FORD VAN POINTERS.

Page 18

Page 19

If you've noticed an error in this article please click here to report it so we can fix it.

By R. T. Nicholson (Author of "The Book of the Ford").

WE ARE APT to take the commutator for granted. If we give it an occasional regular dose of oil, and see that the fibre ring does not get too far worn, we consider that we are doing our duty by it.

That is not altogether so, as I have lately learnt to my discomfort. ,

133.—Watch Your Commutator.

The other morning.. I was starting out, and—well, I did net start. Nothing would make the engine fire. For some little time before that I had had a bit of trouble with the starting, but I had put tha-t down to some rather heavy oil that had been put into the engine—when my back was turned—instead of the light oil that I always use. I got the engine started by running the car down a .steepish hill. The firing was perfect directly the van

had way on' and continued so till I stopped again. When I tried to get the engine going once again, no —no—no! There was no friendly hill handy, so I could not run the vehicle along for a, start. Handlegrinding resulted in one or tWo. encouraging spits, butthat was all.

I thought hard. Carburation was all right, as was shown by the flooding. I knew the coil tremblers were all right, for I had trimmed them and adjusted the tensions to a nicety. It was riot a case of a short, far all. the wires tould not have shortened at once.

Query commutator trouble? Itook the commutator

cover off—fibre a bit worn, but good, enough. I felt inside—roller all " sloppy: ' What was that on the

engine, pan, near the commutator 7—A pin—the pin

that acts as a pivot for the roller arm (clearly shown in the illustration). There was no bearing for the

roller arm. I put it back to serve temporarily—of course it would not" stavput " ; I knew that—and the engine fired at once, taking me, with only one "peter out," to a garage. There a spare brush wasput en.

An interesting case. You see why theiengine fired perfectly when it once.-got running. The roller was still

" sloppy, ' but centrifugal force sent the roller out against the contacts. You see why she wouldeiot fire once the engine stopped—I could not get enough speed on the engine by -turning the starting handle to throw the roller outwards by centrifugal force.

All of which goes to show that it does not do to take the commutator for granted for ever and ever. Off with the cover every now and again, and feel for trouble. You cannot see the commutator " works " unless you take your radiator off; but you can feel. Everything ought to be nice and tight. Of course, if you press the arm outwards against the pull of the spring, you will feel it give ; but nowhere else should there be any slack, give, or looseness. When I felt,

I felt the looseness of the arm on its pin at once, and knew what the trouble was.

The trouble is not common, but it does happen. It is wonderful, by the way, how the Ford commutator goes on working when there is any amount of loeseness at the various friction points—always provided there is no actual breakage.

134.—Some Tyre Valve Tips.

rumialfP

-AL?

f Am, Fig.. 497 .— The Schrader valvein detail.

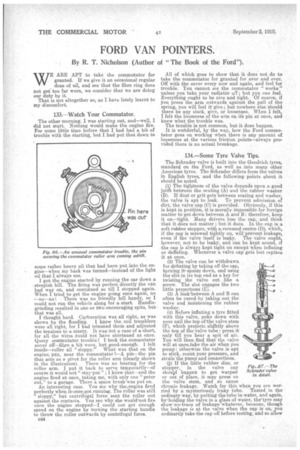

The Schrader valve is built into the Goodrich tyres, standard on the Ford, as well as into many other American tyres. The Schrader differs from the valves in English tyres, and the following points about it should be noted.

(1,1 The tightness of the valve depends upon a good jout between the seating (A) and the rubber washer (B). If dust or grit gets between seating and washer, the va,lve is apt to leak. To prevent admission of dirt, the valve cap (C) is provided. Obviously, if this is.kept in position, it is morally impossible for foreign matter to get down between A and B: therefore, keep it on—tight. Many drivers lose the cap, and think that it does not matter ; but it does. In the cap is a soft rubber stopper, with a. recessed centre (D), which, if the cap is screwed tightly on will prevent leakage, even if the valve itself is leaky. The valve ought, however-, not to be leaky, and can be kept sound, if --the cap is always kept tight on except when inflating or defiding. Whenever a valve cap gets lost replace it at once.

(2) The valve can be withdrawn for deflating by taking off the cap, terning it upside down, and using the slot in its top end as a key for twisting the valve out like a screw. The slot engages the two little projections (E).

(3) A Ieaklbetween A and B can often be cured-by taking out the valve and moistening the rubber washer.

(4) Before inflating a tyre fitted with this valve, poke down with your nail the top of the valve-stem (F), which projects slightly abeve the top of the valve tube: press it only till you bear a spit of air. You will then find that ale valve will at ence,take the air when you pump: otherwise the valve is apt to stick, resist your pressure, and strain'the pump and connections.

