All the models in the Transcontinental range use twinplate clutches

Page 33

Page 34

Page 35

If you've noticed an error in this article please click here to report it so we can fix it.

from Dana Spicer although the diameters vary depending on whether the engine is turbocharged or naturally aspirated. A 356mm (14in) diameter plate is used for the 240-horse engine with a larger 394mm (15.5in) component for the remainder. The clutches are self adjusting and have angled pressure springs which Dana Spicer claims give a constant pedal load as the pedal is depressed.

The standard gearbox for the range is the 9-speed RT9509C from Fuller with the 13-speed RT09513 available as an option, both units being of constant-mesh design. Power take-off points are provided at the side and underneath on both gearboxes.

Ford has specified a singlereduction-type rear axle from Rockwell for the new trucks, the crown wheel of which measures 500mm (19.6in) in diameter. On the double-drive bogie of the 6x4 models differential locks are provided bcth between the axles and across them.

Louisville frame

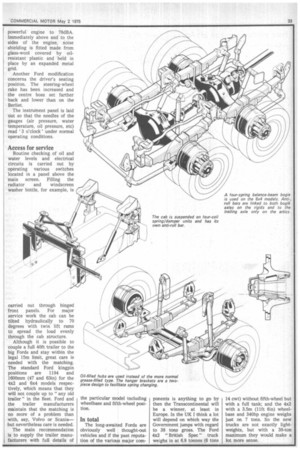

The frame is about the only main component to be of Ford design and construction. All the frames for the different models in the range are based on the American heavy-duty trucks, the Louisville built Lseries, and are of parallel flattopped construction, being bolted together with high-tensile bolts and hardened steel washers. Ford claims that the specified steel for the frames is so tough with its yield strength of 758,500kN/sqin (110,000 psi) that no flitching is required on any frame.

The front axle is unusual, featuring oil-rather than grease-filled hubs which Ford claims minimise wear by starting lubrication immediately the truck sets off whereas grease requires time to reach operating temperature. The axle is of I-beam construction forged from carbon manganese chromium steel and is common to all the Transcontinental models in the range.

The suspension is by lowrate leaf springs fore and aft with telescopic dampers on all axles. Two leaves from each spring are wrapped around the spring bush as a safeguard against one of them breaking and the hanger brackets are of two-piece design with the plate adjacent to the frame being a casting and the Y-shaped brace a forging. This Y-piece is removable for spring changing which should eliminate the need for burning out old shackle pins. A four-spring balance beam bogie is used on the 6x4 models. Anti-roll bars are linked to both bogie axles on the rigids and to the trailing axle only on the artics. All the models have power steering as would be expected although Ford has used a split system giving power assistance to both stub axles by means of a conventional integral power-steering unit in conjunction with a slave hydraulic ram. Ford claims that this arrangement allows the hydraulic pressure in the whole system to be lower than with a single-ram system with a consequent reduction in oilseal leakages.

EEC braking system

The braking system for the Transcontinental is claimed to meet all current EEC legislation. Basically a full-air twoline system, it has options available which adapt it to the British and French three-line systems.

The service brake is a split system, one circuit of which serves the front axle, with the other serving the rear axle or axles, and full trailer braking is retained in the event of one circuit failing. A slide-valvetype exhaust brake is standard equipment.

The emergency brake works on the system of gradually releasing air from the springbrake units on the tractive unit and applying the trailer brakes. The parking brake works on the same system but on the tractive unit only.

All the models in the range are fitted with 394 x 200mm (15.5 x 8in) brake drums on the front axle and 394 x 175mm (15.5 x 71n) at the rear. This combination gives a total frictional area of 5160sqcm (801sqin) for the two-axle vehicles and 7568sqcm (1175sqin) for the three-axle models.

If we assume an average braking area for a typical tandem-axle trailer of 6840sqcm (1060sqin) this will give a braking capacity of 369sqcm/tonne (58sqin/ton) for the two-axle machines and 443sqcm/tonne (70sqin/ton) for the three-axles, both at 32 tons gross. Ford has standardised on load-sensing valves for all the model range.

A thermoplastic material has been specified for the brake lines. Ford says it is more resistant to fatigue than metal while being easier to shape ; the material also allows a smaller bore tubing to be used, which in turn gives a more rapid pedal response.

Cab by Berliet

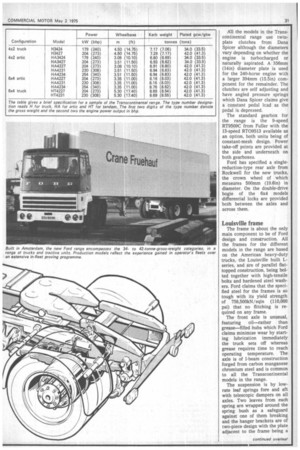

To say that Ford uses the Berliet cab is true, but it is rather simplifying the issue. The basis of the Transcontinental cab is indeed the Berliet but Ford makes many modifications including the fitting of a glassfibre skirt below the cab waist level as the cab is mounted far higher than on a Berliet. A sleeper cab shell is standard (there is no "short" cab available) and it is made in pressed steel above the waist while the glassfibre panels are painted white whatever the body colour.

Gone are the days of "You can have it any colour you like—so long as it's black!" The metal cab is first phosphated, electrocoated and primed before being sprayed in a choice of 10 colours which sound as though they were named by the car division : Diamond white, Sunset red, Bitter green and so on to Sebring red and Cargo grey. Because the cab is so high three entry steps are necessary. They have been set at a slight angle to the vertical so the driver can see where his feet are going when getting out of the cab.

Extensive noise-reduction modifications have been made to the Berliet cab which the Ford engineers claim have brought the interior noise level down under the worst conditions with the most powerful engine to 78dBA. Immediately above and to the sides of the engine, noise shielding is fitted made from glass-wool covered by oilresistant plastic and held in place by an expanded metal grid.

Another Ford modification concerns the driver's seating position. The steering-wheel rake has been increased and the centre boss set farther back and lower than on the Berl iet.

The instrument panel is laid out so that the needles of the gauges (air pressure, water temperature, oil pressure, etc) read ' 3 o'clock' under normal operating conditions.

Access for service

Routine checking of oil and water levels and electrical circuits is carried out by operating various switches located in a panel above the main screen. Filling the radiator and windscreen washer bottle, for example, is carried out through hinged front panels. For major service work the cab can be tilted hydraulically to 70 degrees with twin lift rams to spread the load evenly through the cab structure.

Although it is possible to couple a full 40ft trailer to the big Fords and stay within the legal 15m limit, great care is needed with the matching. The standard Ford kingpin positions are 1194 and 1600mm (47 and 63in) for the 4x2 and 6x4 models respectively, which means that they will not couple up to "any old trailer" in the fleet. Ford and the trailer manufacturers maintain that the matching is no more of a problem than with, say, Volvo or Scaniabut nevertheless care is needed.

The main recommendation is to supply the trailer manufacturers with full details of the particular model including wheelbase and fifth-wheel position.

In total

The long-awaited Fords are obviously well thought-out vehicles and if the past reputation of the various major corn ponents is anything to go by then the Transcontinental will be a winner, at least in Europe. In the UK I think a lot will depend on which way the Government jumps with regard to 38 tons gross. The Ford 4x2 "British Spec" truck weighs in at 6.8 tonnes (6 tons 14 cwt) without fifth-wheel but with a full tank; and the 4x2 with a 3.5m (lift ein) wheelbase and 340hp engine weighs just on 7 tons. So the new trucks are not exactly lightweights, but with a 38-1on maximum they would make a lot, more sense.