ring brakes all ERF ow models

Page 56

Page 59

If you've noticed an error in this article please click here to report it so we can fix it.

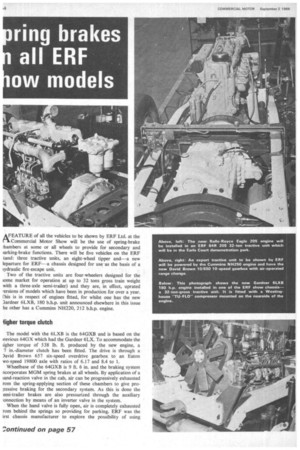

AFEATURE of all the vehicles to be shown by ERF Ltd. at the M.Commercial Motor Show will be the use of spring-brake :hambers at some or all wheels to provide for secondary and )arking-brake functions. There will be five vehicles on the ERF tand: three tractive units, an eight-wheel tipper and—a new leparture for ERF—a chassis designed for use as the basis of a Lydraulic fire-escape unit.

Two of the tractive units are four-wheelers designed for the Lome market for operation at up to 32 tons gross train weight with a three-axle semi-trailer) and they are, in effect, uprated ,ersions of models which have been in production for over a year. ['his is in respect of engines fitted, for whilst one has the new -21ardner 6LXB, 180 b.h.p. unit announced elsewhere in this issue he other has a Cummins NH220, 212 b.h.p. engine.

iigher torque clutch The model with the 6LXB is the 64GXB and is based on the irevious 64GX which had the Gardner 6LX. To accommodate the ligher torque of 538 lb. ft. produced by the new engine, a 7 in.-diarneter clutch has been fitted. The drive is through a )avid Brown 657 six-speed overdrive gearbox to an Eaton wo-speed 19800 axle with ratios of 6.17 and 8.4 to 1.

Wheelbase of the 64GXB is 9 ft. 6 in. and the braking system ncorporates MGM spring brakes at all wheels. By application of a land-reaction valve in the cab, air can be progressively exhausted torn the spring-applying section of these chambers to give pro;ressive braking for the secondary system. As this is done the emi-trailer brakes are also pressurized through the auxiliary :onnection by means of an inverter valve in the system.

When the hand valve is fully open, air is completely exhausted rom behind the springs so providing for parking. ERF was the irst chassis manufacturer to explore the possibility of using

spring brakes, and demonstrations held by the company were reported by COMMERCIAL MOTOR earlier this year. Full approval has not yet been given to the use of these units for parking but this is anticipated shortly. The Show model will have Marks cam and double-roller steering and 10.00-20 tyres all round.

Different engine and transmission The second tractive unit uses the same brake design, frame, front axle, steering, tyre equipment and so on as the 64GXB, but is completely different in respect of power units and transmission components. It carries the designation 64Cu220 and the Cummins NH220 engine drives through an 18 in. clutch and Fuller RTO 910 gearbox to a Centrax CV230 hypoid-bevel rear axle. The Fuller gearbox is a 10-speed, twin-countershaft unit and consists of a five-speed main section with a two-speed section at the rear to give two ratio ranges.

The use of twin countershafts enables the box to be compactly designed, the reduction in tooth load allowing narrower gears. The box is similar to the Fuller RT0915 15-speed unit except that the lowest ratio in the rear section is omitted. Even so the 910 gives an adequate bottom gear. The ratios in the low range are 6.51, 5.1, 4.04, 3.2 and 2.59 to 1, whilst in the higher range—the change is made by air pressure—the ratios are 2.04, 1.59, 1.26, 1 and 0.81 to 1.

Torque capacity of the box is 900 lb. ft., it weighs 626 lb. and measures 30.875 in. long. An interesting point about the Show model is that the engine is inclined to the rear in order to give a straighter prop-shaft run to the Centrax axle. Final drive ratio is 6.143 to 1.

