Automatic gearboxes make more sense in trucks than any other

Page 38

Page 39

If you've noticed an error in this article please click here to report it so we can fix it.

class of vehicle, and IF has brought that goal a step closer with a full auto version of its AS-Ironic gearbox. Can this technology really replace the clutch pedal? There was only one way to find out...

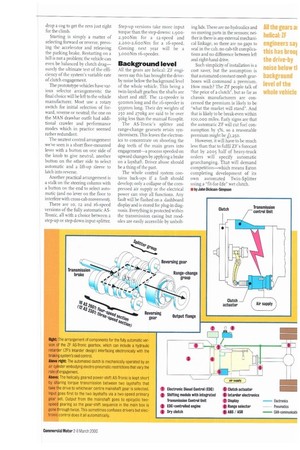

ZF has developed a fully automatic variant of its electronically synchronised AS-Tronic gearbox. The new unit does away with clutch control altogether and could transform the performance and acceptance of automated gearboxes. What ZF has done, in essence, is to automate the clutch action of the AS-Tronic, with which the driver still has to use the clutch for starting and stopping.

Making the leap from semi to fully automatic with a clutched gearbox is a tough job—it entails developing an electronic processor to control the clutch and throttle control accurately enough to cope with everything from climbing steep hills to low-speed manoeuvring and trailer coupling. The ZF engineers soon found that a system that simply compared input and output speeds at the dutch was woefully inadequate: there had to be continual comparison between load demand and available torque.

This is what's so special about the ZF clutch control. It does not simply compare input and output speeds; it also senses the rates of change in those speeds. When pulling away with a heavy load or up a steep hill the engine decelerates rapidly. The ZF electronics sense that in milliseconds, simultaneously easing off the rate of clutch engagement and telling the engine's injection management unit to deliver more fuel and power.

Inevitably, the automated ASTronic only works with engines that have electronic diesel control, but that will soon be universal anyway to comply with exhaust emission limits.

Drawbar rig

Does it work? Yes it does, and very impressively, too. Out of an array of field-trial heavies assembled by ZF we tried a Neoplan coach and an MAN drawbar rig. We drove them uphill and downhill, drove them hard, manoeuvred them slowly. stopped and started.

Within a surprisingly short time the driver's left foot had stopped searching for that non-existent clutch pedal, and when backing an MAN tractor under a semi-trailer to couple it, the automatic clutch control was uncannily human. using a final one-metre sprint to dunk the trailer pin.

On the move the gearchanges are perceptible but smooth and fast. According to ZF timings, main-box changes take o.2sec: range changes take o.3sec. For down changes the double-declutching and engine speed matching are handled automatically with impressive precision. When the going is easy the system automatically skip-shifts.

If the driver thinks he can do better than the electronic brain he can override it by simply flicking the small selector lever—but the shift will be refused if it would cause the engine to overspeed by more than to% (which some operators might feel is verging on the over-cautious). Pressing a button on the selector lever reinstates the automatic operation.

Under manual control the gearshifts are a little brisker, which is welcome on a hilklimb. Also, clever as the electronic processor is, it cannot see a hill coming—but by reverting to manual the driver can drop a cog to get the revs just right for the climb.

Starting is simply a matter of selecting forward or reverse, pressing the accelerator and releasing the parking brake. Restarting on a hill is not a problem; the vehicle can even be balanced by clutch drag— surely the ultimate test of the efficiency of the system's variable rate of clutch engagement.

The protototype vehicles have various selector arrangements; the final choice will be left to the vehicle manufacturer. Most use a rotary switch for initial selection of forward, reverse or neutral; the one on the MAN drawbar outfit had additional crawler and performance modes which in practice seemed rather redundant.

The neatest control arrangement we've seen is a short floor-mounted lever with a button on one side of the knob to give neutral, another button on the other side to select automatic and a lift-up sleeve to latch into reverse.

Another practical arrangement is a stalk on the steering column with a button on the end to select automatic (and no lever on the floor to interfere with cross-cab movement).

There are 10, 12 and i6-speed versions of the fully automatic ASTronic, all with a choice between a step-up or step-down input splitter. Step-up versions take more input torque than the step-downs: 1,9002,3ooNm for a 12-speed and 2,200-2,60o Nrn for a 6-speed. Coming next year will he a 3.000Nm 76-speeder.

Background level

All the gears are helical: ZF engineers say this has brought the driveby noise below the background level of the whole vehicle. This being a twin-layshaft gearbox the shafts are short and stiff The 12-speeder is omm long and the 16-speeder is 953mm long. Their dry weights of 250 and 270kg are said to be over 50kg less than the manual Ecosplit.

The AS-Tronic's splitter and range-change gearsets retain synchronisers. This leaves the electronics to concentrate on shooting the dog teeth of the main gears into engagement—a process speeded on upward changes by applying a brake on a layshaft. Driver abuse should be a thing of the past.

The whole control system contains back-ups if a fault should develop; only a collapse of the compressed air supply or the electrical power can stop all functions. Any fault will be flashed on a dashboard display and is stored for plug-in diagnosis. Everything is protected within the transmission casing but modules are easily accessible by unbolt

ing lids. There are no hydraulics and no moving parts in the sensors; neither is there is any external mechanical linkage, so there are no gaps to seal in the cab, no cab-tilt complications and no difference between left and right-hand drive.

Such simplicity of installation is a cost saver, but the assumption is that automated constant-mesh gearboxes will command a premium. How much? The ZF people talk of "the price of a clutch", but as far as chassis manufacturers are concerned the premium is likely to be "what the market will stand". And that is likely to be break-even within 100,000 miles. Early signs are that the automatic ZF will cut fuel consumption by 5%, so a reasonable premium might be L1,250.

However, it will have to be much less than that to fulfil ZF's forecast that by 2005 half of heavy-truck orders will specify automatic gearchanging. That will demand competition—which means Eaton completing development of its own automated Twin-Splitter using a "fit-for-life" wet clutch.

• by John Dickson-Simpson