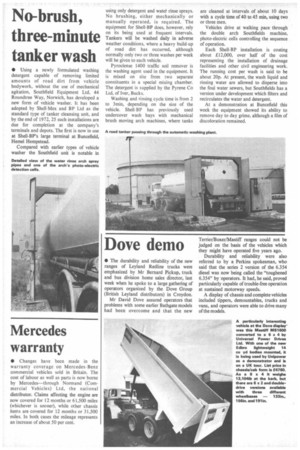

No-brush, three-minute tanker wash

Page 34

If you've noticed an error in this article please click here to report it so we can fix it.

• Using a newly formulated washing detergent capable of removing limited amounts of road dirt from vehicle bodywork, without the use of mechanical agitation, Southfield Equipment Ltd, 44 Roundtree Way, Norwich, has developed a new form of vehicle washer. It has been adopted by Shell-Mex and BP Ltd as the standard type of tanker cleansing unit, and by the end of 1972, 25 such installations are due for completion at the company's terminals and depots. The first is now in use at Shell-BP's large terminal at Buncefield, Hemel Hempstead.

Compared with earlier types of vehicle washer the Southfield unit is notable in

using only detergent and wateirinse sprays. No brushing, either mechanically or manually operated, is required. The equipment for Shell-BP does, however, rely on its being used at frequent intervals. Tankers will be washed daily in adverse weather conditions, where a heavy build-up of road dirt has occurred, although normally only two or three washes per week will be given to each vehicle.

Pyroclense 1400 traffic soil remover is the washing agent used in the equipment. It is mixed on site from two separate constituents in a special mixing chamber. The detergent is supplied by the Pyrene Co Ltd, of Iver, Bucks.

Washing and rinsing cycle time is from 2 to 3min, depending on the size of the vehicle. Shell-BP has previously used undercover wash bays with mechanical brush moving arch machines, where tanks are cleaned at intervals of about 10 days with a cycle time of 40 to 45 min, using two or three men.

Vehicles drive at walking pace through the double arch Southfields machine, photo-electric cells controlling the sequence of operation.

Each Shell-BP installation is costing about £12,000, over half of the cost representing the installation of drainage facilities and other civil engineering work. The running cost per wash is said to be about 20p. At present, the wash liquid and rinsing water are allowed to disperse into the foul water sewers, but Southfields has a version under development which filters and recirculates the water and detergent.

At a demonstration at Btmcefield this week the equipment showed its ability to remove day to day grime, although a film of discoloration remained.