THE REPAIR OF COMMERCIAL VEHICLES.

Page 10

Page 11

If you've noticed an error in this article please click here to report it so we can fix it.

How. the Agent and Repairer Should Equip His Depot and Repair Works. ,

N VIEW OF the urgent need at the present re I construction period for properly-constructedkand efficiently-managed repair depots, the following remarks may not seem out of place, and perhaps will be a source of help and inspiration to those who contemplate carrying out repairs on a larg.e scale.

The motor vehicles, whether car or lorry, which are returned from service abroad, will be expected, after renovation and repair, to be almost equal to new by the majority of their future owners. Therefore, it_ behoves the manufacturers of these vehicles to see that their agents or commissioned repairers are fully' equipped with modern facilities to carry out all necessary repair to the vehicles, thereby ensuring at least that their own reputation as makers of first-class vehicles shall still be up to their claims. Moreover, with the provision of a trained engineer, who thoroughly understands the internal economy of a chassis, and who is up to date in methods of finish, treatment of metals, and of vehicle design in all its phases, the makers will be adding to their future prosperity by proving the wearing qualities of chassis bearing their name.

Keep Cars. and Commercial Vehicles Amt.

In the first place, the repair of commercial vehicles and of pleasure cars must be carried out inwentirely separate dePartments, and by a distinctly different class of mechanics.

Further, if the two repair sections (using the term section in place of department) are under the general _management of one head, there should, of necessity, be an engineer manager specially i

qualified for the work n each section and directly responsible for the carrying out of all overhauls and repairs in his own particular section. Anyone with a technical knowledge of the two classes of vehicles will readily understand tht reason for this. The result amounts to this—that the two sections can only be successfully dealt with as two separate establishments, even preferably situated under separate roofs. The best position of a pleasure car repair shop and garage is near the centre of a popular part of a town, whereas that of a commercial vehicle depot

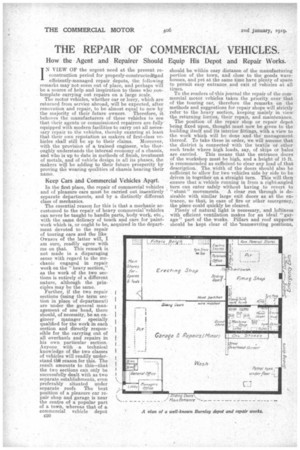

should be within easy distance of the manufacturing portion of the town, and close to the goods ware houses, arid yet at the same time have plenty of space to permit easy entrance and exit of vehicles at all times.

To the readers of this journal the repair of the commercial motor vehicles takes the priority over that of the touring ear, therefore the remarks on the methods and suggestions for repair shops will strictly refer to the heavy section, keeping mainly in view the returning lorries, their repair, and maintenance.. The position of the repair shop or repair depot being fixed upon, thought must now be given to the building itself and itS interior fittings, with a view to the work which will be done andthe• management thereof. To take these in order, we will assume that the district is connected with the textile or other such trade where high loads, say, of skips or bales are carried. This means that the entrance doors

of the workshop must be high, and a height of 15 ft.

is recommended as sufficient to clear any load of that description. The width of the doors should also be sufficient to allow for two vehicles side by side to be driven in together on a straight turn. This will then ensure that a vehicle running in from a right-angled turn can enter safely without having to revert to "stunt" movements. A clear run through is desirable with similar large exit doors as at the entrance, so that, in case of fire or other emergency, the place could quickly be cleared.

'Plenty of natural light is necessary, and loftiness with efficient ventilation makes for an ideal "garage" part of the works. Pillars and roof supports should be kept clear of the -manceuvring positions, and, if possible, set back into the walls, thereby giving all the available floor space to the "parking" of the vehicles, and also preventing collisions. Where a travelling crane is erected—and this is a valuable asset both for lifting off the complete load and body from the chassis, and for getting a quick reversal of the chassis by hitching up to one end and swinging the chassis round in its own radius—it is better to fix the standards or supports to one side of the main shop.

It might here be mentioned that, with regard to the dimensions of the repair works, whilst everything depends on the ground available, the garage portion should not be less than, say, 100 ft. square, or its equivalent. One particular works having a larger garage space than this has often been found to be cramped for room when busy, although the place looked very roomy when slack days came along, which were not very often. A building of this description is the one which is in mind in the present article.

The Need for Modern Machine Tools.

