A New Two-stroke Engine

Page 49

If you've noticed an error in this article please click here to report it so we can fix it.

MANY attempts have been made he the past to design a two-strok engine capable of giving as good a h.m.e.p. as the four-stroke type, and thereby developing twice the power for a given cylinder capacity, but so far the various difficulties encountered have proved almost insuperable. However, the designers of a new two-stroke engine known as the Jameson have made a bold bid to solve the problem and have already obtained some excellent results with an experimental single-cylindered unit.

Although of only 411 c.c. net capacity (measured above the piston-controlled exhaust ports) this engine is said to have given 50 b.h.p. at a speed of 5,000 r.p.m.

Such a result implies highly efficient means for supplying the mixture to the cylinder and for exhausting it therefrom. In the Jameson engine these requirements are met in three ways : by employing a supercharger, specially designed for the purpose, by delivering the mixture through a ring of ports which are positively controlled by a crank-driven piston valve, and by exhausting the gases through a number of ports in the cylinder walls uncovered by the main working piston near to the bottom of its stroke.

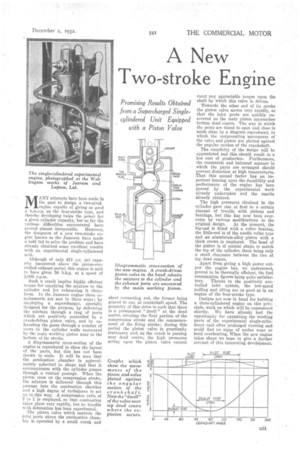

A diagrammatic cross-section of the engine is reproduced to show the layout of the parts, but this has not been drawn to scale. It will be seen that the combustion chamber is approximately spherical in shape and that it communicates with the cylinder proper through a venturi passage. When the piston rises on the compression stroke, the mixture is delivered through this passage into the combustion chamber and a high degree of turbulence is set up in this way. A compression ratio of 7 to 1 is employed, so that combustion takes place very rapidly, but no trouble with detonation has been experienced.

The piston valve which controls the inlet ports above the combustion chamber is operated by a small crank and

short connecting rod, the former being geared to run at crankshaft speed. The geometry of this drive is such that there is a pronounced " dwell " at the dead centre, covering the final portion of the compression stroke and the commencement of the firing stroke; during this period the piston valve is practically stationary and, as the crank is passing over dead centre, the high pressures acting upon the piston valve cannot

exert any appreciable torque upon the shaft by which this valve is driven.

Towards the other end of its stroke the piston valve moves very rapidly, so that the inlet ports are quickly un covered as the main piston approaches bottom dead centre. The way in which the ports are timed to open and close is made clear by a diagram reproduced, in which the reciprocating movements of the valve and piston are plotted against the angular motion of the crankshaft The simplicity of the design will be appreciated and this should result in a low cost of production. Furthermore, the concentric and balanced manner in which the parts are arranged should prevent distortion at high temperatures.

That this second factor has an important bearing upon the durability and performance of the engine has been proved by the experimental work already undertaken and the results already obtained.

The high pressures obtained in the cylinder gave rise at first to a certain amount of trouble with pistons and bearings, but this has now been overcome by various modifications to the original design. At the moment, the big-end is fitted with a roller bearing, the little-end is of the needle roller type and an aluminium-alloy piston with a thick crown is employed. The head of the piston is of conical shape to match

the top of the cylinder, there being only a small clearance between the two at top dead centre.

Apart from giving a high power output the engine has, we understand, proved to be thermally efficient, the fuel consumption figures being quite satisfac tory. Thanks to the positively con trolled inlet system, the low-speed pulling and idling are as good as in an engine of the four-stroke type.

Designs are now in hand for building a three-cylindered engine on this prin ciple, work on which will be commenced shortly. We have already had the opportunity for examining the working parts of the experimental single-cylin dered unit after prolonged running and could find no signs of undue wear or local overheating. When the new engine takes shape we hope to give a further account of this interesting development.