NOW A COMMER 8-TONNER

Page 67

Page 68

Page 69

Page 70

Page 71

If you've noticed an error in this article please click here to report it so we can fix it.

Rootes Group Enters Heavy-vehicle Field With an 8-ton Forward-control Goods Chassis: New Cab Available on this, a New 71-ton Chassis and the 10/11and 12-ton Tractive Units: Routes Two-stroke Diesel

By John F. Moon, A.M.I.R.T.E.

no Longer Offered in 7-ton Chassis

ACOMPLETELY new 8-ton forward-control goods chassis for operation at 12 tons I cwt. gross solo weight and a new 71-ton chassis, as well as a smart new cab for these two models, and for slightly modified 10/11and 12-ton tractive units also, are announced today by Comrner Cars, Ltd., Luton, Beds.

Notwithstanding various rumours that have been circulating in the industry for some months about a new Cornrner 8-tonner with a four-cylindered version of the Rootes twostroke diesel engine, the new 8-tonner is quite conventional in design and obviously has generous strength margins.

Also revealed today is the adoption of the Perkins 6.354 horizontal diesel engine as standard equipment in 7-ton chassis, the Rootes two-stroke engine being no longer available in these.

Two versions of the new 8-tonner are available. One, for tipper use, has a wheelbase of 9 ft. 7 in., and an overall length of 16 ft. n, in., whilst the haulage model has a longer wheelbase than any previous C,ommer forward-control goods chassis-15 ft. 7 in.—making it suitable for bodywork up to 21 ft. long, the overall chassis length being 27 ft. 0+ in., measured from the front bumper to the rear of the spare wheel. In the case of both models 9.00-20 (12-140 tyres are standard, with the option of 10.00-20 (12-ply) equipment, and the chassis-cab dry weights are 3 tons 5.5 cwt. for the short-wheelbase chassis and 3 tons 7.25 cwt. for the long model.

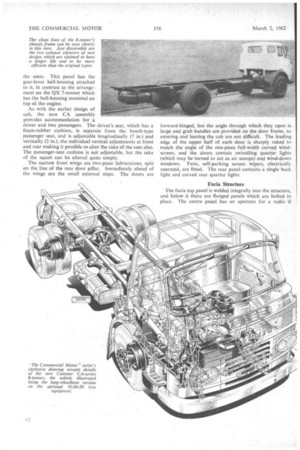

Externally, the most distinctive feature of the new 8-tonner is the cab, which is a completely new Commer design of all-steel construction. In contrast to the 14-year-old QX cab, which will continue to be used on the lighter Cornmer and Karrier forward-control chassis, the new CA cab is virtually a full-width design. Its interior width is 72 in., which is 9+ in. greater than that of the QX design, whilst the internal height measured from floor to roof is 501 in.1+ in. more than that of the QX.

New Cab Design

As with the QX cab, the new CA design has a flat floor for use with horizontal-engined chassis, and it has an integral sub-frame supporting the structure, the floor and the radiator„ The complete assembly is mounted on four widely spaced Metacones, the mounting layout being almost identical to that of the QX cab, which suggests that the cab could well be applied to existing Rootes forward-control chassis at some time in the future.

Spot welding is used almost entirely throughout the assembly of the cab and underframe. The flat floor extends from the seat-box heelboard to the floor of the toe panel and runs from wheel arch to wheel arch. Detachable inspection covers are incorporated in both sides of the floor to give access to chassis parts lying directly beneath, whilst, as with the QX cab, the seat box has two large, hinged panels in its upper surface to give a high degree of engine accessibility.

Both engine-inspection traps may be propped up by means of hinged stays, and additional access to the engine can be obtained by unbolting the centre panel which is between r 1 the seats. This panel has the gear-lever ball-housing attached to it, in contrast to the arrangement on the QX 7-tonner which has the ball-housing mounted on top of the engine.

