AN IMPORTANT INVENTION.

Page 12

Page 13

If you've noticed an error in this article please click here to report it so we can fix it.

A New Carburetting Device Employing Temperatures in Relation to Velocities.

T0 STATE THAT there has been a considerable amount of research work in connection with' the carburation of oil fuel for highspeed internal-combustion engines would be to state the obvious, but hitherto nothing has been made known in this country, except to those who have been brought directly into contact with it of the research work extending over the past ten years of Mr. A. Donald Paterson, and his father (nowdeceased), of Christchurch, New Zealand. Mr. Paterson has aimed at securing a definite relation, in carburation for internal-combustion engines, between temperature and velocity. We have closely followed his efforts towards this end and incline to the opinion that an epoch in the development of the carburetter has now been marked and that an entirely new line of thought. in connection therewith will virtually have been definitely initiated. We put it in that way because other experimenters and theorists in this country, searching for a pathway through the tangle, have, to our certain knowledge, actually glimpsed the light at the far end and then lost it again, but, now that the light shines strongly, they will recognize the pathway to be followed.

The recognized difficulties in carburation have been many. The basic difficulty is that no liquid hydrocarbon fuel is homogeneous, and this trouble has grown worse in recent years, and must continue to grow worse with the growing demand for liquid fuel. Lack of homogeneity of the fuel results inevitably in (1) the explosion of the lighter elements vaporized by the velocity, (2) the partial burning of the heavier elements, and (3) the wastage past the piston rings of the heaviest particles, with a consequential loss of efficiency and economy.

Attempts to prevent this loss on the one hand and to use the heavier fuels on the other have, so far, only met with partial success. Heat from the exhaust generally has been emplond to this end, but it is now apparent that the heat has not been correctly employed in relation to the various functions of the nine; in fact, it has been used in an exactly contrary manner to that which is now shown (by the device to be described by us) to be correct. Hitherto, as the speed of the engine has increased the amount of heat developed and employed has increased proportionally_ • Then as the speed of the engine has decreased, the amount of heat. so developed and employed has also decreased, resulting, as is common knowledge, in the failure of the heavy elements in the fuels to vaporize or remain in suspension at slow engine 'speeds. The net effect has always been a, loss of flexibility.

The third principal defect in carburation has been the inability to use, in high-speed internal-combustion engines, the heaviest hydrocarbons which, if used successfully, should show greater mechanical efficiency for the quantity of fuel used, because these fuels are at once the cheapest and richest in calories. In the distillation of an average sample of crude petroleum, about 10 per cent. of motor spirit of the light and heavy grades (.680 to .720 specific gravity or thereabouts) can be obtained. These sources of motor spirit have been latterly added to by the lighter paraffins (.780 to .820). With the device we are about 06

to describe, it is claimed that there is available as a motor fuel a further. 30 or 25 per cent. (beyond the 10 per cent. referred to) of the crude petroleums, the remaining 55 per cent. consisting of heavy products. This increase in available fuels is tremendons, but it extends even further than appears at first glance, because of the greater heat units in the heavier elements.. Certain oils given off by the distillation of coal, namely, tar oils, and alcohol and peat and shale oils, will also become available as fuel, so that when the invention becomes extensively adopted a widening of the fuel supplies of the world should be rendered possible,

In effect, the Oil Fuel Economizer consists of a combined spray and surface carburetter performing the function of a small gas-producer plant. Mr. Paterson has produced evidence to show that it can be used for any hydrocarbon fuel, such as petrol, kerosene, paraffin, alcohol, tar etc., and the one apparatus can-be adjusted to use any of these fuels alternatively. It is designed for use with modern high-compression engines, and especially for ,self-propelled vehicles running under exacting conditions of load and requiring the maximum of flexibility.

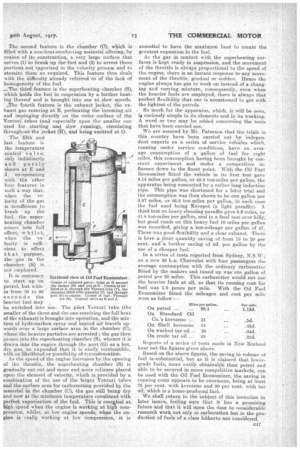

It embodies a combination of features which automatically co-operate in perfect sequence, and in its functioning there is employed the heat derived from the exhaust gm ses. The first of these features is a set of three Venturi tubes, the largest of which is seen at V in the partsectioned illustration, having its jet (K) just showing in the throat of the tube. The air inlet is at A. These Venturi tubes induce the suction velocity in inverse ratio to the speed of the engine, so that velocity of the charge may remain, as near as is practicable, constant in its initial lift at all speeds of the engine. The second feature is the chamber (0), whieh is filled with a non-heat-conducting material offering, by reason of its construction, a very large surface that serves (1) to break up the fuel and (2) to arrest those portions not vaporized in the velocity process and to atomize them as required. This feature thus deals with the difficulty already referred to of the lack of homogeneity of the fuel.

