ITEMS OF INTEREST TO REPAIRERS.

Page 29

If you've noticed an error in this article please click here to report it so we can fix it.

Some Practical Points Suggested by Our Driver and Mechanic Readers.

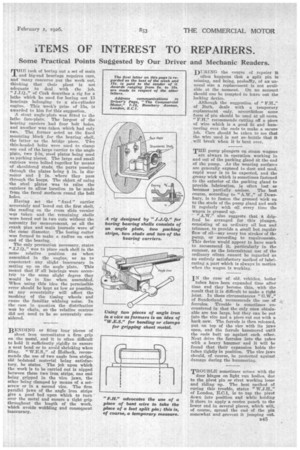

MITE task of boring out a set of main and big-end bearings requires care, and many concerns put the work out, thinking that their plant is not adequate to deal with the job. ".j.j.Q.," of Cork describes a rig for a lathe which he used for boring out 13 bearings belonging to a six-cylinder engine. This week's prize of 15s. is awarded to him for this suggestion.

A stout angle plate was fitted to the lathe face-plate. The largest of the bearing carriers had four bolt holes, and 'another was taken which had only two. The former acted as the fixed mounting block for the bearing shell. the latter as the bridge piece. Tiim thin-headed bolts were used to clamp one end of the large carrier to the angle plate, two g-in. steel plates being used as packing pieces. The large and small carriers were bolted together by means of shouldered studs, the parts passing through the plates being in. in dia meter and in. where they pass through the keeps. The object of mine' the steel plate was to raise the carriers to allow location to be made from the faced Surface's round the bolt holes.

Haying set the "fixed" carrier accurately and 'bored out the first shell, the reading on the cross slide vernier was taken and the remaining shells were bored out in two cuts without the necessity for measurement, as all the crank pins and main journals were of the same diameter. The boring cutter was formed to make a radius on each end of the bearing.

The only precaution necessary, states

was to place each shell in the same relative position as -when assembled in the engine, so as to counteract, any slight inaccuracy In setting up on the angle plate. This meant that if all bearings were eccentric to the same slight degree they would be in line when assembled. When using this idea the permissible error should be kept as low as possible, as any eccentricity will affect the meshing of the timing wheels and cause the familiar whining noise; In the case in question the distribution was by chain, so the relative centres did not need to be so accurately considered.

BENDING or filing long pieces of sheet iron necessitates a firm grip on the metal, and it is often difficult to hold it sufficiently _rigidly to ensure a neat bend or to avoid shrieking when filing. "W.E.S.," of Holbeck, recommends the use of two angle iron strips, old bedstead material being satisfactory, he states. The job upon which the work is to be carried out is nipped between these two iron strips, one end being gripped in the vice jaws, the other being clamped by means of a setscrew or in a second vice. The firm parallel jaws of the angle iron strips give a good bed upon which to turn over the metal and ensure a tight grip throughout the length of the work, which avoids wobbling and consequent inaccuracy. DURING the course of repairs it

often happens that a split pin is missing, and being, proballly, of an unusual size a replacement is not available at the moment. On no account should one be tempted to leave out the

locking device. .

Although the suggestion of " F.H.," of Bath, deals with a temporary replacement only, nevertheless some form of pin should be used at all costs. "F.H." recommends cutting off a piece of wire which is a good fit and hammering over the ends to make a secure job. Care should be taken to see that the wire used is not so brittle that it , will break when it is bent over.

THE pump plungers on steam wagons

are always in operation working in and out of the packing gland at the end of the pump. As the wearing surfaces are generally exposed to dust and mud, rapid wear is to be expected, and the greasy wick which is sometimes fastened to the exterior of the packing gland to provide lubrication, is often lost or becomes partially useless. The best course, according to "A.W.," of Dewsbury, is to fasten the greased wick on to the studs of the pump gland and soak it regularly with oil every time the wagon is greased up.

"A.W." also suggests that a dripfeed be arranged for this plunger, consisting of an ordinary oil box and trimmer, to provide a small but regular flow of oil—say every ten strokes of the pump, or according to requirements. This device would appear to have much to recommend it, particularly in the summer, as the intermittent use of the ordinary oilcan cannot be regarded as an entirely satisfactory method of lubricating a, part which is always in motion when the wagon is working.

IN the case of old, vehicles, boiler tubes have been expanded time after time and they become thin, with the result that it is difficult to make a tight joint. In these circumstances "(1W.," of Sunderland, recommends the use of ferrules. Trouble is sometimes encountered in that the only ones obtainable are too large, but they can be put into the vice and a piece cut out with a hack-saw. The ferrule is then released, put on top of the vice with its jaws open, and the ferrule hammered until the ends butt up against each other. Next drive the ferrules into the tubes with a heavy hammer and it will be found that their expansion holds the tubes tightly in position. The vice jaws should, of course, be protected against damage during the hammering.

TROUBLE sometimes arises with the door hinges on light van bodies, due to the pivot pin or rivet working loose and riding up. The best method of curing this trouble, states "

of London, E.C.1, is to tap the pivot down into position and while holding it there to apply a centre punch to the lower end in several places, which will, of course, spread the end of the pin somewhat and-prevent it jumping out.