THE AKRA MOTOR-PLOUGH.

Page 2

If you've noticed an error in this article please click here to report it so we can fix it.

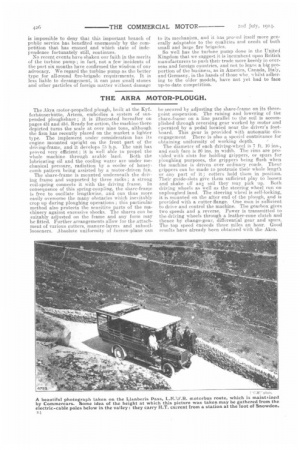

The Akra motor-propelled plough, built at the Kyf. ferhauserhate, Artern, embcdies a system of suspended ploughshare.; it is illustrated hereafter on pages 431 and 454. Ready for action, the machine there depicted turns the scale at over nine tons, although the firm has recently placed on the market a lighter type. The implement under consideration has its engine mounted upright. on the front part of the driving-frame, and it develops 75 h.p. The unit has proved very efficient ; it is well able to propel the whole machine through arable land. Both the lubricating oil and the cooling water are under mechanical pressure, radiation by a cooler of honeycomb pattern being assisted by a motor-driven fan.

The share-frame is mounted underneath the driving frame and supported by three racks ; a strong coil-spring connects it with the driving frame. In consequence of this spring-coupling, the share-frame is free to oscillate lengthwise, and can thus more easily overcome the many obstacles which inevitably crop up during ploughing operations ; this particular method also protects the sensitive parts of the machinery against excessive shocks. The shares can he suitably adjusted on the frame and any form may be fitted. Further arrangements allow for the attachment of various cutters, manure-layers and subsoillooseners. Absolute uniformity of furrow-plane can be secured by adjusting the share-frame on its threepoint suspension. The raising and lowering of the share-frame on a line parallel to the soil is accomplished through reversing gear worked by motor and eperated by a pedal located near the driver's foot. board. This gear is provided with automatic disengagement There is also a special contrivance for obtaining uniformity of working depth. The diameter of each driving-wheel is 7 ft. 10 ins., and each face is 20 ins, in width. The rims are proWed with slots for holding grippers, or spurs for ploughing purposes, the grippers being flush when the machine is driven over ordinary roads. These grippers can be made to protrude their whole length or any part of it ; cotters hold them in position. Their guide-slots give them sufficient play to loosen and shake off any soil they may pick up. Both driving wheels as well as the steering wheel run on unploughed land. The steering wheel is self-locking, it is mounted on the after end of the plough, and is provided with a cutter-flange. One man is sufficient to drive and control the machine. The gearbox gives two speeds and a reverse. Power is transmitted to the driving wheels through a leather-cone clutch and thence by change-gear, differential gear and spurs. The top speed exceeds three miles an hour. Good results have already been obtained with the Akra.