Mainly for overseas Third of the ERF tractive-unit exhibits is a 6 X 4 model—the 66Cu250—and it is designed mainly for overseas use. The Show vehicle is intended for Australia and like the other two models dealt with has a bigger engine than previously used. This is a Cummins NH250 producing 250 b.h.p. at 2,100 r.p.m. and a maximum of 685 lb. ft. torque at 1,500 r.p.m. The drive is through an 18 in.

clutch to the latest David Brown gearbox the 10/650. Like the Fuller this is a two-range box with an air-operated change and there is a five-speed main section and two-speed secondary to give a total of 10 forward ratios. A bottom gear of 8.94 to I is provided and the highest of the 10 ratios is an overdrive of 0.758 to 1.

The rear bogie is a Kirkstail BGT48 with spiral bevel and spur double-reduction axles and two-spring suspension. Capacity of the bogie is 18 tons.

Split system service braking Service braking is by a split system, the front and rearmost axles being on one circuit and the forward rear axle and the semitrailer connection on the other. Secondary and parking brakes are by spring-brake actuators on the rear bogie and these are again controlled by a hand-reaction valve on the steering column which, at the same time as releasing air from behind the springs, pressurizes the auxiliary line to the semi-trailer through an inverted relay valve. Steering is by a cam and double-roller unit and an interesting fitting is air-pressure power assistance made by the American Air-O-Matic Power Steer Corporation. The drag link incorporates the actuating mechanism for the system and feeds air to a cylinder / ram assembly on the other side of the chassis which is connected between the front end of the frame and a second steering arm on the swivel.

The cab on the six-wheeler has been specially developed for export markets. It is called the MV and uses pressed-steel panels

on a steel frame. The interior is lined and the frontal appearai is similar to the standard ERF design, this being achieved by 1 use of plastics mouldings similar to the home market LV cab.

In general, the fourth exhibit by ERF is to a design which been in production for a long time. It is a 68GX eight-wheel tip] for 24 tons gross and has a Gardner 6LX engine and David Bro 657 six-speed overdrive gearbox. The rear axles, however, ; different from the normal ERF eight-wheeler practice in that single-drive rear bogie with two-spring suspension is used.

To improve traction when on difficult sites a system is fitted transfer load on to the driving axle. This consists of air bello located between the axle and the frame side-members. The load the driving axle can be increased by 4 tons and if the load trans system is used when unladen, the trailing axle is lifted clear of 1 ground.

It is interesting that the wheelbase and overhang dimensions the Show chassis are such that the vehicle would be able to run this condition without infringing overhang regulations. Sprit brake actuators are provided at the rear bogie for parking a secondary brakes and the service system is split with independt circuits to the front and driving axles and the second steering a the trailing axles. Power steering is fitted and the cab on the SID chassis will be the ERF 3LV which has an entrance step forward the front wheels.

Petrol-engined Chassis Last of the exhibits on the ERF stand is the new chassis design as a basis for a Simon hydraulic escape platform for fire servici This chassis has a Rolls-Royce B81 235 b.h.p. petrol engine t well back from the front end, behind the front axle. It is mount vertically but does not protrude very much above the frame lel and drives through an ENV 542 synchromesh gearbox to Eaton single-speed rear axle.

The steering is power assisted with an Air-O-Matic air-pressu system as on the export six-wheel tractive unit, and parking a secondary braking are provided by spring-brake actuators at t rear. Tyres are 10.00-20 and a heavy-duty power take-off unit mounted in the transmission line giving a full range of operati speeds through the main gearbox.

ERF is showing a lot of interest in the fire-appliance market the moment for in addition to the special model on the stand the will also be a new fire-fighting appliance chassis on the stand H.C.B.-Angus, bodied and equipped by that company. This h some similarity in mechanical components to the escape mod but has a Perkins V8 170 b.h.p. diesel and a special-design fran The rear axle is a lighter unit and the gearbox is independent mounted. A power take-off is incorporated in the bell housing the engine and driven from a special gear train on the output si of the clutch. As with the escape appliance the drive beyond t power take-off is disconnected when it is in use.