A W.D. MODEL. IN ACTIVE PRODUCTION.

Page 9

Page 10

If you've noticed an error in this article please click here to report it so we can fix it.

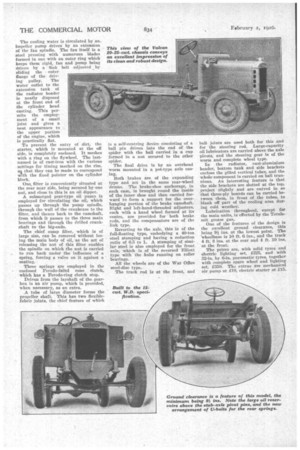

Built Throughout to the War Department's 15-cwt. Specification, the V.M.T. Type Vulcan is Designed to Carry Net Loads of 20-25 cwt.

VIM INTEREST in a new pro111.duet of the Vulcan Motor and Engineering Co. (1906), Ltd., of Crossens, Southport, was aroused at the recent Commercial Vehicle Exhibition. It was, however, not shown in chassis form and, consequently, no detailed examination . of the chassis could be made, and as the vehicle is now being put through the Vulcan works in considerable numbers, it will be of interest to deal with its leading characteristics.

To begin with, the chassis is designed throughout to meet the requirements of W.D. Specification No. 14, dated January, 1925, for a 15-cwt. model. This must not be confused with the specification for the subsidy model, but concerns what the transport experts of the War Department consider an ideal type of chassis for their lighter transport needs, particularly for high-speed vans.

As a civilian vehicle, the new chassis equipped, as it can be, with either solid or pneumatic tyres, and being of simple and robust construction throughout, should be eminently suitable, and is recommended for net loads of from 20 cwt. to 25 cwt. With 32-in. by 6-in. pneumatic tyres it should make an excellent high-speed delivery van, 16-18seater coach, or small bus. The maintenance costs should not be high, as the units are free from complication, and ease of dismantling has received mature consideration.

The frame is perfectly straight in both planes. It has four ,channel-steel cross-members riveted to the side-members, that at the front being dropped to carry the trunnion bearing for the front of the three-pointsuspended power unit. '4Voodhead springs of the semi-elliptic type are employed throughout, and in their securing to the rear axle a considerable improvement has been effected, for the Ti bolts .do not pass through holes in the pads as formerly, but are carried around the pads in semi7 circular grooves. The L. bolts do not pass across the springs, but are joined by bridges. In the (old pattern, the bolts passed through holes in the pad and were liable to rust up.

Pressed steel is employed for the scuttle dash, which is stayed to the frame by light channel pressings and flat gussets.

The steering column, in turn, is stayed to the dash by a V bracket.

Unit construction is employed for the engine and gearbox, and to avoid any risk of binding through frame distortion, the change-speed lever, with its gate, is carried on an aluminium casting forming an extension of the gearbox lid. The hand-brake quadrant, however, is attached to the frame sidemember.

The -four cylinders form i monobloc casting, and have a bore and stroke of 80 mm. and 130 ram. respectively, giving a capacity of 2,614 c.c. and an R.C. rating of 15.9.. The actual. power developed is 18 b.h.p. at 1,000 r.p.m. and 25 b.h.p. at 1,400 r.p.m. The head is detachable in one piece, and is provided with a lug at each corner for

lifting purposes. The cylinders are secured to the • crankcase by the main bearing bolts, which extend right through the ease.

Side valves are employed, these being of three per cent, nickel steel and operated by roller tappets working in

oil mist from the crankcase. To ensure quiet running, the camshaft is of sada a size that it will not whip. It is of C.N.Y. steel, and is supported in three large bearings.

The pistons are of cast-iron and the case-hardened gudgeon pins are clamped to the small-ends of the connecting rods. A 40-ton steel stamping is used for the crankshaft, this being fitted with a double thrust washer which takes the thrust of the clutch spring when the clutch is disengaged. White-metal liners are used for the big-ends, which are accessible by dropping the sump.