() If thelittle rubber disc, or stopper, in the valve cap should happen to get warped • or out of place, it may press on the valve stem, and so cause chronic leakage. Watch for this when you are worried by a mysteriously leaky tube. Tested in the ordinary way, by.putting the tube in-water, and again, bjeholding-the valve in a glasii, of water, the'tyre may

shew'no,trace of leakage -whatever, because, though the leakage is at the valve When the cap is on, you ordinarily take' the cap off before testing, and so allow the valve to seat properly, till you put again—as you do later, after the test. the cap on

135.—Adjusting the Slow Speed.

-Adjustment of the slow speed entails opening up. Take the screws out of the transmission cover door —the plate under the 'footboards—and you will see into the transmission.

Do not drop anything, screws, tools, nuts, split • pins, or what not, into the opening left by removal of the transinissien cover door. If you do, it will fall down into the mechanism where it must on no account be left, because it would foul something, or short-circuit the magneto, and the only way of getting it out would be to remove the whole of the transmission cover, which is quite a big job. Therefore, go carefully to work when the door is off: and it is a good tip to tie a yard. or so of string to any tools you may need to use, so that the string,may trail well outside the cover : then, if one drops in, you can pull it back again.

With the transmission cover door off, you will see three shafts, each with a spiral spring round it. It is the middle one with which you are concerned. Near its left-hand end, you will see a nut on it. Turn that nut clockwise for a turn or so. (There is no means of locking this nut after adjustment : it is unnecessary to lock it, because the pressure of its spiral spring keeps it in position.) Then try the effect on the road, again being careful to get prompt, smooth response on the one hand and no dragging on the other. (See Fig. 88.) In adjusting these three bands, foot brake, reverse, and slow speed, get each band rightly adjusted before you tackle the adjustment of another. Do not take them all three up before you test on the road : because, if you do, and there are then signs of dragging, you will not know which band is responsible for it. Therefore get each band right, as shown by actual test, and then tackle the next.

When you have the cover door off, you can study the action of all three pedals.. Do so. You will see that when you press any pedal (which you can do for present purposes by hand), a band is made to grip a drum tightly. The actual movement of the band is very slight indeed, but it is enough when its adjustment is right. The movement is so slight that you may be deceived : when the adjustment is loose, may quite well seem that the band is sufficient closely adjusted already, and that it would be ove doing it to take it up. But in point of fact, the roa test is the only right test : do not trust to eyesight in this matter. Even when the bands are very slack, they will seem to be in contact, or all but in contact, with their drums. So "try out" on the road.

136.—Split-pins which can be Replaced by Washers.

In Pointer 129, in which I dealCivith the removal cf the transmission cover to give access to the gearing and brake bands, I referred to the split-pinning by which the nuts are secured in the standard assembling. The first time I take the transmission cover off, I say " Good-bye-e-e-e " to those split-pins, for when I replace the nuts I do not split-pin them on, but pi t under each nut a businesslike spring-washer, which s quite good enough to keep its nut from turning. t would not do, of course, to have the nuts turning sl on their own-round the transmission cover, for th t would mean chronic leakage of oil and you do not want that, for it would be wasteful and might be miSchievous. I will guarantee that you will find the spring-washer arrangement perfectly satisfactory fer the purpose in view.

137.—A Caution concerning Split-pins.

But do not jump to the conclusion from what I have just said that a spring-washer will replace a split-pin at any ether point. At nearly every other point where a split-pin is the standard fitting, that split-pin must be on duty. A spring-washer would be no substitute: it would only be a makeshift—and a had one at that. For instance, I would never trust anything but a split-pin in an engine nut or in a back-wheel nut—or indeed anywhere where safety or security depended on "staying put." But at the transmission cover there is no strain to speak of : safety is not dependent on the nuts remaining tight; and, in point of fact, spring-washers do and will keep the joint good. • And, on top of all this, if there happens to be any leakage round the joint at any point, you are bound to notice it, and can tighten up accordingly.

138.—Choked Carburetter.

I have very little patience with clrivers who get into trouble with a choked carburetter. It ought not to get choked. Very little care on three points will prevent it :— (1) Always strain your petrol (or benzole) when filling up. If you have, nothing more handy (the garage funnel gauze being open to suspicion—and dirt) use a handkerchief, or any clean rag as a strainer. (2) Regularly ilrain your sediment bulb—which is there to catch the dirt, and which will catch it, and let it out again, when required. If, however, you never scavenge it, it will let the filth overflow into the pipe to carburetter, and then there will he • trouble. Do not forget that this bulb traps water as well as solid dirt, and that the water sinks to the bottom of the bulb, whence it can be withdrawn hy turning on the tap. (3) Regularly drain your carburetter by means Of the tap which is rather inconveniently placed under it, where it is had to get at. Nevertheless, yciu must get at it from time to time, to let out whatev r sediment has overflowed from the sediment bulb.

Take these three simple precautions, and you oug never to be held up on the road with a choked ca buretter.