For DRIVERS MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF TEN SHILLINGS is awarded each week to the render of the best letter which we publish on this page,' all others are paid for at the rateof a penny a line, with an allowance for photographs: All 7y,tes are edited before being published. Mention your employer's name, in confidence, as'evidence of good faith, Address, D., M. and P., • The Commercial Motor," 7-15, Rosebery Avenue', London, E.C. .1.

Lamps Alight— .

Light your lamps at 8.49 in London, .9.49 in Edinburgh, 9.9 in Newcastle, 9.8 in Liverpool, 9.0 in Birmingham, 8.59 in Bristol, and 9.50 in Dublin.

Running with a Damaged Injector.

The sender of the following 'conzmunication has been awarded the 10s. prize thiS week.

[1852] "A.W." (Dewsbury) writes :—" I had an unusual experience recently on a steam wagon, the injector of which suddenly began to give trouble. The first incident was the blowing back of-steam past the check valve of the injector when the latter was shut down. I immediately slopped and endeavoured to ascertain the source of the trouble. I surmised that a little piece of dust, or scale was holding the check valve off its seating. I therefore screwed up the plug valve, thus isolating the injector from the boiler, and took out the cheek valve. Everything-appeared, however, to be all right. The top of the seating and the face of the valve were quite clean. There did not seem to be any reason why the steam should blow back. I therefore replaced the valve, opened the plug valve, and tried again, with, to my surprise, the same result. I then concluded that the trouble must lie with the steam inlet valve fro ni the boiler, or, alternatively, that the steam, by some means or other, was getting underneath the check valve •seating, which was of the loose, renewable type. I tried the boiler valve, and this, on examination, proved to be quite steam tight. I then turned my attention to the renewable seat of the check valve of the injector, trying to/ screw it down so that I could ascertain if perchance it had worked a little loose. To my dismay, I discovered that it had broken oir entirely just beneath the top flange of the seating.

• "Here I was, many miles from home, no new seating valve available, and apparently with an injector entirely disabled. It struck me, however, that there was just a chance that it might be possible to get water into the boiler without there being a check valve in the injector.. I almost rejected this idea so soon as it had formed, and I daresay that, without exception, every steam wagon driver who reads this will do the same : many will laugh at the bare idea. However, I determined to make an attempt.

"I commenced operations by once more isolating the injector from the boiler, screwing down the plug valve tight. I .then turned on the water, and afterwards, steam; to get the injector to pick up water, so that., the connection to the boiler being dosed, the water ran out from the overflow pipe. Then, care fully opening the plug valve little by little, I managed to coax the injector to force water to the boiler, with very little waste. down the overflow pipe. So far, so good. I had got the injector to work. What was going to be the procedure when I desired to stop it I found, however,_that it could be done with very little trouble. The first operation was to shut off the plug valve, and then the steam valve, the latter being closed as quickly-as possible. Naturally there was a blow-back of steam for a minute or so„as can only be expected without a check valve, but by repeating this procedure I was able to get home in good order. "While writing, another useful tip occurs to me. It sometimes happens that the suction pipe from tank to injector may have a little blow hole in it. Or sometimes a small hole may wear, in this pipe. As a consequence, the injector ten& to draw air rather than water. On one occasion, when meeting with . trouble a this kind, I happened to have a small piece of insulation tape, such as petrol lorry drivers are well acquainted with, in my tool kit. I wound this round and round the pipe over the bole, and this repair held good for many weeks."

Repairing a Daimler Crankcase.

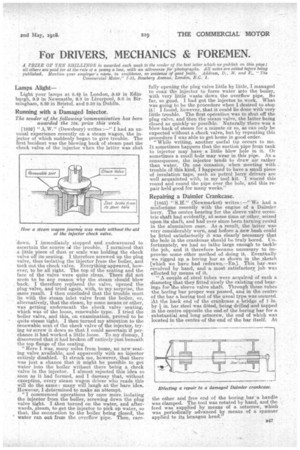

[1883] " S.1-r." (Newmarket) writes :—" We had a misfortune recently with the engine of a Daimler lorry. The centre bearing for the sleeve valve eccentric shaft had evidently, at some time or other, seized upon its shaft, and had ever since been turning round in the aluminium case. As a result, the latter was very considerably worn, and before a new bush could be fitted satisfactorily it was clearly necessary that the hole in the crankcase should be truly bored. Unfortunately, we had no lathe large enough to tackle the -job, and it therefore became necessary to improvise some other method ofdoing it. Eventually we rigged up aboring bar as shown in the ,sketch [which we have had redratin.—En.]. This bar was revolved by hand, and a most satisfactory job was effected by means of it.

• "A couple of. steel tubes were acquired of such a diamete that they fitted nicely the existing end bearings for the 'sleeve valve shaft.. Through these tubes the boring bar proper was passed, and in the centre of the bar a boring tool of the usual type was secured. At the back end of the crankcase a bridge of 1 in.

by in bar gteel was fitted, being drilled and tapped in the centre opposite the end of the boring bar for a substantial and long setscrew, the end of which was located in the. centre of the end of the bar itself. At