The machine shop, which must be built in close juxtaposition with the main shop or garage, should be replete with modern tools to deal successfully with the varied classes of work which repairers are called upon to do, such as the turning and boring of bushes, turning and screwing of shafts and pins, grinding of pins, bushes, cylinders -and pistons, etc., making of valves, boring, facing and milling of crankcases, gearboxes and rear axle details, gear-cutting, splining, etc.

It is, therefore, obvious that antiquated machinery is of little use, and I suggest, as a minimum, the installation of the following machines.

A 9k-in, centre engine lathe with large and small face plates, and having a gap bed giving a 30-in. swing. This is a heavy-duty machine, and is utilized for the heaviest work up to road wheels. A 9k-in. all-geared hollow-spindle (21-in.) lathe, turret tool post, and with taper turning attachment..

Two 6k-centre hollow-spindle lathes, screw-cutting surfacing, sliding, etc., taper, turning attachments and micrometer adjustments. Pins and bushes will keep these two machines busy.

All lathes should be of the screw-cutting type.

Two very essential machines required are a universal milling machine with all attachments, and a universal grinder. There are so many parts for the repair works to make which come into the category of these two machines that the workshop is not complete without them.

A radial drilling machine to drill up to 21 ins, is also a necessary tool.

Two other vertical drilling machines up to drill, and a sensitive drill, up to will also be required.

A couple of portable drills, electric or compressedair type, for chassis drilling. The former should have at least 50 ft. of cable, with plug and switch to couple up to convenient wall plugs, so as to be able to carry out any drilling work up to 1-in, diameter in any part of the works.

The usual tool-grinding machines and power hacksaw, etc., of course, should be installed. In the smithy the open hearth with deep well and drop-sided smith's fire, with an adequate air blast, is required. This must be large enough to take work of varietyasuch as frame side members, front axles, etc., and the like.

One of the most important departments of the repair shop is that of welding. This plant, preferably of the oxy-acetylene type, should also be portable, and, of course, must be in the hands of a man thoroughly skilled in the art of welding all classes of metal. The first cost of a welding plant will repay itself in a very short time ; so many repairs can be made good in a fraction of the time as compared with what could be done previously by old-fashioned methods, and, moreover, with neatness and finish. To get along without a welding outfit is like trying to run a present-day,business with horsed transport ; it can be done evenTually, but it is decidedly slow.

Heat Treatment Facilities.

Further and equally important additions to the repair work are the annealing and hardening furnaces, fitted with a guaranteed pyrometer. In the repair of all types of motor vehicles a variety of steels is used, varying in carbon contents and other chemical properties, and, with each, a different heat treatment is required, according to the purpose for which the part is required, and the maintenance of their physical qualities depends on the correct procedure. It is, therefore, essential that the management should have a full knowledge of metallurgy, heat treatment, and hardening methods, in order to gain the full advantage in the choice of steels to give the best results.

A brazing hearth with a good blast,-and also a small. bearing metal furnace, .together with suitable moulds, would complete an ideal workshop, so far as regards the machining side. In the main shop or garage portion a dozen large special dhassis jacks are needful. They should be so designed as to take the load directly through ball thrust bearings. Time is money, and anything in the way of easing effort and cutting down of the time to be spent on any job is to be aimed at. Where an overhead travelling crane cannot be conveniently erected, portable floor cranes, having a height sufficient to raise an engine clear of the frame top, should be supplied, with the base sufficiently wide to span the front wheels clear of the tyres. The majority of cranes sold at present do not do this.

Magneto and carburetter repairs should be carried out in a special department where cleanliness is strictly enforced. Components each should have a definite position in the shop, with a special set of mechanics for each, so far as is possible, so as to save time in diagnosing faults by making each man an expert in his particular branch. The stores for the spares and the machine shop tool stores should also be separate, the latter to be built up to the machine shop. This is a boon. It is a saver of time, and it helps the spares department to carry out their work without confusion.

An indepeadent tester should be kept, and, as each wagon is finished, it should be passed over to this man for final unbiased test, and he should, therefore, be responsible to the departmental manager for his report. As will be seen, the proper repair of commercial . vehicles is not of the "white dust-coat mechanic's" job, but weal engineering business, which calls for the highest skill, quickness of judgment, and the capacity for carrying out the work satisfactorily in every department. A workable system, must be kept up, and shifts must be arranged so as to avoid overtime and week-end work, although, on special occasions, this may have to be done. Overtime and weekend working, once commenced, however, it is difficult to put a Stop to them, 'and efficient work can never be expected •nor+ done out of normal hours: Human beings differ so much from machines.

H. DRAPEB,