HINTS ON MAINTENANCE.

Page 28

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

How to Get the Best Out of a Vehicle, to Secure Reliability and to Avoid Trouble.

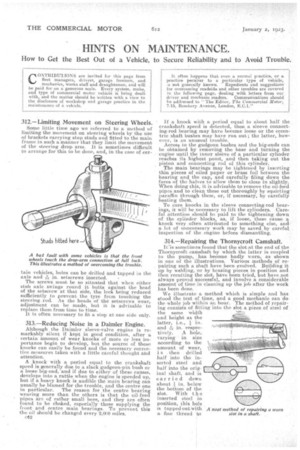

312.— Limiting Movement on Steering Wheels.

Some little time ago we referred to a method of limiting the movement, on steering wheels by the use of brackets carrying stop studs and fitted to the main frame in such a manner that they limit the movement of the steering drop arm. It is sometimes difficult to arrange for this to be done, and, in the case of cer

fain vehicles, holes can be drilled and tapped in the axle and A in. setscrews inserted.

The screws must be so situated that when either stub axle swings round it butts against the head of the setscrew at that side, the lock being reduced sufficiently to prevent the tyre from touching the steering. rod. As the heads of the setscrews wear, adjustment can be made, but it is advisable to replace them from time to time.

It is often necessary to fit a stop at one side only.

313.—Reducing Noise in a Daimler Engine.

Although the Daimler sleeve-valve engine is remarkably silent if kept in good condition, after a certain amount of wear knocks of more or less importance begin to develop, but the source of these knocks can easily be found and the necessary corrective measures taken with a little careful thought and attention.

A knock with a period equal to the crankshaft speed is generally due to a slack gudgeon-pin bush or a loose big-end,'and if due to either of these causes, develops into a rattle when the engine is speeded up, but if a. heavy knock is audible the main bearing can usually be blamed for the trouble, and the centre one

in particular. The reason for the centre bearing wearing more than the others is that the oil-feed pipes are of rather small bore, and they are often found to be choked, especially those supplying the front and centre main bearings. To prevent this the oil should be changed eVery 2,oco miles.

012

If a knock with a period equal to about half the crankshaft speed is detected, then a sleeve connecting-rod bearing may have become loose or the eccentric shaft bushes may have run out ; the latter, however, is an unusual trouble. Access to the gudgeon bushes and the big-ends can be obtained by removing the base and turning the engine until the inner sleieve of a particular cylinder reaches its highest .point, and then taking out the piston and connecting rod of this cylinder. The main bearings may be tightened by inserting thin pieces of oiled paper or brass foil between the bearing and the cap, and carefully filing down the faces of the halves to allow them to close in slightly. When doing this, it is advisable to remove the oil-feed pipes and to clean -these out thoroughly by squirting paraffin through them, or, if necessary, by carefully heating them.

To cure knocks in the sleeve connecting-rod bearings, it will be necessary to lift the cylinders. Careful attention should be paid to the tightening down of the cylinder blocks, as, if loose, these cause a knock very .often attributed to something else, and a lot of unnecessary work may be saved by careful. inspection of the engine before dismantling.

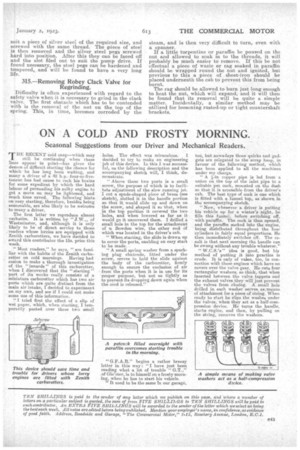

314.—Repairing the Thornycroft Camshaft.

Wis sometimes found that the slot-at the end of the Thornycroft camshaft by which the latter is coupled to the pump, has become badly v;orn, as shown in one of the illustrations. Various methods of repairing such a shaft have been evolved. Building it up by welding, or by brazing pieces in position and then reeutting the slot, have been tried, but have not always proved successful, and involve a considerable amount of time in cleaning up the job after the work has been done.

We illustrate a method which is simple and has stood the test of time, and a good mechanic can do the whole job within an hour. The method of repairing consists of fitting into the slot a piece of Steel of the same width and height as the latter, i.e.,

and A in. respec tively. A hole, varying in size according to the amount of wear, i then drilled half into the inserted steel and half into the original shaft, and is car ried down about in. below the bottom of the slot. With the inserted steel in position, this hole is tapped out With a Ane thread to

suit a piece of silver steel of the required size, and screwed with the .same thread. The piece of steel is then removed and the silver steel pegs screwed hard into position. After this they can be faced off and the slot filed out to suit the pump drive. If found necessary, the steel pegs can be hardened and tempered, and will be found to have a very long life.

315.—Removing Robey Clack Valve for Regrinding.

Difficulty is often experienced with regard to the safety valve when it is necessary to grind in the clack valve. The first obstacle which has to be contended with is the removal of the nut on the top of the spring. This, in time, becomes corroded by the steam, and is then very difficult to turn, even with a spanner. If a little turpentine or paraffin be poured on the nut and allowed to soak in to the threads, it will probably be much easier to remove. If this be not effectual a piece of waste or rag soaked in paraffin should be wrapped round the nut and ignited, but previous to this a piece of sheet-iron should be placed underneath the cab to prevent this from being burnt.

The rag should be allowed to burn just long enough to heat the nut, whiih will expand, and it will then be found that its removal will be quite a simple matter. Incidentally, a similar method may be utilized for loosening rusted-up or tight countershaft brackets.