LIGHTENING THE LOAD

Page 58

Page 59

Page 60

Page 61

If you've noticed an error in this article please click here to report it so we can fix it.

Sales of Fts and loaders on 3.5-tonners are booming.

Sharon Clancy checks out the market.

l's taken nearly a decade but predictions that 3.5-tonners will be the next big market for tail-lifts may finally be becoming a reality. In 2004, sales of light tail-lifts are expected to head towards the 6,000 mark: insiders are predicting annual growth of 2-3% a year over the next couple of years.

Which raises the question, what is driving sales in a sector notoriously resistant to using loading aids on the ground of weight,space, time and cost?

For a start, there's legislation, as more employers in the sector become aware of their legal responsibilities under the manual handling regulations and the potential liability cost in the event of an injury.As one operator puts it: 'Providing a loading aid demonstrates an employer has both completed a risk assessment of the manual handling operation and taken steps to protect employees."

Another factor is soaring van sales, some at the expense of 7.5-tonners as companies pick smaller vehicles to cut their running costs. Lifts and loaders can help improve efficiency by enabling one-man deliveries.Terry White, UK sales director for MBB lifts, explains:"One of our customers was double-manning, but fitting a tail-lift has enabled him to switch to a one-man operation and expand the operation by giving the driver's mate his own van."

Del Equipment is market leader in lightweight lifts. Sales manager Paul Kelly confirms sales are growing, but adds that getting the specification right is critical. "There's a huge variety of end-users from road-mending local councils to tool hire companies, all with differing handling requirements."

For panel vans the choice of tail-lift boils down to two options: a cantilever where the platform forms part of the rear closure; or a mounted internal lift that fits inside the rear or side doors, either directly behind or stowed to one side to improve access when not in use. Some internal lifts are adaptations of minibus wheelchair lifts.

On box bodies and dropsiders you can also fit a conventional column lift, either with hydraulic cylinders in the columns or chains.

Internal lifts tend to be lighter than cantilever models, partly because many have small platforms. Typical weight for a cantilever lift is 170-280kg depending on capacity and platform size. Ray Smith's Dutch-designed internal Iezieloader lift, for example, weighs just 95kg,compared with 230kg for its RS5 cantilever lift.

Remember to check ground clearance and the rear overhang before buying a cantilever lift; lack of space is one-reason why power packs are sometimes fitted separately rather than in the beam.

Lift capacities range from 300kg to 750kg. Don't forget that lift capacity reduces where the load centre is further from the rear edge of the platform. Most tail-lift manufacturers' quoted capacities assume the load centre is 600mm from the platform edge.

Maximum lift heights vary from 800 to about 1,200mm , so operators also need to check that the maximum lifting height of the lift is greater than the floor height of the van.

Internal lifts

The twin-pillar Ratcliff RTC350A stows behind the rear doors, as does MBB's Cityftx and Dhollandia's DH-P21.Del's PC3000L is a single-pillar 300kg-capacity lift which bolts in place behind the nearside wheelarch. It does not obstruct access,but the platform stows in front of the wheelarch, so there's a small loss of internal width.

Many internal lifts bolt in place using standard fixing points. Anteo's 400kg-capacity CEJ lift weighs 120kg with a 1,350x1.450mm platform; it features a wireless remote control and is powered by the vehicle battery MBB offers two key van lifts: the Minifix. which is mounted externally, and the internal Cityfix which comes in 500 and 750kg capacities and a range of platform dimensions.

Aluminium platforms dominate the 300kgcapacity market, but steel frames and platforms are available on higher rated lifts where. Kelly reports, they compare favourably on weight.

External lifts

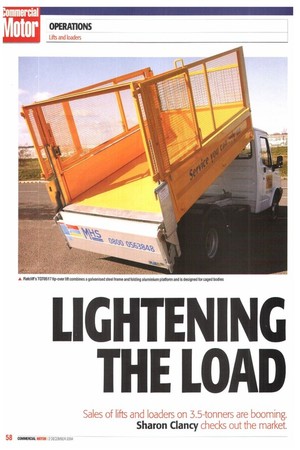

Rateliffs Flexi-Lift range allows operators to mix and match lifts for vans, chassis-cabs, pickups and tippers up to seven tonnes.The RQ517 is among Ratcliffs Lop-sellers: it combines a galvanised steel frame with an aluminium platform and is popular for box bodies and pickups.The all-aluminium RQ518 is available with a folding platform which can be dropped vertically below floor level for faster rear access.