As with the earlier design of cab, the new CA assembly provides accommodation for a driver and two passengers. The driver's seat, which has a foam-rubber cushion, is separate from the bench-type paisenger seat, and is adjustable longitudinally (7 in.) and vertically (2 in.), the individual vertical adjustments at front and rear making it possible to alter the rake of the seat also. The passenger-seat cushion is not adjustable, but the rake of the squab can be altered quite simply.

The narrow front wings are two-piece fabrications, split on the line of the rear door pillar. Immediately ahead of the wings are the small external steps. The doors are forward-hinged, but the angle through which they open is large and grab handles are provided on the door frame, so entering and leaving the cab are not difficult. The leading edge of the upper half of each door is sharply raked to match the angle of the one-piece full-width curved windscreen, and the doors contain swivelling quarter lights (which may be turned to act as air scoops) and wind-down windows. Twin, self-parking screen wipers, electrically operated, are fitted. The rear panel contains a single back light and curved rear quarter lights.

Facia Structure The facia top panel is welded integrally into the structure, and below it there are flanged panels which are bolted in place. The centre panel has an aperture for a radio if required, a blanking plate being fitted as standard. Accessories, such as a cigarette lighter and screen-washer control, may also be fitted in this centre panel, which is hammerfinished in grey. The layout of the facia is such as to allow the cab to be used with either leftor right-hand-drive chassis. A millboard glove box without lid is incorporated on the passenger side, the corresponding hole on the driving side having the instrument binnacle mounted over it. A glove-box lid is available at extra cost.

The instrument panel is mounted in a near vertical plane for easy reading. Instruments consist of speedometer, odometer (with tenths), temperature and fuel gauges, airpressure gauge, engine blower-pressure gauge, and warning lights for braking-air pressure, coolant temperature, direction indicators, oil pressure, dynamo charging and headlamp main beam. A tachometer is available also. The side and headlamp switch is on a steering-column stalk, and has the horn button in the end of it.

Equipment includes an interior light above the windscreen, a moulded-rubber floor mat, control and fuse boxes readily accessible beneath the facia panel, and full stowage behind the seats for the toolkit, including jack, starting handle (when supplied), tyre lever and wheelbrace.

The external appearance of the new CA cab bears a family relationship to the current Commer 15-cwt. models, although one important styling difference is the use of paired headlamps. .Because of the relatively small size of the radiator grille and the rather high windscreen line, the new cab presents a " solid " appearance when viewed from the front. Self-cancelling, flashing direction indicators, with double-sided 4-in, lenses, are mounted on the sides of the cab as standard equipment. Large exterior mirrors, mounted on rigid, triangulated arms, are a praiseworthy part of the standard specification.

To cope with differing climatic conditions the new cab is fully dust-sealed, with sponge rubber seals fitted around the doors and all panel joints sealed during, or after assembly with a suitable compound. The roof is lined with KB waterproof board, while Flint-Kote bituminized felt sheet is applied to the lower portion of the cab back panel. Fresh-air ventilation is standard, air entering the collector box from a large aperture above the radiator grille, and there is an optional heater kit which includes four demister outlets.

The Chassis

Turning to the several chassis on which the new cab is mounted, prime importance must be attached to the CADY 815 9-ft. 7-in.-wheelbase and CADY 887 15-ft. 7-in.-wheelbase 8-ton models. Both these types are available in chassiscab form, and the short-wheelbase version can be ordered complete with 6-cu.-yd. timber tipping body. The longwheelbase model is available as a chassis with basic front-end panelling.

Both 8-tonners have new chassis frames, the side members of which are 0.28-in.-thick mild-steel pressings with a maximum depth of 9.75 in., and 2.62-in.-wide top flanges, with 3.06-in.-wide bottom flanges. The use of mild steel is an innovation so far as Commer heavy vehicles are concerned, the original 7-tonner, for example, having hightensile-steel main members. The mild-steel frame of this 8-tonner, however, permits a greater degree of flexibility

than is given by the 7-tonner frame, despite the greater side-member depth.

