SIMPLE EXPEDIENTS FOR BIG JOBS.

Page 75

If you've noticed an error in this article please click here to report it so we can fix it.

Some Useful Contributions from Our Driver and Mechanic Readers.

Tinning a Large Drum-in a Small Lathe.

WHEN a brake drum has to be turned inside to remove a ridge that has formed it is not often convenient to find a lathe with a faceplate sufficiently large to permit bolts to be employed outside the drum, so some means of holding the drum must be improvised.

A suggestion is sent us by a reader from Blackburn (whose name we should like to know) who had this problem before him, and accomplished the job in the following manner.

The drum in this case was one with external bosses through which bolts were used to unite it to its wheel. The drum was 20 ins, in diameter, and the largest faceplate he had access to was only 14 ins. in diameter, so some means bad to be devised for holding the brake ring, as, having no web, it was impossible to hold it to the faceplate without some extension of the latter. Us therefore bolted eight pieces of 2-in. by Fin. iron, 10 ins. long, to the faceplate, as shown in the sketch. At the ends of these pieces he drilled holes to suit the holes in the drum, inserted suitable bolts, and seems to have made a very satisfactory job of it.

In cases where there is a web to the drum it is often possible to drill holes so that bolts can be put through them and through the holes or slots of the faceplate. so that bolts can be used to hold the job to the faceplate. These holes can be tapped and filled in with plugs, if deemed necessary, when the truing is finished,

Removing Ball Pins.

OUR attention is drawn by " A.C.," of Nottingham, to a small article by -".T.S.," of Edinburgh, entitled "Removing Steering Arm Ball Pins," which appeared in a recent issue of this journal.

Instead of using a lever on block, as in his illustration, "AC." finds it much more satisfactory to put the block directly under the ball pin to be removed and to drive a steel wedge between it and the bottom end. of the bail pin, giving the arm a sharp tap downwards with the hammer.

As a rule these pins are very obstinate to remove if not taken in hand properly, but the above method makes a certainty of removal nearly every time and does away with the need for an assistant on the job.

How to Test Radiators.

RADIATORS are a source of trouble

in many instances. states " W.ENir.," of Shefford, as leaks continually occur. All rubber joints should be frequently examined, as rubber perishes, and such joints are bound to go in time.

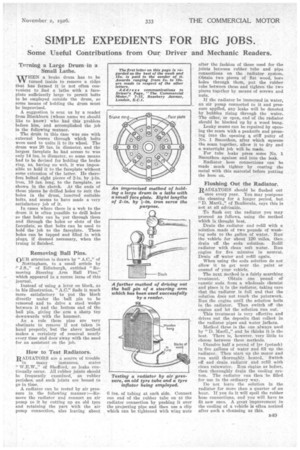

A radiator can be tested by air pressure in the following manner :—Remove the radiator and connect an air pump to it by cutting up an old tyre and retaining the part with the air pump connection, also leaving about

6 ins, of tubing at each side. Connect one end of the rubber •tube on tel the radiator connection by pushing it over the projecting pipe and then use a clip which can be tightened with wing nuts

after the fashion of those used for the joints between rubber tube and pipe connections on the radiator system. Obtain two pieces of flat wood, bore holes through them, put the rubber tube between these and tighten the two pieces together by means of screws and nuts.

If the radiator be immersed in water, an air pump connected to it and pressure applied, any leaks will be denoted by bubbles rising through the water. The other, or open, end of the radiator should be blocked up by a wood bung.

Leaky seams can be repaired by opening the seam with a penknife and pressing into the opening a stiff putty of No. 1 Smoothon, after which squeeze the seam together, allow it to dry and a watertight job will be made.

For tube leaks press some No. 1 Smoothon. against and into the leak.

Radiator hose connections can he made much tighter by coating the metal with this material before putting the hose on.

Flushing Out the Radiator.

RADIATORS should be flushed out once every year. You may postpone the cleaning for a longer period, but "D. MacG.," of BealSecula, says this is not at all advisable.

To flush out the radiator you may proceed as follows, using the method which is thought best.

Drain the radiator and refill with a solution made of two pounds of washing soda to the gallon of water. Run the vehicle for about 120 miles, then drain off the soda solution. Refill radiator with clean • soft water. Rim engine for five minutes in neutral. Drain off water and refill again.

When using the soda solution do not allow it to get near the paint or enamel of your vehicle.

The next .method is a fairly searching treatment. Obtain One pound of caustic soda from a wholesale chemist and place it in the radiator, taking care that the radiator is full and that the solution does not touchthe paintwork. Run the engine until the solution boils in the radiator. Then switch of the engine and let the solution ran out.

This treatment is very effective and drives out the deposits that collect iii the radiator pipes and water jackets.

Method three is the one always used by "D. MacG.," and he thinks it is the best. There is, however, very little to choose between these methods.

Dissolve half a pound of lye (potash) in five gallons of water and fill up the radiator. Then start up the motor and run until thoroughly heated.. Switch off and drain radiator and refill with clean rainwater. Run engine as before, then thoroughly drain the cooling system. The radiator can then be filled for use in the ordinary way.

Do not leave the solution in the radiator for more than a quarter of an hour. If you do it will spoil the rubber hose connections, and you will have to fit new ones. A great improvement in the cooling of a vehicle is often noticed after such a cleansing as this.