The Evolution of Modern Driving Chains.

Page 12

Page 13

Page 14

If you've noticed an error in this article please click here to report it so we can fix it.

(Continued from page 95.) In our issues of October 12th and 19th we traced the evolution of the motorcar driving chain from that of the early "

Kangaroo" bicycle up to practically the present day. The third and concluding portion was unavoidably held over last week. It has been shown that the motor chain is only an enlargement of the bicycle chain, which had already attained a high degree of perfection. Roller chains, of the several different forms now used, have been illustrated, and we should like to add that the " special " motor chain, illustrated in Fig. 9 (page 94), where the bushes are integral with the inner side plates, is made by the Coventry Chain Company, which makes a particular feature of this class of work. This company adopted the word " special " to distinguish this chain from its standard chain (depicted in Fig. 8, page 79).

The two previous sections of this article have led to some correspondence, particu larly with regard to the stretching of roller chains. All who have watched the wear of these chains will have noticed that, however accurately they may be made, there is always an initial stretch, noticeable from the very first day of use. The Coventry Chain Company, in order to prevent the rollers from immediately riding up the teeth, as is the case when the pitch length increases, has adopted a form of tooth with a somewhat flatter bottom than that illustrated in Fig. it (page 94). This allows the rollers partially to adjust themselves as they stretch, and postpones the inevitable mounting of the teeth.

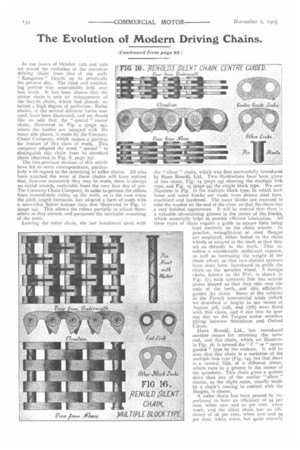

Leaving the roller chain, the last instalment dealt with the " silent " chain, which was first successfully introduced by Hans Renold, Ltd. Two illustrations have been given of this chain, Fig. 14 (page 95) showing the multiple link type, and Fig. 15 (page 95) the single block type. We now illustrate in Fig. T6 the multiple block type, in which both inner and outer blocks are made from drawn steel bars, machined and hardened. The outer blocks are recessed to take the washer on the end of the rivet, so that the chain has a very finished appearance. It will be noticed that there is a valuable oil-retaining groove in the centre of the blocks, which materially helps to provide efficient lubrication. All these types of chain require a guide to ensure their being "kept correctly on the chain wheels. in practice, wrought-iron or steel flanges are employed, either bolted to the chain

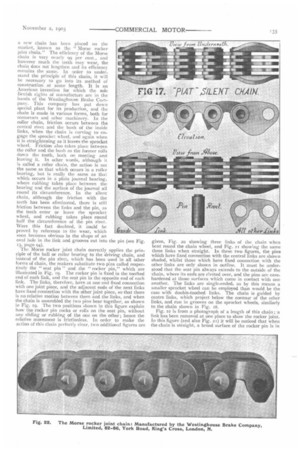

wheels or secured to the shaft so that they act as shrouds to the teeth. This involves a considerable additional expense, as well as increasing the weight of the chain wheel, so that two distinct systems have since been introduced to guide the chain on the sprocket wheel. A foreign chain, known as the Pint, is shown in Fig. 17; each alternate link has outside plates shaped so that they ride over the ends of the teeth, and this efficiently guides the chain. Some of the vehicles in the French commercial trials (which we described_ at length in our issues of August 3rd, moth, and 17th) were fitted with this chain, and it can now be seen any day on the Turg-an motor omnibus plying between Streatham and Oxford Circus.

Hans Renold, Ltd., has introduced another means for attaining the same end, and this chain, which we illustrate in Fig. 18, is termed the " C " or" centre guided" type by the makers. It will be seen that this chain is -a variation of the multiple link type (Fig. 14), but that there is a central link, of a different shape, which runs in a groove in the centre of the sprockets. This chain gives a quieter drive than any of the earlier " silent" chains, as the slight noise, usually made by a chain's coming in contact with the flanges, is absent. • A roller chain has been proved by experiment to have an efficiency of 94 per cent. when new and 92 per cent. when worn, and the silent chain has an efficiency of 96 per cent. when new and 95 per cent. when worn, but quite recently

