Research Aids Efficiency in CI Engines on Producer Gas

Page 25

If you've noticed an error in this article please click here to report it so we can fix it.

A S mentioned from time to time in

this journal, the Institution of Automobile Engineers, in conjunction with the M.O.W.T. Directorate of Alternate Motor Fuels and in collaboration with C.A.V., Ltd., and the Zenith C_arburetter Co., Ltd., has been conductingexperiments at its research laboratories in connection with the running of oil engines on producer gas, whilst retaining fuel injection for ignition purposes.

Previous I.A.E. Bulletins have dealt fully with injection timing, quantities of liquid fuel required to cause ignition, and proportioning the gas and air mixture, with particular reference to the I.A.E. mixing valve.

In all these tests, however, there was according to the Bulletin, a certain degree of artificiality as the pump controls were operated independently, of the gas control. Subsequient experiments, therefore, have been directed mainly towards securing satisfactory control of the fuel pump for the small injection quantities required, whilst, at the same time, retaining the standard pump elements.

Initial experiments led to the conclusion that the minimum quantity of fuel to promote ignition rose with engine speed, but subsequent tests have shown that this is not so, and that it is possible to obtain regular firing with a constant fuel quantity at speeds above 800 r.p.m. It was found that throughout a speed range from 800 r.p.m.

to 1,800 an average fuel-injection quantity of between 9 and 10 cubic mm. per cycle is sufficient to give satisfactory ignition of the mixture.

A reasonable approximation to the running-fuel requirement through a limited speed range is obtained with a fixed rack setting, the rack position being set to give minimum injection for regular firing at 900 r.p.m. Such a setting, however, resulted in ignition failure at speeds much below 900 r.p.m., owing to the rapid fall in fuel injection with reduced speed.

With the fixed rack-stop position giving minimum injection at 900 r.p.m., a reduction in injection pressure, from 175 to 120 atmospheres, reduced the critical speed at which ignition failure occurred to about 950 r.p.m. The fuel quantities injected were slightly increased at the highest speeds, and varied linearly With speed. There was little reduction in engine torque below 1,000 r.p.m., but the engine would run for only about five minutes at the minimum speed before ignition failure occurred.

A C.A.V. pump, modified in respect of the eccentric shaft, levers and governor, is being adopted for the first service trials.

Regarding the I.A.E. mixing valve, we are now able to give details of the production version which, we understand, has given results as satisfactory

as the experimental model to which reference was made in our issue dated April 2.

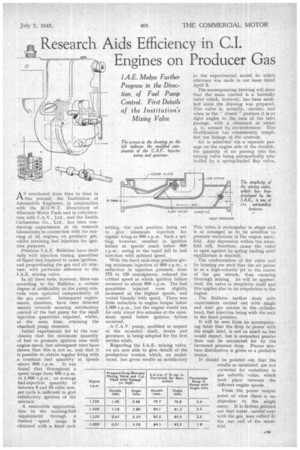

The accompanying drawing will show that the main control is a butterfly valve which, however, has been modified since the drawing was prepared. This valve is, actually, circular, and when in the " closed " position it is at right angles to the axis of the inlet passage, with a clearance of about in. around its circumference. This modification has considerably simplified the linkage of the controls.

Air is admitted via, a separate passage on the engine side of the throttle. the quantity of air passing into the mixing valve being automatically ccintrolled by a' spring-loaded flap valve.

This valve is rectangular in shape and is so arranged as to be sensitive to pressure variations in 'the engine manifold. Any depression within the manifold will, therefore, cause the valve to open against its spring loading until equilibrium is reached.

The conformation of the valve and its housing are such that the air passes in as a high-velocity jet to the centre of the gas stream, thus ensuring thorough mixing. As will be appreciated, the valve is simplicity itself and this applies also to its adaptation to the engine.

. The Bulletin further deals With experiments carried out with single and dual gas entries in the cylinder head, fuel injection being with the rack in the fixed position.

It will be seen from an accompanying table that the drop in power with the single inlet, is not as much as one would expect, but is somewhat greater . than can be accounted for by the — increased pressure drop. Poorer mixture distribution is given as a probable reason, It should be pointed out that the results as tabulated, are not corrected for variations in gas calorific value, which took place between the different engine speeds.

From 'the power output point of view there-is .no objection to the single entry. • It is further pointed out that water, carried over with the gas, may collect at the rear end of the manifold.