MAKING• BEST USE OF THE FORD.

Page 22

If you've noticed an error in this article please click here to report it so we can fix it.

387.—Converting the Axle to a Floating Type.

Several devices have been produced with the object of strengthening the The conversion retails complete at axles of the van and ton truck by making these floating. by the Stentophone Motor Accessories (Inc.), Ombersley Road, Birmingham. A new one has recently been marketed E5 17s. 6d. per pair for the rear-axle unit of the ton truck and 14 17s. 6d. per pair for the delivery van.

The device in question consists of a housing and substantial bearing complete with all bolts and fixings for attaching to the wheel in the manner shown, and it presents the considerable advantage that no structural alterations in the existing axle units are required.

The conversion can actually be carried out to any axle in two or three hours.

Altering the axle in this way will prevent breakage of the axle shafts and reduce the risk of the brakes becoming inefficient through wear on the roller bearings and shaft.

388.—Fitting the Engine Bearings.

When fitting the engine bearings a

little care may save a great deal of trouble in startingthe engine, after the overhaul ; at the same time, the bearing

surfaces will be improved.

Many engines, of course, have their bearings burnt in and are hardly touched by the scraper ; but if this be not clone, then the No. 3 main bearing (i.e., that at the flywheel end) should be bedded down to a good running fit, and the other two left a tight fit, but with their nuts undone slightly. In the same way the No. 4 connecting rod Rhould be well fitted and the others left tight with the nuts slacked back slightly. The , lower portion of the crankcase should, of course, not be replaced until later. The engine can then be started with a swing, and, while running slowly, the loose nuts of the main bearings gradually tightened. Ey using hinges in this manner Of course, so far as the big-ends are the foot brake can be held on and

Plenty of oil should be employed all the time to avoid any risk of seizure. Finally, when sufficiently tight, the nuts should be split-pinned.

389.—Sulphated Batteries and their Treatment.

Storage batteries, accumulators or secondary cells, as they are variously called, are often extremely delicate pieces of apparatus, both mechanically and electrically, although one would scarcely credit this fact, judging by the treatment they so frequently reeeive.

If a battery be allowed to fall, it usually receives considerable damage. If it be left undercharged it will suffer electrically, and if discharged too rapidly 1338 this, the active surface or. the " element " becomes much reduced, and the battery is, in consequence, overworked, finally the plates fall to pieces, and in nine cases out of ten the battery is ruined.

Sulphation at first appears as a whitish deposit on the plates. It is shown also by a failing off in the voltage and in thd current produced, the plates begin to fall to pieces and shortcircuiting between them almost inevit ably ensues.

In the event of sulphation, as in most other things, a stitch in time saves nine, and if the battery be properly treated the trouble may be cured, or, at least, the plates given a new lease of life. Even badly sulphated ex-Government accumulators have been rescued and have given good results without the need for renewing the plates.

Geneeally it is useless to attempt treatment if the snlphation be very bad, but if it has only just been noticed, run off the acid and refill with acid of about 1.10 sp, gr., and recharge at about half the normal rate for some 45 hours, this depending upon the size of the battery ; then run off the electrolyte and refill with acid of 1.205 sp. gr. to 1.220 sp. gr., and again give a good charge. Never scrape the white deposit from the plates, as this spoils their solidity and renders them liable to fall to pieces.

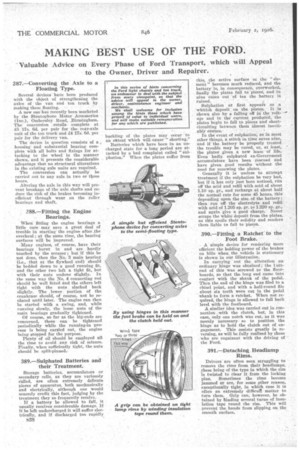

390.—Fitting a Ratchet to the Foot Brake.

A simple device for rendering more efficient the holding power of the brakes on hills when, the vehicle is stationary is shown in our instratiOn.

In carrying out the alteration an ordinary hinge was obtained ; the luttend of this was screwed to the floorboards, so that the long end came into contact with the shank of the pedal. Then the ena of the hinge was filed to a chisel point, and with a half-round file about six teeth were cut in the pedal 'shank to form a ratchet. When not required, the hinge is allowed to fall back level with the footboard.

A similar idea was carried out in connection with the clutch, but, in this case, only one notch was cut, as it was merely necessaryso to position the hinge as to hold the clutch out of engagement. This assiats greatly in reversing, as will be fully realized by those who are cognizant with the driving of the Ford.

391.—Detaching Headlamp Rims.

Drivers are often seen struggling to remove the rims from their headlamps„ these being of the type in which the rim is twisted to clear it from the locking pins. Sometimes the rims become jammed or are, for some ,other reason, exceptionally tight, in which ease it is often an extremely difficult matter to turn them. Grip can,' however, be obtained by binding several turns of insulation tape round the rim. This will prevent the hands from slipping on the smooth surface.