Increasing the Performance of Existing Engines

Page 62

If you've noticed an error in this article please click here to report it so we can fix it.

A Resume of Recently Published Patent Specifications That Are Obtainable From the Patent Office, Price is. Each

T"'patents from the Economy Engineering Corporation, c/o 225, Broadway, New York, deal with improvements to standard engines, which although simple in themselves, are claimed to give increased performance with economy in fuel.

The first, No. 461,693, deals with tooling arrangements. The inventor states that the cause of detonation is usually the presence of a hot spot in the cylinder head, and if this be abolished, a higher compression may safely be used. The aim of the design is to modify the cooling system so that all parts of the combustion chamber are in the vicinity of 400 degrees F., instead of the usual range of from 250 degrees to 600 degrees F. The drawing shows how the modifications are made, consisting of the casting-in of lead pads (1); these decrease the cooling flow in places and increase it in others, assuming a constant pump supply.

In the second patent. No. 461,694, a feature of oil-engine practice is copied in respect of combustion arrangements. This consists of the use of a combustion-initiating chamber (1) housing the sparking plug, and leading to the main space via a restricting venturi. In action, the sparking plug ignites the small charge in the chamber, which, in turn, projects a blast of flame and gives a large area for starting the combustion of the main charge.

New Oil-engine Combustion-chamber.

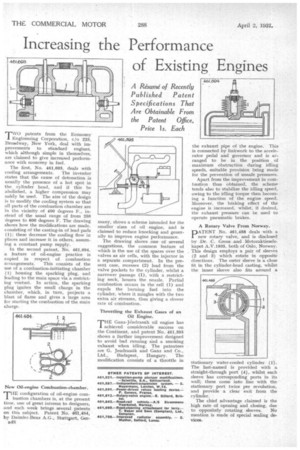

THE configuration of oil-engine combustion chambers is, at the present time, one of great interest to designers, and each week brings several patents on this subject. Patent No. 461,484, by Daimler-Benz A.G., Stuttgart, Ger

B48 many, shows a scheme intended for the smaller sizes of oil engine, and is claimed to reduce knocking and generally to improve engine performance.

The drawing shows one of several suggestions, the common feature of which is the use of the spaces over the valves as air cells, with the injector in a separate compartment. In the present case, recesses (2) lead from the valve pockets to the cylinder, whilst a narrower passage (1), with a restricting neck, houses the nozzle. Partial combustion occurs in the cell (1) and expels the burning fuel into the cylinder, where it mingles with the two extra air streams, thus giving a slower rate of combustion.

Throttling the Exhaust Gases of an Oil Engine.

THE Ganz-jendrassik oil engine has achieved considerable success on the Continent, and patent No. 461,595 shows a further improvement designed to avoid bad running and a smoking exhaust when idling. The patentees are G. jeudrassik and Ganz and Co., Ltd., Budapest, Hungary. The modification consists of a throttle in

the exhaust pipe of the engine. This is connected by linkwork to the accelerator pedal and governor and is arranged to be in the position , of maximum obstruetion during idling speeds, suitable provision being made for the prevention of unsafe pressures.

Apart from the improvement in combustion thus obtained, the scheme tends also to stabilize the idling speed, owing to the idling torque then becoming a function of the engine speed. Moreover, the braking effect of the engine is increased, whilst, if desired, the exhaust pressure can be used to operate pneumatic brakes.

A Rotary Valve From Norway.

DATENT No. 461,488 deals with a

new rotary valve, and is disclosed by .Dr. C. Gross and Motoraktieselskapet A.V.1935, both of Oslo, Norway. This design employs a pair of sleeves (2 and 3) which rotate in opposite directions. The outer sleeve is a close fit in the cylinder-head casting, whilst the inner sleeve also fits around a

stationary water-cooled cyl-nder (1). The last-named is provided with a straight-through port (4), whilst each sleeve has corresponding ports in its wall; these come into line with the stationary port twice per revolution, and provide a clear exit from the cylinder.

The chief advantage claimed is the high rate of opening and closing, due to oppositely rotating sleeves. No mention is made of special sealing devices.