The RQT0517 tip-over lift, which combines a galvanised steel frame and folding aluminium platform, is designed for caged bodies. There are also two tip-through lifts.

Many lifts for dropside and tipper bodies have a folding lift platform to save space and some drop below the loadbed for easy access. Mesh platform like the one on Del's DL5000P lift are popular on mucky jobs like road and pavement repairs because they improve grip.They also allow better rear visibility than a solid platform and have less wind resistance so fuel consumption should be better.

Tipmaster's Tommy lift was one of the first models to use the lift platform as the tailgate. The rams are housed in side columns, so towbars can still be accommodated,and there's no need to remove spare wheels. Capacity is 500kg.

Another 500kg-capacity lift is the Easyloader from Penny Hydraulics. It's designed for Luton and box van bodies, accommodating floor heights up to 990mm, and weighs 99kg with an aluminium platform. Remote and static controls are fitted as standard — a secondary hand pump allows the lift to be lowered manually if there's a problem.

Penny Hydraulics also makes the 340kgcapacity bolt-on Step Lift. It stows away below door level or replaces a full-width rear step and platform, but unfolds to operate as a conventional lift for larger loads.

On Dhollandia's DH-LSP cantilever lift the rams are fitted to the underside of the platform, eliminating the need for cut-outs in the rear bumper. The lift simply bolts to the chassis via hanging plates which are designed for each model; the power pack is premounted in the lift beam to simplify fitting. Capacities range from 300-500kg with an installed weight of about 190kg.

Loaders

Alongside companies such as Atlas-Terex, HMF, Hiab and Pallinger, which are better known for heavy-duty lorry loaders, there are light loader specialists including Penny Hydraulics and Tipmaster.

Light loaders are designed to take up the minimum of space and, depending on the body, you can offload to the side as well as the rear.They can be fully hydraulic or electric, winch-style cranes which are lighter.

All loaders now have safety devices to enhance stability and prevent overloading.so check the loader has the reach and capacity necessary for your operation.

Stabiliser legs will be needed on higher capacity cranes with longer reach— a point to consider if payload is critical.

Penny Hydraulics developed the Swinglift for pickups: it was originally sold by Lucas but is now back in the company's stable. Pick the below-floor mounting option and you can remove the crane when not required to maximise payload and load floor space, giving you the flexibility to use it on a second truck, The SwingLiftV has capacities from 4402000kg and reaches from 1.1-3.5m with manual or hydraulic extension and hydraulic slewing.The unit folds down to the king post when not in use and the oil tanks and motor pump are incorporated into the body.

Tommy's Swift Lift loader was developed for pickups,but is now available for dropsi des and flatbeds. Capacities are 200kg or 300kg;it weighs in at 85-105kg, depending on the model.

Penny Hydraulic's Miniloader 150 and 250kR loaders have a 900mm boom as standard and up to nine metres of cable to handle loads below ground level: for example when lifting kegs from cellars.

Palfinger's revamped Compact range is designed to save weight and space.The PC 1300 electro-hydraulic crane is the smallest model in the range and can lift 440kg at 2.7m, or 300kg at 3.5m.

HMF claims its 2.5-tonne/metre crane is the lightest contender in its class at 325kg. Designed for grab applications, it incorporates HMF's Power Plus link arm system on the boom cylinder, which increases the lifting power by 75% and ensures a uniform lifting effort in the entire working area.

The 50-T series can lift 430kg at 1.15m and weighs just 62kg. Its worm gear is contained in an oil bath for maintenance-free operation. The HMF 150-T lifts 340kg at 2.9m and theTP model is designed for mounting directly on the truck body.

Do nothing: not an option

With such a wide variety of chassis types and bodies up to 3.5 tonnes and a choice of lifts and loaders, doing nothing can be a tempting option.

Not only is this risky if the HSE. decide to pay a calkyou could be missing out on the opportunity to make your operation more efficient. And when the Working Time Directive comes into effect next March, maximising driver productivity will be high on everyone's agenda.