For DRIVERS MECHANICS & FOREMEN.

Page 21

If you've noticed an error in this article please click here to report it so we can fix it.

A PRIZE OF' TEN SHILLINGS is aicarded each week to the render of the best letter which we publish on this page ; all others are paid for at the rate of a penny a line, with an allowance for photographs. All notes are edited before being

published. Mention your employer's name, in confidence, as evidence of good faith, Address, M. and F., "The .Oommercial Motor," 7-145, Rosebery Avenue, London, E.G. 1.

Lamps Alight.

On Saturday, 4th January, light your lamps at 4.31 in London, 4.47 in Edinburgh, 4,17 in Newcastle, 4.32 in Liverpool, 4.33 in Birmingham, 4.41 in Bristol, and 5.17 in Dublin.

Another Use for a Syrup Tin.

The sender of the following communication has been awarded the 10s. prize this week.

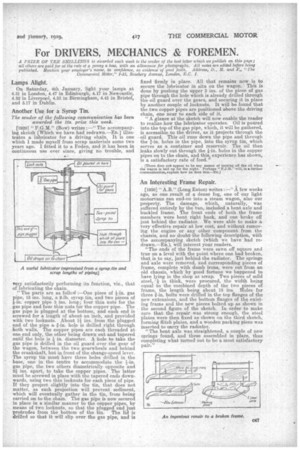

[1929]" F.G.M." (Bow) writes :—" The accompanying sketch [Which we have had redravirn.—En.1 illustrates a lubricator for a driving chain. It is one which I made myself from scrap materials some two years ago. I fitted it to a Foden, and it has been in continuous use ever since, giving no trouble, and

very satisfactorily performing its function, viz., that of lubricating the chain. "The parts are as folio* :---One piece of i-in. gas pipe, 15 ins, long, a 2-1b. syrup tin, and two pieces of

copper pipe 3 ins. long.; four thin nuts for the gas pipe and four thin nuts for the copper pipe. The gas pipe is plugged at the bottom, and each end is screwed for a length of about an inch, and provided with two locknuts. About 1i ins, from the plugged end of the pipe a f-in. hole is drilled right through both walls. The copper pipes are each threaded at one end only, the other being drawn out and tapered until the hole is in. diameter. A hole to take the gas pipe is drilled in the oil guard over the gear of the wagon, between the two gearwheels and behind the crankshaft, but in front of the change-speed lever. The syrup tin must have three holes drilled in the base, one in the centre to accommodate the

gas pipe, the two others diametrically opposite and 2-i ins, apart, to take the copper pipes. The latter must he screwed in place with the tapered ends downwards, using two thin locknuts for each piece of pipe. If they project slightly into the tin, that does not matter, as such projection will prevent sediment, which will eventually gather in the tin, from being carried on to the chain. The gas pipe is now secured in place in a similar manner to the copper pipes, by means of two locknuts, so that the plugged end just protrudes from the bottom of the tin. The lid is drilled so that it will slip over the gas pipe, and is

fixed firmly in place. All that remains now is to secure the lubricator in situ on the wagon. This is done by pushing the upper 3 ins, of the piece of gas pipe through the 'hole which is already drilled through the oil guard over the gears, and securing it in place by .another couple of locknuts. It will be found that the two copper pipes are positioned above the driving chain, one near to ,each side of it. " A glance at the sketch will now enable the reader to realize how the lubricator operates. Oil is poured into the top of the gas pipe, which, it will be gathered, is accessible to the driver, as it projects through the oil guard. This oil runs clown the pipe and through the g-in. holes in the pipe, into the syrup tin, which serves as a container and reservoir. The oil then leaks slowly out through the i-in. holes in the copper pipes on. to the chain, and this, experience has shown, is a satisfactory rate of feed."

[There does not appear to be any means of turning off the oil when the wagon is laid up for the night. Perhaps " P.J.M." will, in a farther communization, explain how he does this.—En.]

An Interesting Frame Repair.

[1930] " A.B." (Long Eaton) writes :—" A few weeks ago as one result of a dense fog, one of our light maorvans ran end-on into a steam wagon, also our property. The damage, which, naturally, was suffered entirely by the Van, included a bent axle and buckled frame. The front ends of both the frame members were bent right back, and one broke off just behind the radiator. We were able to make a very effective repair at low cost, and without removing the engine or any other component from the chassis, and no doubt.the following description, with the accompanying sketch (which we have had redrawn.—En.), will interest your readers. 'The ends of the frame were sawn off square and true on a level with the point where one had broken, that. is to say, just behind the radiator. The springs and axle were removed, and corresponding pieces of frame, complete with dumb irons, were cut from an old chassis, which by good fortune we happened to

i

have lying n the shop as scrap. Two pieces of mild steel, ‘i in thick, were procured, the width being equal to the combined depth of the two pieces of frame, the length being about 15 ins. Holes for three f-in. bolts were drilled in the top flanges of the new extensions, and the bottom flanges of the existing frame and the new pieces bolted up as shown in the second figure of the sketch. In order to make sure that the repair was strong enough, the steel plates were then fixed as shown on the third sketch, forming flitch plates, and a wooden packing piece was inserted to wry the radiator.

"The bent axle was straightened, a couple of new springs found, and these assembled in place, thus completing what turned out to be a, most satisfactory pain