TANKER OR TIPPEE FOR ANIMAL FEED'

Page 62

Page 63

Page 64

If you've noticed an error in this article please click here to report it so we can fix it.

by Paul Brockington

IS A RELATIVELY high loading height the most common practical disadvantage of the pressuredischarge animal feed bulk tanker, apart from cost, if it is compared with the conventional open-top tipping vehicle with rotary seal discharge? The difference in loading height is about lft 6in. to 2ft and this can be the decisive disadvantage of the tanker if a height of less than about 12ft is required.

How often could it be a decisive disadvantage? No one can answer that question, relative to the entire country. But no one suggests that the open-top tipper is on the way out. It's a must for any operator who carries bagged materials from time to time or Out of season (unless perhaps he operates a Carmichael demountable tanker) and the low-maintenance advantage of the tanker that is cited by the makers and some operators is disputed by makers who produce only the tipping type, and also by a number of users.

There is little variety in the basic design of different makes of tanker. The tank is pressurized by a standard type of blower and the material of each compartment is aerated in the hopper or by a probe, while the material is discharged by feeding it into a separately controlled stream of air on the outlet side ot the hoppers.

In contrast to the design of tankers, the designs of tipping vehicles vary widely in detail, notably with regard to the rotary seal and ancillary equipment; and the majority of manufacturers are highly critical of other makes. Typically they say that the claims made for the superiority of the tanker may be justified if it is compared with types of tipping vehicle equipment other than their own!

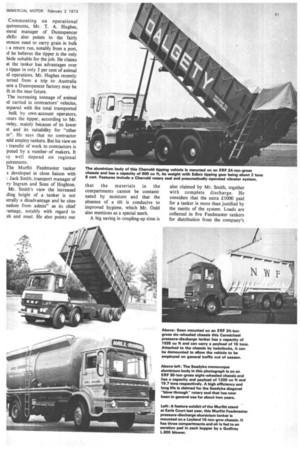

A Feedmaster 720 cu ft non-tipping pressure tanker, based on a 16-ton-gross chassis, was a feature exhibit of the Murfitt stand at Earls Court last year, and Mr. G. Freund, chief engineer and export manager of the company, told CM that operators were going over to tankers in a big way, other than those who had to carry sacks on return runs.

The first animal feed pressure tanker to be based on a rigid chassis by the Carmichael company was completed a short while ago for North Western Farmers; it is a 24-ton-gross six-wheeled vehicle with a 1034 cu ft tank which has a loading height of 12ft 3M. and is demountable from the chassis.

Lower maintenance costs

Both Mr Freund and Mr. W. Ould, assistant technical manager of Carmichael, put reduced maintenance at the top of the list of tanker advantages, followed by speed of discharge, discharge of the material from the hoppers in any order, improved hygiene and higher payload. Mr. Freund states that ti saving on maintenance provided t the Feedmaster is 40 per ceg compared with the company's 5( Series tipping vehicle.

Hubert Leet, managing director Seadyke, claims an indefinite life ft the company's rotary seal, which fed with air diagonally across ti blades. And Robin Rowley, managir director of Pengco claims seven /eight year life for Pengco sea (if the system is handled proper13 All-welded monocoque aluminiu bodies are produced by boi companies.

The necessity to load throul hatches "makes it difficult if n impossible" to bacldoad a tanker wi grain from farms, according to /4,4 Leet and this is regarded as one of tl two major disadvantages of the ty — possibly as serious in genet practice as a low loading height. tribute to the tanker Mr. Leet sa that it comes into its own wh, multiple unit loads of material of sg 1 ton are delivered over shc distances, which is common on t Continent, but is rarely necessary the UK. Partitions are an integi part of a tanker and because relatively large number of compa ments can readily be built into t structure a multi-compartment ty affords an appreciable saving weight.

Backloading is important

Reciprocal trading between farrr and compounder is noted by t Charrold company as an import factor that favours the tipper. And is emphasized that the great distances being covered by in vehicles increase the importance employing a vehicle that can read be backloaded with any type of lot Pig and poultry feeds are in the mg now being carried in low-density fo and this has increased the popular of the 24-ton gvw high-capac six-wheeler. In the case of 30-ton-gross tipper, however, 1 necessity to increase the height of 1 relatively short body could milit against its use as an animal-fl vehicle because of its high centre gravity and loading height. operator quoted by Charrold clai that the tipper is "slightly better ti the tanker" when handling mated with a large particle size, 1 comparable when the material is lit or a meal. Commenting on operational quirements, Mr. T. A. Hughes, :neral manager of Dunnspencer ilk& also points to the fairly pmmon need to carry grain in bulk I a return run, notably from a port, id he believes the tipper is the only hide suitable for the job. He claims at the tanker has advantages over e tipper in only 5 per cent of animal operations. Mr. Hughes recently :urned from a trip to Australia tere a Dunnspencer factory may be ilt in the near future.

The increasing tonnage of animal !,c1 carried in contractors' vehicles, mpared with the total transported bulk by own-account operators, rours the tipper, according to Mr. iwley, mainly because of its lower St and its suitability for "other es". He says that no contractor add employ tankers. But his view on transfer of work to contractors is .puted by a number-of makers. It ty well depend on regional iuirements.

The Murfitt Feedmaster tanker s developed in close liaison with '. Jack Smith, transport manager of Ty Ingram and Sons of Hoghton. Mr. Smith's view the increased ding height of a tanker is not terally a disadvantage and he cites eedom from admix" as its chief tantage, notably with regard to sh and meal. He also points out that the materials in the compartments cannot be contaminated by moisture and that the absence of a tilt is conducive to improved hygiene, which Mr. OuId also mentions as a special merit.

A big saving in coupling-up time is also claimed by Mr. Smith, together with complete discharge. He considers that the extra £1000 paid for a tanker is more than justified by the merits of the system. Loads are collected in five Feedmaster tankers for distribution from the company's mill and also from silos in Liverpool and Birkenhead.

Peet,liar mixes Two conventional tipper /rotary seal vehicles are employed by the company for carrying "peculiar mixes" such as barley and a compound. The payload in this case is less than the rated load because the material is bulky and if the compound is loaded on top of the barley the correct mix is obtained when the vehicle is tipped. For collection of grain from farms it is normally necessary to use a tipper if the vehicle cannot be loaded with a 16ft auger.

As has been mentioned in earlier CM articles on bulk animal feed vehicles, unsatisfactory siting and design of silos are common faults that hinder access to the discharge area, increase unloading time unnecessarily and promote degradation of the material. Difficult access typically favours the use of rigid vehicles (in some cases four-wheelers) and eliminates the artic as a practical proposition.

The tanker might benefit to a considerable extent by more realistic co-operation of farmers with compounders and hauliers and by a larger expenditure on capital equipment all round. Whatever the work-out in future practice, however, it will be a long time before many of the problems of diversity will be solved. And diversity favours the tipper.