The short-wheelbase chassis has six cross-members, and the long-wheelbase version has eight. In both cases the two foremost members are tubular and are bolted in place, the remaining channel-section members—which have alligator-jaw ends—being riveted, although the spring-hanger brackets are bolted. In plan, the layout of the 8-tonner frames is similar to that of the 7-tonners in that the side members are swept outwards in the area of the cab. Also following 7-tonner practice is the profile of the side members. These start to taper rearwards of the rear-spring front-hanger brackets, the depth at the end of the frame being 4.92 in., the upper flanges being level throughout the length of the frame.

Semi-elliptic Springs

Semi-elliptic springs are employed at front and rear, these being 3 in. wide. The front springs are 57.5 in. long and have nine leaves in the case of long-wheelbase models and 10 leaves on tipper chassis, lever-type dampers being standard in both cases. The rear springs are 54 in. long and have 13 leaves. Six-leaf helper springs are standard.

The front axle assembly has a similar bed to the axle used on 7-tonners, but the king pins and hub bearings are larger and 10-stud hubs are fitted. Similarly, the standard singlespeed rear axle is akin to that of the 7-tonner, except for the 10-stud hubs. The load rating for the front axle is 8,800 lb., that of the rear axle being 19,500 lb. The singlespeed axle has a reduction ratio of 5.857 to 1, but Eaton two-speed axles are available as optional equipment at extra cost.

Home market chassis can have the 16802 axle, with ratios of 7.15 and 5.14 to 1, whilst export versions have the heavier 18802 axle, the ratios of which are 7.02 and 5.14 to I. In the case of home-market chassis required for heavy-duty applications, such as the basis for concrete agitators, the 18802 axle could be fitted at the manufacturers' recommendation.

Girling Brakes

Girling two-leading-shoe hydraulic brakes, boosted by a Clayton Dewandre Airpak air-pressure servo, are standard equipment. The servo is the ASR2/400 model, with 4-in.diameter piston and 8.25-in.-diameter reservoir, the size of the reservoir being sufficient to provide 21 full brake applications before the low-pressure warning light is actuated. Power for the servo is derived from a single-cylinder compressor working off one of the engine rocker-arm pins.

The front brakes are 15.25-in. x 4.25-in, assemblies, whilst the rears are 15.5-in. X 6-in. units, the total lining area being 618 sq. in. The single-pull handbrake lever is to the left of the driver (on right-hand drive chassis) and oilimpregnated bushes are used on the cross-shaft and the pins in the relay levers.

Standard tyres are 9.00-20 (12-ply) on B.7.0-20 10-stud 6-in.-off-set wheels. As optional equipment 10.00-20 (12ply) tyres can be specified on the same wheels except when the Commer-built 6-cu.-yd. tipping body is fitted.

Cam Gears' cam-and-peg steering gear with a ratio of 23.5 to 1 is employed. This is fitted with a 20-in.-diameter, T-spoked steering wheel requiring five turns from lock to lock. Theoretical turning circles are 46 ft. in the case of the tipper and 62 ft. for the long-wheelbase chassis.

The well-known Rootes two-stroke three-cylindered diesel engine is the sole engine available in the new 8-ton chassis. This 3.26-litre unit has a net output of 100 b.h.p. at 2,400 r.p.m., the net torque rating being 270 lb.-ft. at 1,200 r.p.m. The engine carries a Borg and Beck 13-in.diameter solid-centre clutch, mechanically operated through a ball-bearing release bearing. There. are no gearbox options, the standard unit being a Commer five-speed constant-mesh box with forward ratios of 7.514, 4.263, 2.374, 1.474 and Ito 1. reverse being 7.814 to 1.

Engine-Gearbox Assembly

The engine-gearbox assembly has a three-point mounting, with a single Metalastik sandwich at the front and two Metacones at the rear on the line of the clutch. Hardy Spicer 1600-series jointed propeller shafts are employed, the tipper chassis having a single shaft. The long-wheelbase version has a two-piece shaft with a rubber-mounted, selfaligning centre bearing.