Both the camshaft and magneto are driven by a Renolds silent chain, arranged as a triangular drive from the crankshaft pinion. The method of adjusting this chain is neat and silent. It consists of a special type of jockey pulley embodying a radial ball race having secured to it, by riveted side plates, a ring of Fabroil, which is pressed against the outer face of the chain. This jockey pulley is mounted on an eccentric spindle which carries by splines a lever by which it can be rotated to the desired extent to provide perfect adjustment. A feature of the design is that removal of the timing case does not affect the adjustment.

Ignition is provided by a Simms in

strument, this being secured by a bridge held by nuts on two long studs—a simple and rather more lasting device than the usual steel band fitting. An advance and retard lever and a throttle control are carried in the centre of the steering wheel. At the near side of the timing case is conveniently carried the combined oil filler and breather.

The cooling water is circulated by animpeller pump driven" by an extension of the fan spindle. The fan itself is a steel pressing with numerous blades formed in one with an outer ring which keeps them rigid, fan and pump being driven by a link belt adjusted by sliding the outer flange of the driving pulley. The water outlet to the extension tank of the radiator header is neatly disposed at the front end of the cylinder head casting. This per mits the employment of a small joint and gives a neat appearance to the upper portion of the engine, which is practically flat.

To prevent the entry of dirt, the starter, which is mounted at the off side, is completely enclosed. It meshes with a ring on the flywheel. The lastnamed is of cast-iron with the various settings for timing marked on the rim, sq that they can be made to correspond with the fixed pointer on the cylinder block.

One, filter is conveniently situated at the rear near side, being secured by one nut, and close to this is an oil dipper.

A submerged gear-type oil pump is employed for circulating the oil, which passes up through the pump spindle, through the wall of the crankcase to the filter, and thence back to the camshaft, from which it passes to the three main bearings and through the drilled crankshaft to the big-ends.

The chief sump filter, which is of large size, can be removed without losing the main body of oil, as the act of releasing the nut of this filter enables the spindle on which the nut is carried to run back under the influence of a spring, forcing a valve on it against a seating.

Three springs are employed in the enclosed Ferodo-faed cone clutch, which has a Ferodo-ring clutch stop. Driven from the layshaft of the gearbox is an air pump, which is provided, when necessary, as an extra.

A tube of large diameter forms the propeller shaft. This has two flexiblefabric joints, the chief feature of which is a self-centring device consisting of a ball pin driven into the end of the spider with the ball carried in a cup formed in a nut secured to the other spider.

The final drive is by an overhead worm mounted in a pot-type axle casing.

Both brakes are of the expanding type and act in the same rear-wheel drums. The brake-shoe anchorage, in each case, is brought round the inside of the inner shoe and then carried forward to form a support for the overhanging portion of the brake camshaft. Right and left-hand-threaded adjusters, each with a hand wheel formed at its centre, are provided for both brake rods, and the compensators are of the link type.

Reverting to the axle, this is of the full-floating type, embodying a 40-ton steel stamping and having a reduction ratio of 65 to 1. A stamping of similar steel is also employed for the front axle, which is of the reversed Elliott type with the hubs running on roller bearings.

All the wheels are of the War Office steel-disc type.

The track rod is at the front, and balljoints are used both for this and for the steering rod. Large-capacity oil lubricators are carried above the axle pivots, and the steering gear is of the worm and complete wheel type.

In the radiator, cast-aluminium header, bottom tank and side brackets enclose the gilled vertical tubes, and the whole component is carried on ball trunnions. An interesting feature is that the side brackets are slotted at the top, project slightly and are curved in so that three-ply boards can be carried between them, in front of the tubes, to blank off part of the cooling area during cold weather.

Lubrication throughout, except for the main units, is effected by the Tecalemit grease gun.

One of the features of the design is the excellent ground clearance, this being 91 ins, at the lowest point. The Wheelbase is 10 ft. 6 ins., and the track 4 ft. 8 ins, at the rear and 4 ft. 10 ins. at the front.

The prices are, with solid tyres and electric lighting set, £325, and with 32-in. by 6-in, pneumatic tyres, together with complete spare wheel and lighting set, £350. The extras are mechanical air pump at £10, electric starter at £15.