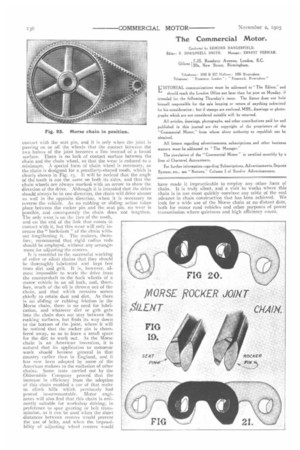

a new chain has been placed on the market, known as the " Morse rocker joint chain." The efficiency of the Morse chain is very nearly 99 per cent., and however much the teeth may wear, the chain does not lengthen and its efficiency remains the same. In order to under_ stand the principle of this chain, it will be necessary to go into its method of construction. at some length. It is an American invention for which the sole British rights of manufacture are in the hands of the Westinghouse Brake Company. This company has put down special plant for its production, and the chain is made in various forms, both for motorcars and other machinery. In the roller chain, friction occurs between the central rivet and the bush of the inside links, when the chain is curving to engage the sprocket wheel, and again when it is straightening as it leaves the sprocket wheel. Friction also takes place between the roller and the hush as the former rolls down the tooth, both on meeting and leaving it. In other words, although it is called a roller chain, the action is not the same as that which occurs in a roller hearing, but is really the same as that which occurs in a plain journal bearing, where rubbing takes place between the bearing and the surface of the journal all round its circumference. In the silent chain, although the friction with the teeth has been eliminated, there is still friction between the links and the pin, as the teeth enter or leave the sprocket wheel, and rubbing takes place round half the circumference of the pin rivet. Were this fact doubted, it could be proved by reference to the wear, which soon becomes obvious in the shape of an oval hole in the link and grooves cut into 13, page 94).

the pin (see Fig.

The Morse rocker joint chain correctly applies the principle of the ball or roller bearing to the driving chain, and instead of the pin rivet, which has been used in all other forms of chain, the makers substitute two pins called respectively the "seat pin " and the " rocker pin," which are illustrated in Fig. 19. The rocker pin is fixed in the toothed end of each link, and the seat pin in the opposite end of each link. The links, therefore, have at one end fixed connection with one joint piece, and the adjacent ends of the next links have fixed connection with the other joint piece, so that there is no relative motion between them and the links, and when the chain is assembled the two pins bear together, as shown in Fig. 19. The two positions shown in this figure explain how the rocker pin rocks or rolls on the seat pin, without any sliding or rubbing of the one on the other; hence the relative movement is frictionless. In order to make the action of this chain perfectly clear, two additional figures are

given, Fig. 20 showing three links of the chain when bent round the chain wheel, and Fig. 21 showing the same three links when straight. In these two fig-ures, the pins which have fixed connection with the central links are shown shaded, whilst those which have fixed connection with the other links are only shown in outline. It must be understood that the seat pin always extends to the outside of the chain, where its ends are riveted over, and the pins are casehardened at those surfaces which come in contact with one another. The links are single-ended, as by this means a smaller sprocket wheel can be employed than would be the case with double-toothed links. The chain is guided by centre links, which project below the contour of the other links, and run in grooves on the sprocket wheels, similarly to the chain shown in Fig. IS.

Fig. 22 is from a photograph of a length of this chain; a link has been removed at one place to show the rocker joint. In this figure (and also Fig. 21) it will be noticed that when the chain is straight, a broad surface of the rocker pin is in

contact with the seat pin, and it is only when the joint is passingon or off the wheels that the contact between the Iwo halves of the joint becomes a line instead of a broad surface. There is no lack of contact surface between the chain and the chain wheel, so that the wear is reduced to a minimum. A special form of chain wheel is necessary, as the chain is designed for a peculiarly-shaped tooth, which is clearly shown in Fig. 23. it will be noticed that the angle of the tooth is not the same on both iLs sides, and that the chain wheels are always marked with an arrow to show the direction of the drive. Although it is intended that the drive should always be in one direction, the chain will drive almost as well in the opposite direction, when it is necessary to reverse the vehicle. As no rubbing or sliding action takes place between the rocker pin and the seat pin, no wear is possible, and consequently the chain does not lengthen. The only wea,. is on the face of the tooth,

and on the end of the link that comes in contact with it, but this wear will only increase the" back-lash " of the chain without lengthening it. The makers, therefore, recommend that rigid radius rods should be employed, without any arrangement for adjusting the centres.

It is essential to the successful working of roller or silent chains that they should be thoroughly lubricated and kept free from dirt and grit. It is, however, almost impossible to work the drive from the countershaft to the hack wheels of a motor vehicle in an oil bath, and, therefore, much of the oil is thrown out of the chain, and that which remains serves chiefly to retain dust and dirt. As there is no sliding or rubbing friction in the Morse chain, there is no need for lubrication, and whatever dirt or grit gets into the chain does no; stay between the rocking surfaces, but finds its way down to the bottom of the .joint, where it will be noticed that the rocker pin is chamfered away, so as to leave a small space for the dirt to work out. As the Morse chain is an American invention, it is natural that its application to motorcar work should become general in that country earlier than in England, and it has now been adopted by some of the American makers to the exclusion of other chains. Some tests carried out by the Oldsmobile Company proved that the increase in efficiency from the adoption of this chain enabled a car of that make Lo climb hills which previously had proved insurmountable. Motor engineers will also find that this chain is eminently suitable for workshop driving, in preference to spur gearing or belt transmission, as it can be used when the short distances between centres would prevent the use of belts, and when the impossibility of adjusting wheel centres would have made it impracticable to employ any other form of chain, it is truly silent, and a visit to works where this chain is in use must quickly convince any critic of the real advance in chain construction that has been achieved. We look for a wide use of the Morse chain at no distant date, both for motor road vehicles and other purposes of power transmission where quietness and high efficiency count.