A capacity of 32.25 pints is given by the engine cooling system, which is pressurized to 4 p.s.i. The radiator has a surface area of 425 sq. in. Home-market chassis have a four-row block, a five-row assembly being available for tropical countries. A 17-in.-diameter, six-bladed fan is fitted. The standard fuel tank has a capacity of 30 gal., and this is mounted on the right-hand side of the chassis frame. The two 6-v. 115-amp.-hr. batteries also are on the right side of the frame on long-wheelbase chassis, but are mounted inside the left-hand side member on the tipper model, the spare wheel of this chassis being immediately below the batteries.

The new 74-tonner, which is offered with a choice of three wheelbases and diesel or petrol engines is, in effect, a combination of the QX 7-tonner and the new CA 8-tonner. On standard tyres the gross weight rating is 11 tons 3 cwt., which is the same as the maximum rating of QX 7-ton models on oversize tyres. The wheelbases offered are 9 ft. 7 in., 11 ft. 9 in., and 13 ft. 6 in. The short-wheelbase model is available with a 6-cu.-yd. tipping body, whilst the other models are suitable for 15-ft. 6-in.-long and 8-ft.-long bodywork respectively.

Similar Chassis Frame Like the 7-tanner, the new 71-tanner has a high-tensilesteel chassis frame with 8.5625-in.-deep, 0.219-in.-thick side members, these having 2.5625-in.-wide top flanges and 3-in.wide bottom flanges. The semi-elliptic springs at front and rear have the same dimensions as those used on the 8-ton chassis, but fewer leaves are employed. Helper springs are offered as optional equipment.

The rear axle also is virtually the same as that of the 8-tanner, except that it has eight-stud hubs, whilst the front axle is a standard 7-ton unit. The standard single-speedaxle ratio on the mediumand long-wheelbase models is 5.125 to I, that on the short-wheelbase chassis being 5.857 to 1, An Eaton 16802 two-speed axle is optional, the ratios being 7.15 and 5.14 to 1.

A Clayton Dewandre Hydrovac vacuum servo has been adopted as standard equipment to boost the Girling twoleading-shoe hydraulic brakes, and an Airpak air-pressure servo is optional. The front brakes on all models are 16-in. X 3-in, units, petrol-engined chassis having 15.25-in. X 5-in. rear brakes and diesel models having 15.5-in. x 6-in. equipment at the rear. These give respective total lining areas of 482 sq. in. and 548 sq. in. respectively.

Alternative Power Unit The diesel engine offered in the 71-tormer is the Rootes diesel with the same ratings • as in the 8-tanner. The alternative power unit is the Commer six-cylindered o.h.v. petrol engine, a 4,75-litre unit with net ratings of 103.5 b.h.p. at 3,000 r.p.m. and 230 lb.-ft, torque at 1,200 r.p.m. The diesel engine has a 13-in.-diameter clutch, the clutch on the petrol engine having a diameter of 12 in.

A four-speed synchromesh gearbox is standard equipment, this having forward ratios of 7.227, 3.478, 1.838 and 1 to 1 (reverse, 8.431 to 1), an overdrive ratio of 0.821 to 1 being available as a production option to convert the box into a five-speed unit. Alternatively, the five-speed constantmesh gearbox used in the 8-tanner may be specified.

All the 7+-ton models have 8.25-20 (14-ply) tyres on B.6.0-20 wheels (5.1-in, off-set) as standard equipment, with the option of 9.00-20 (12-ply) tyres on 8.7.0-20 (6-in. off-set) wheels. The gross weight rating is increased to Ii tons 6 cwt. when the larger tyres are fitted.

Apart from the use of the new cab and the provision of either Hydrovac or Airpak servos, the new 10/11-ton and 12-ton tractive units have the same specifications as the models they supersede, the gross train weight ratings being 16 tons 5 cwt., and 17 tons 10 cwt. respectively (the 12-ton unit may be operated at 18 tons gross when a two-speed axle and fifth-wheel coupling are fitted). When the Airpak servo is fitted provision is made for two-line trailer braking.