Body swoppers' invasion forces new codes of practice

Page 23

If you've noticed an error in this article please click here to report it so we can fix it.

'ROGRESS is being made owards adopting a set of ,tandards aimed at allowing an nterchange of bodies between lemountable systems from difrent manufacturers.

The need for universal riteria is something which the reight Transport Association as stressed for a long time, arid his new standard is a result of s discussions with the Society If Motor Manufacturers and *raders and the demountable quipment manufacturers.

The proposals have been put orward to the British Standards nstitution, and once they have eceived official sanction the ield is open. Operators are keen in the idea for obvious reasons Ind the manufacturers are also ,nthusiastic because they feel hat more companies will conider switching to demounts if hey will not be tied to one paricular system or manufacturer.

3esign ingenuity

Obviously an ideal standard s impossible to achieve. What an be done, however, is choose system which fixes the mininum number of dimensions, loes not inhibit individual deign ingenuity and gives a free em on the dimensions of the )odywork.

There is a chance that a 'universal' demountable tandard might be influenced by 3erman DIN standards and .loyds testing requirements for ontainers. The use of conainers and/or demountable lodies (and the two are not iecessarily the same) can be livided into two categories: oad/ rail and road/road.

The working party is totally (opposed to any attempt to enforce either the ISO or DIN testing standards upon the road/ road system, as the cost of the body would increase enormously due to it having to meet the road/ rail requirements.

The parties involved are anxious to emphasise that this does not mean that their proposed standard has been skimped with regard to strength and safety. They argue that the stresses involved in road/rail work are much higher and it is totally unnecessary to build a road/road system to the same structural requirements.

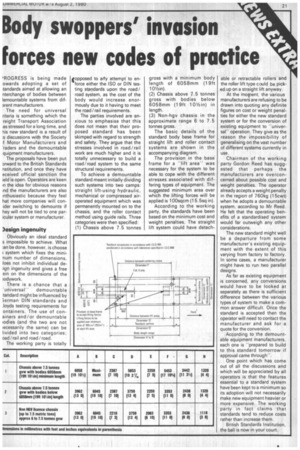

To achieve a demountable standard meant initially dividing such systems into two camps: straight lift-using hydraulic, mechanical or compressed airoperated equipment which was permanently mounted on to the chassis, and the roller contact method using guide rails. Three categories were then specified. (1) Chassis above 7.5 tonnes gross with a minimum body length of 6058mm (19ft 10/2 in).

(2) Chassis above 7.5 tonnes gross with bodies below 6058mm (19ft 101/2in) in length.

(3) Non-hgv chassis in the approximate range 6 to 7.5 tonnes gross.

The basic details of the standard body base frame foe straight lift and roller contact systems are shown in the accompanying diagram.

The provision in the base frame for a "lift areawas necessary for the system to be able to cope with the different stresses associated with differing types of equipment. The suggested minimum area over which the lifting forces will be applied is 100sqcm (15.5sq in).

According to the working party, the standards have been based on the minimum cost and weight penalties. The straight lift system could have detach

able or retractable rollers and the roller lift type could be _ picked up on a straight lift anyway.

At the 'moment, the various manufacturers are refusing to be drawn into quoting any definite figures on cost or weight penalties for either the new standard system or for the conversion of existing equipment to "universal" operation. They give as the reason the impossibility of generalising on the vast number of different systems currently in use.

Chairman of the working party Gordon Reed has suggested that perhaps the manufacturers are overconcerned about possible cost and weight penalties. The operator already accepts a weight penalty in the region of 760kg (15cwt) when he adopts a demountable system, according to Mr Reed. He felt that the operating benefits of a standardised system would far outweigh any other considerations.

The new standard might well be a departure from some manufacturer's existing equipment with the extent of this varying from factory to factory. In some cases, a manufacturer might have to run two parallel designs_ As far as existing equipment is concerned, any conversions would have to be looked at separately as there is sufficient difference between the various types of system to make a common answer difficult. Once the standard is accepted then the operator will need to contact the manufacturer and ask for a quote for the conversion.

According to the demountable equipment manufacturers, each one is "prepared to build to this standard tomorrow if approval came through-.

One point which has come out of all the discussions and which will be appreciated by all operators Is that the features essential to a standard system have been kept to a minimum so its adoption will not necessarily make new equipment heavier or more expensive. The working party in fact claims that standards tend to reduce costs rather than increase them.

British Standards Institution, the ball is now in your court.