--The third feature is the superheating chamber (S), which holds the fuel in suspension by a further heating thereof and is brought into use at slow speeds. ,The fourth feature is the exhaust jacket, the exhaust gas entering at B, preheating the incoming air and impinging directly on the outersurface of the Venturi tubes (and especially upon the smaller oue used for starting and slow running), circulating throughout the jacket (H), and being emitted at 0.

The 'fifth and last feature' is the temperature control valve, only indistinctly and partly shown 'atE and co-operating with the other four features in suet' a way that, when the ye loeity of 'the gas is • insufficient to break up the fuel, • the superheating chamber comes into full effect, av hils t, when the vuo locity . is, sufficient to effect that -purpose, the gas in the chamber (S) is not employed.

It is necessary to start up On petrol, but within from 30 to 60 seconds the heavier fuel may , be switched into use. The pilot Venturi tube (the smaller of the three and the one receiving the full heat of the exhaust) is brought into operation, and the mixture of hydrocarbon spray and heated air travels upwards over a large surface area in the chamber (0), where the heavier particles are arrested ; the gas then passes into the superheating chamber (5), whence it is drawn into the engine through the port (G) as a hot, dry gas, so expanded that it is easily combustible, with no likelihood or possibility oi recondensation.

As the speedof the •engineincreases by,the opening of the throttle,, the superheating chamber (S) is gradually cut out and more and more reliance placed upon the element of velocity, which is. provided by a combination of the use of the larger Venturi tubes and the surface area for carburetting provided by the material in the chamber (C), the gas still being dry and now at the minimum temperature consistent with perfect vaporization of the fueL This is esseatial at, high speed when the engine is working at high compression, whilst, at low engine speeds, when the engine is really working at low compression, it is Sectional view of Oil Fuel Economizer.

Course of exhaust gases: Inlet at It around the jacket (4) and out at O. Courson( air : Inlet at A, through the Venturi tube IV), the ohamber tilled with material (O, and through port ((f) to engine. Course of fuel : Through jet (IC). Control valve at S and J. essential to have the Maximum heat to create the greatest expansion in the fuel. .

As the gas in contact with the superheating surfaces is kept ready in suspension, and the movement of the throttle is always proportional to the sped of the engine, there is an instant response to any movement of the throttle, gradual or sudden. Hence the engine always has gas to work on instead of a changing and varying mixture, consequently, even when the heavier fuels are employed, there is always that perfect flexibility that•one is accustomed to get with the lightest of the petrols.

. So much for the apparatus, which, it -will be seen, ia curiously simple in its elements and in its working. A word or two may be added concerning the tests that have been carried out.

We are assured by MrPaterson that the trials in this country have been. carried out by independent 'experts on a series of service vehicles which, running under service conditions, have an average consumption of a gallon offuel for eight miles, this consumption having been brought by constant experiment and under a competitive influence down to the finest point. With the Oil Fuel Economizer fitted the vehicle in its first test gave 9.14 miles per gallon, or 42.8 ton-miles per gallon, the apparatus being connected by a rather long induction pipe. This pipe was shortened for a later trial and theconsumption was then shownto be one gallon per 9.87 miles, or 46.2 ton-miles per gallon,in each case the fuel used being Keropet (a light paraffin). A third test on heavy cleaning paraffin gave 8.9 miles, or 41.8 ton-miles per gallon, and in a final test over hilly, but good roads on this heavy fuel 10 miles per gallon was recorded, giving a ton-mileage per gallon of 47. There was good flexibility and a clear exhaust.. -There is here a clear quantity saving of from 15 to 20 per cent. ancl'a further saving of 6d. per gallon by the use of a cheaper fuel.

In a series of tests reported from -Sydney, N.S.W., on a new 20 h.p. Chevrolet with four passengers the average consumption with the ordinary carburetter. fitted by the makers and tuned up was one gallon of petrol per 20 miles. This carburetter would not use the .heavier fuels at all, so that its running cost for fuel was 1.5 pence per mile. With the Oil Fuel Economizer fitted the mileages and cost per mile were as follow :- Reports of a series of tests made in New Zealand bear out the figures given above.

Based on the above figures, the saving in volume of fuel is-substantial, but as it is claimed that lowergrade fuels, more easily obtainable than petrol and able to be secured in more compaitive markets, can be used with the Oil Fuel Economizer, the saving in running costs appears to be enormous, being at least 75 Per cent. with kerosene and 90 per rent. with tar oil, which is a home-produced We shall return to the subject of this invention in later issues, feeling sure that it has a promising future and that it will open the door to considerable research work not only in carburation but in the production of fuels of a class hitherto not considered.