48 Hours from Egg Producer to Retailer

Page 58

Page 65

If you've noticed an error in this article please click here to report it so we can fix it.

by Ashley Taylor, A.M.1.R.T.E.

Scheduled Collectionsand Deliveries by Commer Fleet Operated byLancashirePoultry Farmer Speed Transit from

Hen to Breakfast Table

pOULTRY and dairy production has developed on a large scale on the fringe of the Lancashire industrial area, where there is a ready market for fresh farm produce. The growth of this industry has been encouraged by the -fact that collection and distribution by road transport ensure a minimum of delay between farm and consumer; as little as 48 hours may elapse from the time new-laid eggs are prepared ready to leave the producer's premises until their delivery to retailers.

Reliable and regular service of this nature scores with the Lancashire egg producers and, in the case of Mr. John Coulthurst, of Bamber Bridge, near Preston, the facilities provided are in increasing demand.

Six Vehicles: Three Farms

Mr. Coulthurst, who has five Commer Superpoise vehicles of 3-4-ton capacity and a Commer Express delivery van, owns three farms with a combined acreage of close on 130. He and his family have always produced and marketed their own eggs, but about 25 years ago they set about assisting neighbours with their selling problems, the collections at that time being carried out with a Morris-Commercial 20-cwt. van.

Three vehicles were employed in 1939, but the quantities of eggs packed fell to a low level during the war. For the past four years, however, packing stations have been free to collect from any producer and, since April 1, 1953, distribution too has been a matter for free enterprise. ' During this period the fleet was entirely renewed, and, in addition, Mr. Coulthurst employs an International tractor and a Fordson Major tractor. As well as over 10,000 birds, he also has 100 head of pedigree recorded T.T. Friesian cattle. There is a staff of nearly 40.

The fleet collects from nearly 700 egg producers each week, most of them being located within a 15-mile radius of Bamber Bridge. The eggs are carried to Mr. Coulthurst's packing station in boxes, each of which has a capacity of 30 dozen. There. skilled operators test them for quality and grade them for size. They are then packed in the various grades, modern machinery being employed for each process.

Packing stations are, in effect, t r a din g organizations. Support through a subsidy is given by the Ministry of Food at some seasons, so that egg prices are maintained at controlled levels in the shops even though it may be necessary to pay higher figures to the producer.

Detailed Records

Because of the subsidy, accurate records must be kept of all eggs received and sold, and the machinery, which automatically counts the eggs and gives the numbers of the different grades, is of great assistance.

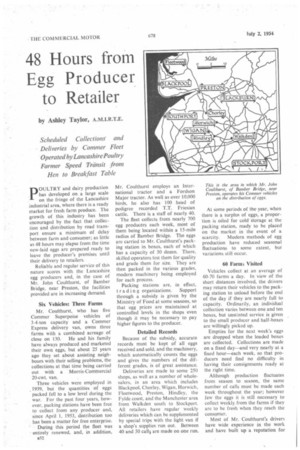

Deliveries are made to some 250 shops, as well as a number of wholesalers, in an area which includes Blackpool, Charley, Wigan, Harwich, Fleetwood, Preston, Hindley, the Fylde coast, and the Manchester area from Walkden south to Stockport. All retailers have regular weekly deliveries which can be supplemented by special trips with the light -van if a shop's supplies run out. Between 40 and 50 calls are made on one run. At some periods of the year, when there is a surplus of eggs, a proportion is oiled for cold storage at the packing station, ready to be placed on the market in the event of a scarcity. Modern methods of egg production have reduced seasonal fluctuations to some extent, but variations still occur.

60 Farm; Visited

Vehicles collect at an average of 60-70 farms a day. In view of the short distances involved, the drivers may return their vehicles to the packing station to unload before the end of the day if they are nearly full to capacity. Ordinarily, an individual collection varies between one and ten boxes, but unstinted service is given to the small producer and half-boxes are willingly picked up.

Empties for the next week's eggs are dropped when the loaded boxes are collected. Collections are made on a fixed day—and very nearly at a fixed hour—each week, so that producers need find no difficulty in having their consignments ready at the right time.

Although production fluctuates from season to season, the same number of calls must be made each week throughout the year; however few the eggs it is still necessary to collect weekly, from the farms if they are to be fresh when they reach the consumer.

Most of Mr. Coulthurst's drivers have wide experience in the work and have built up a reputation for friendly co-operation with their customers. Each normally has his own round so that he knows the habits of the various farms. In order to broaden their experience, however, the driving staff undertake each other's rounds from time to time. In an emergency, other workers act as reserve drivers.

When the eggs are brought in to the packing station the boxes are off-loaded on to stillages and delivered to the grading room as required. Each box contains the producer's name so that when the eggs are tested a report of the contents can be prepared and slips made out in readiness for payment.

The report for each individual is passed to the office, where a further check is made by means of mechan

ized accounting equipment to ensure that each producer is paid in accordance with the exact number of eggs sent in. A pay slip showing how the eggs have been graded is then prepared for payment, a copy of each grading statement being filed for 'uture reference. By means of this iling system, an important service an be given to a producer, as a ;ertificate for accountancy purposes an be issued showing the amount mid for any specified period.

The loading deck from which eggs ire consigned is connected directly vith the grading room. Egg cases 'rom the graders are put on to stillages and moved by Collis trucks to the dispatch warehouse. Here the concrete deck is at platform level, and all loading and unloading takes place under cover.

Graded eggs are packed ready for dispatch in 30-dozen boxes, being laid in Keys egg trays, in which they are quite safe for normal transport handling. Boxes are packed four high, the total capacity of each vehicle being 144.

The bodywork on the vehicles consists of a built-up front and back and a fixed top. There are sliding side curtains so that the load is easily accessible and yet protected from the weather. Although the platform has no chock rail, the outer boards are shaped in such a way that the outside box leans slightly inward, so giving

stability to the load. The roof is high enough for a man to stand on the platform beneath and to work under cover.

In round figures the vehicles run an average of 20.000 miles each a year, and an inspection suggests that they are carefully maintained by their individual drivers, who devote Saturday mornings to cleaning, greasing and routine adjustments. Defects are reported by the drivers to Mr. Coulthurst, and the vehicles are sent to a local garage.

Mileages of up to 70,000 have been recorded by the Commers before

fitting reconditioned engines. The Commer full-length chrome-bored unit is employed on the latest models.