diagram. -Thus a. perfectly gin-tight joint is secured, with the short length Of brass tube passing through the blocks to form a union between the bag hose and that leading to the Motor. The connection is neat and strong.

The mouth of the flexible trunk is securely.attached to the plug, in a simple manner. When the block-has been set in position leather straps are passed round the block, and over the fabric, By drawing the straps tightly and tacking down, the fabric is not only held -securely in position but a gas-tight joint is,..obtained.. The -hose, extending 18 ins', into the bag, is perforated along its length, while the-inner end is open. Thus the gas is able to enter the feed pipe freely in the requisite volume.. The fitment is one which can be quickly carried out with the aid of a• few tools, and it effeCtively. overcomes all possibility of the flapping bag throttling the inlet and starving the engine, while popping..back is frustrated. The section of hose extending from the plug, to the tubing upon the dashboard shtiuld be armoured with open wiring.

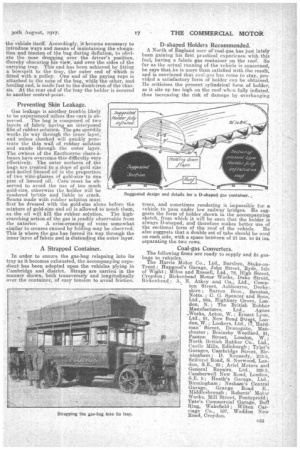

Converting a Four-ton Deck Lorry..

04 this page we illustrate how coal-gas fuel. can be adapted to heavy motor 'haulage. It represents A. four-ton petrol lorry engaged in carrying building stone frorn.Matloek to. a munitions factory under construction 40 miles away. Owing to the weight—four tons and upwards—of some of the blocks, resort has to be, made to crane handling, which, in turn, affects the "dimensionsand disposition of the container. The general lines of the installation, which was carried out by Messrs. Barton Bros, of Beeston, may be gathered from the illustration. The.bag and its tray are somewhat narrower than usual, so as to allow the crane tocoominand the load. To cortipensate for reduction in width, the bag and its tray are made longer, the last-named being carried well forward of the driver's seat, and supported by light stanchions. At the same time, in order to ensure the bag being of sufficient capacity to cover, at least 20 miles on one charge—refilling can be carried out only at one intermediate 'point—the bag had to 'be made longer than,

the vehicle itself. Accordingly, it became necessary to introduce ways and means of maintaining the elongation and tension of the bag during deflation, to obviate the nose dropping over the driver's position, thereby obscuring his view, and over the sides of the carrying tray. This end has been achieved by fitting a bowsprit to the tray, the outer end of which is fitted with a pulley. One end of the paying rope is attached to the nose of the bag, while the other, and hauling end, is made fast to the dumb-iron of the chasgig. At the rear end ef the tray the holder is Secured to another central-point.

Preventing Skin Leakage.

Gas lea-kage is another trouble likely to be experienced unless due care is observed. The bag is composed of two layers of fabric having an interposed film of rubber solution. 'The gas speedily works its way through the inner layer; and unless checked will quickly penetrate the thin wall of rubber solution and exude through the outer layer. The owners of the Eastbourne chars-abanes have overcome -this difficulty very effectively. The outer surfaces of the bags are treated to a dope of gold size and boiled linseed oil in the peoportion of two wine-glasses of gold-size to one pint of linseed oil. Care 'must be observed to avoid the use of too much gold-size, otherwise the holder will be rendered brittle and liable to crack. Seams made with rubber solution Must first be dressed with the gold-size alone before the mixture of gold-size and oil is allowed to touch them, as the oil will kill the rubber solution. The high-searching action of the gas is readily observable from

the exterior. A cries-crossing of veins somewhat similar to creases caused by folding may be observed. This is where the gas has forced its way through the inner layer of fabric and is distending the outer layer.

Suggeslid IfoiderAlty .e.;?fiated A Strapped Container.

In order to ensure the gas-bag relapsing into its tray as it becomes exhausted, the accompanying expedient has been Adopted upon the vehicles plying in Cambridge and district. Straps are carried in the manner shown, both transversely and longitudinally over the container, of easy tension to avoid friction.

• D-shaped 'Holders Recommended.

A North of England user of-coal-gas has just lately been gaining his first practical experience with this fuel, having a fabric gas container on the roof. So far as the actual running of the vehicle is concerned, he says that lie is more than satisfied with the result, and is convinced that coal-gas has come to stay, provided a satisfactory form of holder can be obtained. He criticises the present cylindrical form of holder, as it sits up too high on the roof when fully inflated, thus increasing the risk of damage by overhanging trees, and sometimes rendering it impossible for a• vehicle to pass under low railway bridges. He suggests the form of holder showa in the accompanying sketch, from which it will be seen that the holder is always D-shaped, and therefore makes better use of the sectional form of the roof of the vehicle. He also suggests that a double set of tabs should be used on each side, with a space between of 21 ins. to 24 ins. separating the two rows.

Coal-gas Converters.

The following firms are ready to supply and fit gasbags to vehicles.

The Harris Motor Co., Ltd., BursIem, Stoke-onTrent ; Hapgood.'s Garage, John Street, Ryde, Isle of Wight ; Milne and Russell, Ltd., 72; High Street, Croydon ; Birkenhead Motor Works, Duke Street, Birkenhead ; A R. Atkey and Co., Ltd., Compton Street, Ashbourne, Derbyshire ; Barton Bros., Beeston, Notts. ; C. G. Spencer and Sons, Ltd., 56a, Highbury Grove, London, N.; • The British Rubber Manufactures, Ltd. Agnes .Works, Acton, W. ; Ernest Lyon, Ltd., 91, New Bond Street, London, W.; Lookers, Ltd., 17, 'Hardman Street, . Deansgate, Manchester; Brameby Woollard, 21, Panton Street, London, W.; North British Rubber Co., Ltd., Castle Mills, Edinburgh ; Tyler's. Garages, Cambridge Street, Bireinghare ; D. Kennedy, 213-5, Selhurst Road, S. Norwood, London, S.E., 25; Ariel Motors and General Repairs, Ltd., 320-2,_ Camberwell New Read, London, S.E. 5; Heath's Garage, Ltd., Birmingham; Neshaen's Central Garage, Grange Road E., Middlesbrough; Roberts' Mote! Works, Mill Street, Pontypridd.; Tate's Commercial Garage, Bill/ Ring, Wakefield ; Wilton Carriage Co., 107,, Waddon New Road, Croydon.